-

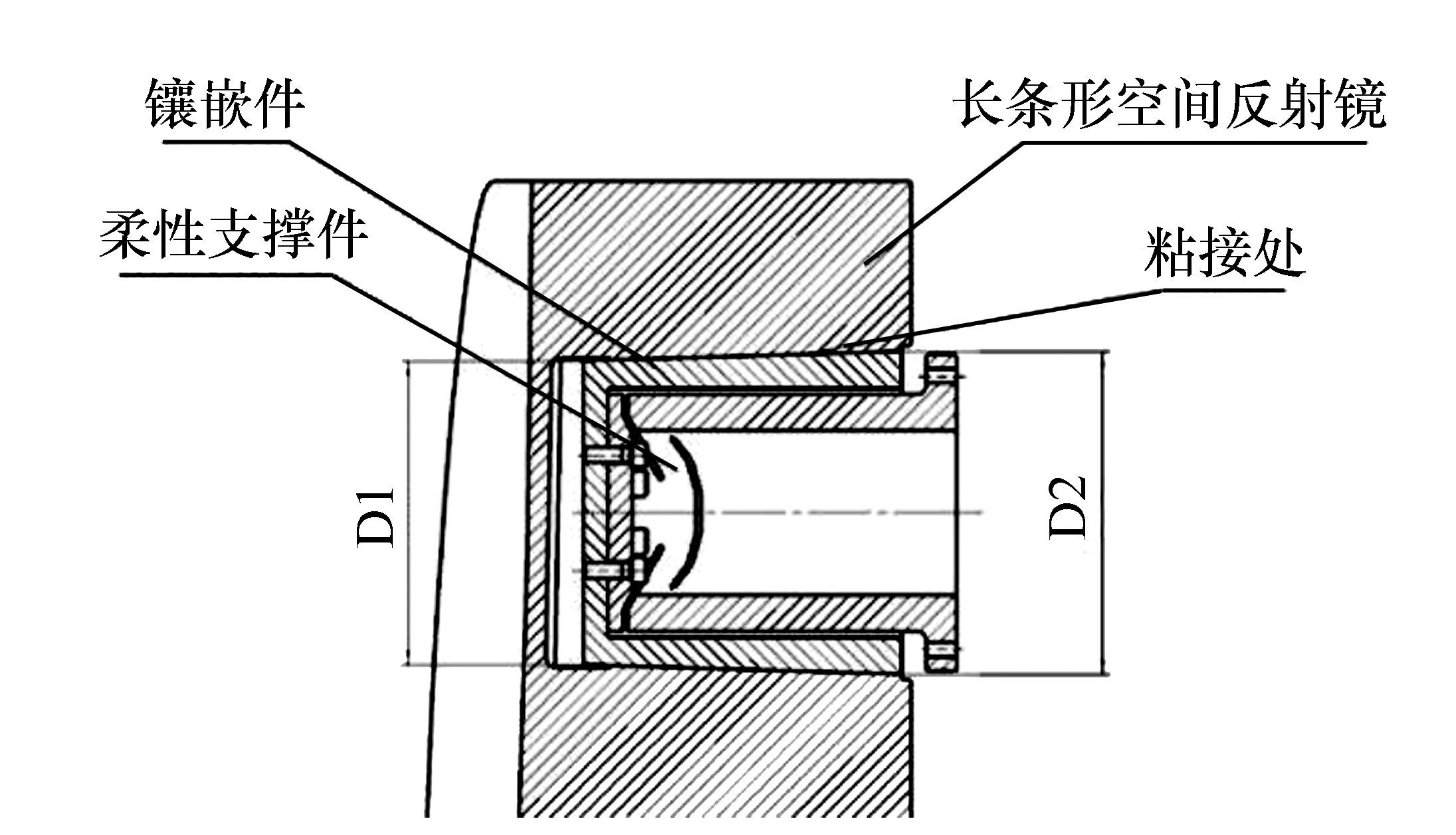

摘要: 为了实现尺寸为1 200 mm×484 mm的大长宽比长条形空间反射镜的无热装配,减小反射镜面形精度受热应力的影响,本文对环氧胶(GHJ-01(Z))胶层厚度对反射镜面形的影响及胶层在静、动力学载荷下的应力进行了研究。首先,介绍了现有的几种基于胡克定律推导的无热粘结厚度方程及其假设条件,并推导了带有锥度的背部盲孔反射镜无热粘结胶层厚度的方程,得出无热粘结胶层厚度曲线;然后,建立了6种不同胶层厚度的反射镜组件模型并进行了分析与比较。通过分析,在+5℃温升工况下,反射镜胶层厚度为0.07 mm时具有最好的面形精度,其RMS值0.0178λ,其检测方向在自重作用下的面形精度RMS值为0.0173λ,一阶频率为220.17 Hz;最后对胶层无热化设计后的反射镜组件进行了振动试验和粘结剂剪切强度试验,分析与试验表明:反射镜组件一阶频率为216.4 Hz,与有限元分析结果相对误差为1.71%;满足动静态刚度要求;同时,在动力学载荷下该厚度胶层的应力均小于其固化后的抗剪强度,安全裕度为2.46;各项指标满足设计要求。Abstract: In order to realize the athermal assembling of rectangular special mirror with large dimension of 1 200 mm×485 mm, and reduce the effect of hot stress on primary mirror's surface figure precision, the effect of epoxy thickness on the surface figure accuracy of the mirror and the stress of epoxy under static and dynamic conditions are researched. First of all, several already existing athermal adhesive thickness equations obtained based on Hooke's law are introduced. The athermal adhesive thickness equations of the primary mirror which has blind holes with taper in the back is developed, and the curve of athermal adhesive thickness is obtained. Then six modes of mirror with different adhesive thickness are made. The result of analysis shows that the mirror's RMS are 0.0178λ(optical value) and 0.0173λ(gravity in detecting's directions) under 5℃ uniform temperature rise when the epoxy thickness is 0.07 mm. Finally, vibration tests of mirror components and drawing test of epoxy are conducted. Analysis and experiment results indicate that its first order frequency is 216.4 Hz and the error between them is 1.71%. The maximum stress of epoxy under dynamic conditions is smaller than the shear strength which is 30.2 MPa, obtained through drawing test of Epoxy, and the safety margin is 2.46. All indicators meet the design requirements.

-

Key words:

- space mirror /

- epoxy adhesive /

- athermalization /

- finite element analysis /

- static and dynamic analysis

-

表 1 材料属性参数

Table 1. Material property parameters

ρ/(kg·mm-3) E/MPa α/(10-6·℃-1) ν SiC 3.05×10-6 3.30×105 2.7 0.27 4J32 8.10×10-6 1.41×105 2.4 0.25 Epoxy 1.22×10-6 158.62(20 ℃) 72(≧20 ℃) 0.495 TC4 4.40×10-6 1.09×105 9.1 0.34 表 2 反射镜在重力场下的分析结果

Table 2. Analysis results of mirror under gravity

X向 Y向 Z向 RMS 0.0062λ 0.0173λ 0.0355λ PV 0.0268λ 0.0843λ 0.1643λ 表 3 反射镜组件的模态

Table 3. Mode of primary mirror assembly

阶数 频率/Hz 振型 1 220.17 反射镜绕Z轴摆动 2 246.56 反射镜绕Y轴摆动 3 253.05 反射镜沿Y向振动 表 4 反射镜组件中胶层的峰值应力和最大应力

Table 4. Peak and maximum stress of epoxy in the primary mirror assembly

X向 Y向 Z向 正弦峰值应力/MPa 9.2 10.9 12.3 最大随机应力/MPa 5.1 6.9 8.6 表 5 随机振动试验的力学条件

Table 5. Mechanical condition of random vibration test

频率范围/Hz 功率谱密度/(g2·Hz-1) 总均方根值/(gRMS) 10~60 +3.0 dB/oct 60~200 0.12 200~300 ↘ 8.2 300~800 0.04 800~2 000 -6.0 dB/oct -

[1] 刘强,何欣.反射镜用光学环氧胶粘接固化工艺研究[J].机械设计与制造,2011,2:118-120. http://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ201102049.htmLIU Q,HE X. Investigation on solidification technics of pastern in space mirror[J]. Machinery Design and Manufacture,2011,2:118-120.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ201102049.htm [2] 中国航空材料手册编委会.中国航空材料手册[M].第8卷,第二版.北京:中国标准出版社,443-445.Editorial Committee of Aeronautical Materials of China. Aeronautical Materials Handbook of China[M]. Volume 8,second edition. Beijing:Chinese Standard Press,443-445.(in Chinese) [3] 肖艳.环氧树脂分类、应用领域及市场前景[J].化学工业,2014,32(9):19-24. http://www.cnki.com.cn/Article/CJFDTOTAL-HGJJ201409008.htmXIAO Y. Classification、Application field and Market prospect of Epoxy[J]. Chemical Industry,2014,32(9):19-24.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-HGJJ201409008.htm [4] RYABOY V M. Analysis of thermal stress and deformation in elastically bonded optics[J]. SPIE,2007,6665:66650K. http://cn.bing.com/academic/profile?id=1996830515&encoded=0&v=paper_preview&mkt=zh-cn [5] BARYAR M. Lens barrel opto-mechanical design principles[J]. Optical Engineering,1984,20(2):181-186. [6] 辛宏伟,关英俊,李景林,等.大孔径长条反射镜支撑结构的设计[J].光学精密工程,2011,19(7):1560-1567. doi: 10.3788/OPE.XIN H W,GUAN Y J,LI J L,et al.. Design of support for large aperture rectangular mirror[J]. Opt. Precision Eng.,2011,19(7):1560-1567.(in Chinese) doi: 10.3788/OPE. [7] HEREBERT J J. Techniques for deriving optimal bond lines for athermal bonded mounts[J]. SPIE,2006,6288:62880J. [8] PENG X,VIEGAS J. Silicon photonics athermal Mach-Zehnder interferometer with wide thermal and spectral operating range[J]. SPIE,2015,9367:936715-7. http://cn.bing.com/academic/profile?id=2079992418&encoded=0&v=paper_preview&mkt=zh-cn [9] VLASENKO O,ZVEREV A,SACHKOV M. Using the DP-190 glue for adhesive attachment of a large space mirror and its rim[J]. SPIE,2015,91513I:1-6. [10] VUKOBRATOVICH D,FETTERHOFF K A,MYERS J R,et al.. Bonded mounts for small cryogenic optics[J]. SPIE,2000,4131:228-239. http://cn.bing.com/academic/profile?id=1979453841&encoded=0&v=paper_preview&mkt=zh-cn [11] 范志刚,常虹,陈守谦,等.透镜无热装配中粘接层的设计[J].光学精密工程,2011,19(11):2573-2581. doi: 10.3788/OPE.FAN ZH G,CHANG H,CHEN SH Q. Design of bonding adhesive in lens athermal mount[J]. Opt. Precision Eng.,2011,19(11):2573-2581.(in Chinese) doi: 10.3788/OPE. [12] 赵伶丰,白光明.复合材料胶接头分析研究[J].航天器环境工程,2007,24(6):393-396. http://www.cnki.com.cn/Article/CJFDTOTAL-HTHJ200706022.htmZHAO L F,BAI G M. Analysis and research of the composite adhesive joints[J]. Spacecraft Environment Engineering,2007,24(6):393-396.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-HTHJ200706022.htm [13] 邵亮,杨飞,王富国,等.1.2 m轻量化SiC主镜支撑系统优化设计[J].中国光学,2012,5(3):229-234. http://www.chineseoptics.net.cn/CN/abstract/abstract8825.shtmlSHAO L,YANG F,WANG F G,et al.. Design and optimization of supporting system for 1.2 m lightweight SiC primary mirror[J]. Chinese Optics,2012,5(3):229-234.(in Chinese) http://www.chineseoptics.net.cn/CN/abstract/abstract8825.shtml [14] 刘强,何欣,张峰,等.反射镜无热装配中胶层厚度的计算及控制[J].光学精密工程,2012,20(10):2229-2235. doi: 10.3788/OPE.LIU Q,HE X,ZHANG F,et al.. Calculation and control of adhesive adhesive in reflector athermal mount[J]. Opt. Precision Eng.,2012,20(10):2229-2235.(in Chinese) doi: 10.3788/OPE. [15] 赵鹏,吴清文,卢锷,等.航天相机主镜热特性研究[J].光学精密工程,1997,5(6):64-68. http://www.cnki.com.cn/Article/CJFDTOTAL-GXJM706.011.htmZHAO P,WU Q W,LU E,et al.. Study on the thermal characteristics of the space camera reflector[J]. Opt. Precision Eng.,1997,5(6):64-68.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-GXJM706.011.htm [16] 刘磊,马军,郑玉权.空间微重力下离轴三反相机离焦范围[J].中国光学,2014,7(2):320-325. http://www.chineseoptics.net.cn/CN/abstract/abstract9135.shtmlLIU L,MA J,ZHENG Y Q. Defocus range of off-axis three-mirror anastigmat(TMA) camera under space microgravity[J]. Chinese Optics,2014,7(2):320-325.(in Chinese) http://www.chineseoptics.net.cn/CN/abstract/abstract9135.shtml [17] 关英俊,辛宏伟,李志来,等.大口径空间反射镜组件结构设计与分析[J].激光与红外,2014,44(7):777-782. http://www.cnki.com.cn/Article/CJFDTOTAL-JGHW201407017.htmGUAN Y J,XIN H W,LI ZH L,et al.. Structural design and analysis of large aperture mirror subassembly[J]. Laser and Infrared,1997,5(6):64-68. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-JGHW201407017.htm -

下载:

下载: