3-D morphological feature measurement and reconstruction of wear particles using multi-view polarized optical coherence tomography

doi: 10.37188/CO.EN-2025-0018

-

摘要:

滑油中的磨粒形貌信息对航空发动机的磨损状态检测和故障诊断至关重要,如何准确地获取滑油磨粒完整的三维形貌信息已经成为滑油磨粒分析的重点。基于以上背景,本文提出了一种基于多角度偏振敏感光学相干层析成像技术的航空发动机滑油磨粒三维形貌检测和重建方法。通过多角度成像采集磨粒的三维形貌信息,运用滤波、锐化、轮廓识别得到点云数据,随后结合多种配准算法和泊松重建方法,生成高精度滑油磨粒三维模型。在实现滑油磨粒三维形貌信息准确重建的同时解决了磨粒遮挡造成的信息丢失问题,保证了重建模型的完整性。此外,通过采集航空发动机滑油中的典型金属及其氧化物的偏振信息,结合斯托克斯矢量、偏振均匀度、累计相位延迟分析对磨粒的偏振特性进行了全面表征和对比分析,实现了对滑油磨粒的多维度信息获取,为磨粒种类识别提供了有效的方法。

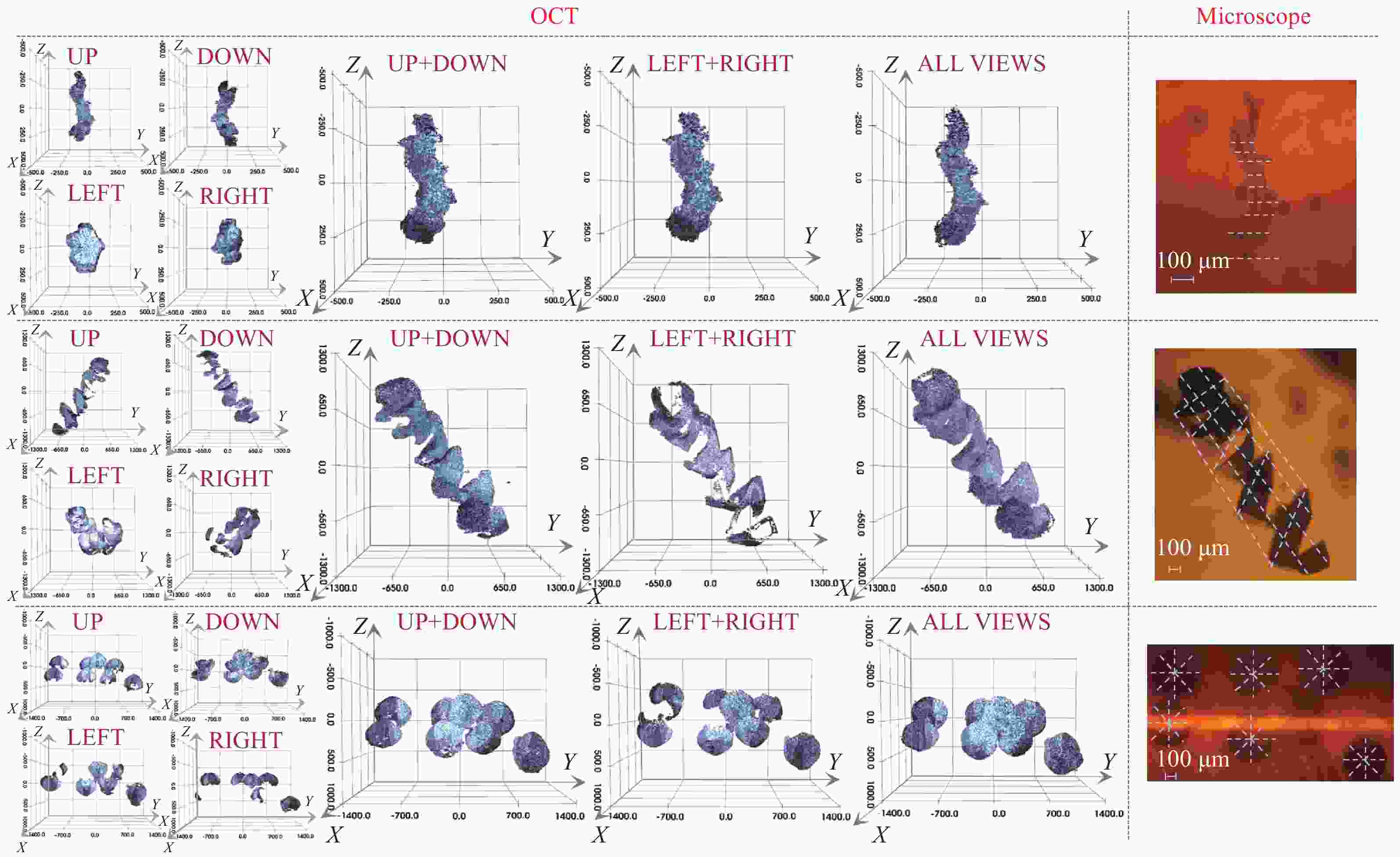

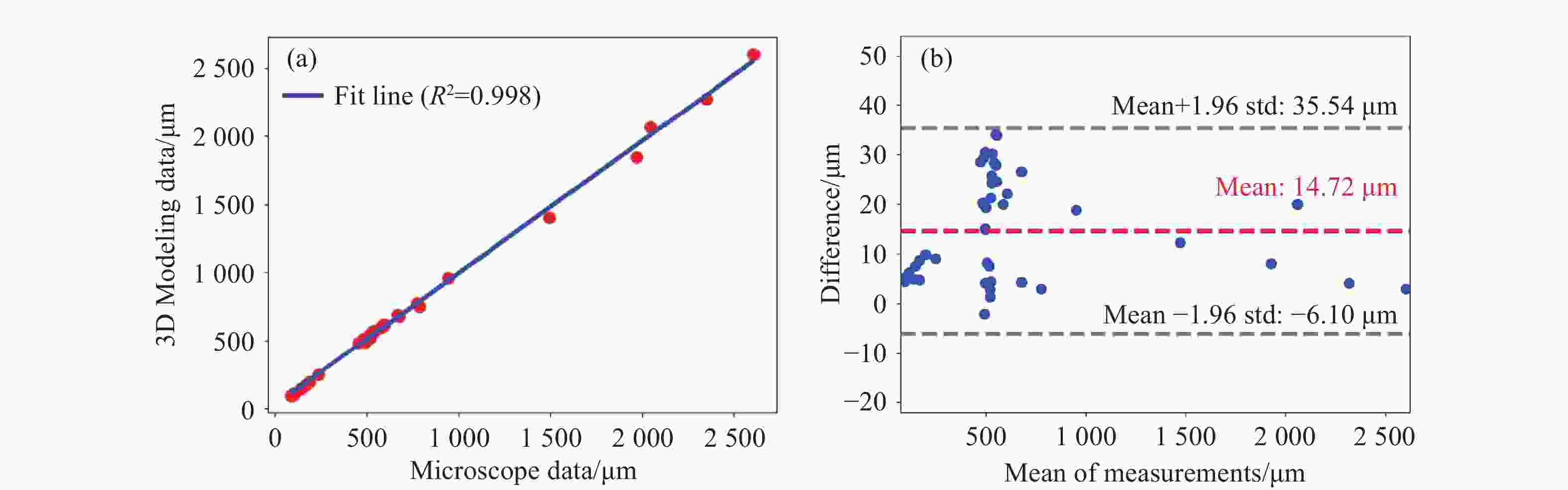

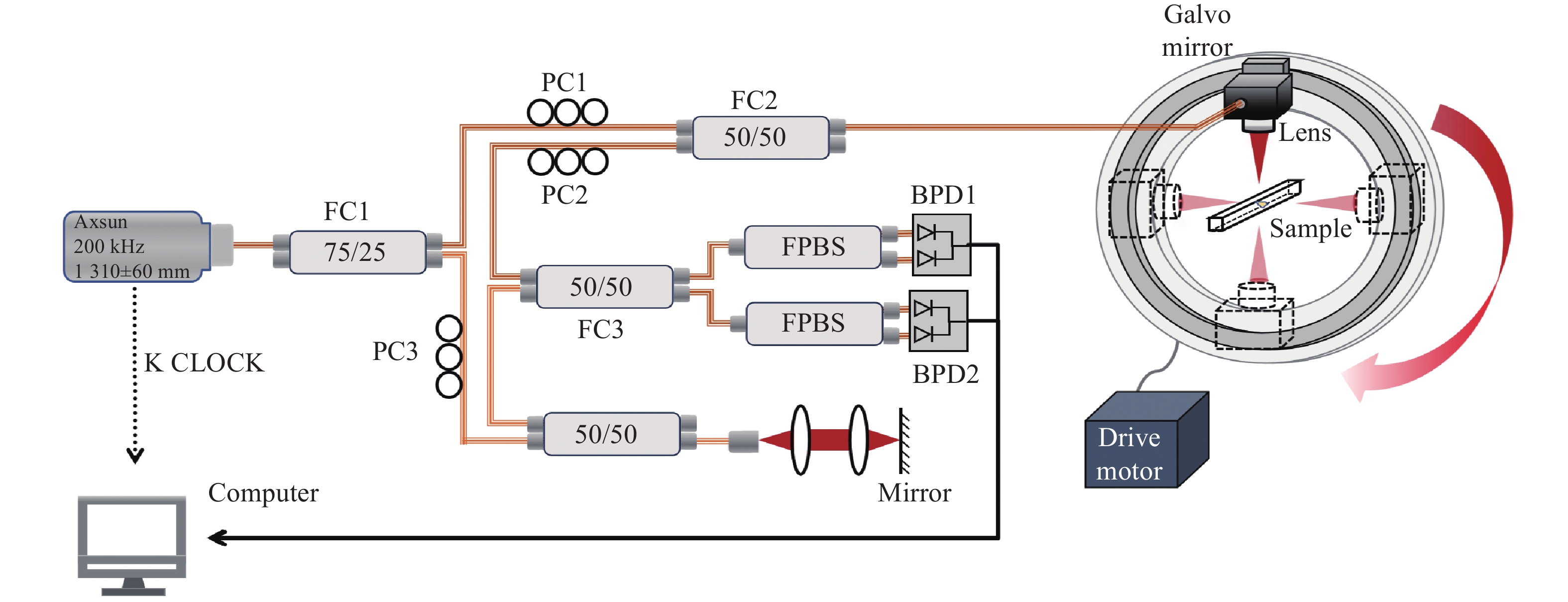

Abstract:The morphological description of wear particles in lubricating oil is crucial for wear state monitoring and fault diagnosis in aero-engines. Accurately and comprehensively acquiring three-dimensional (3D) morphological data of these particles has became a key focus in wear debris analysis. Herein, we develop a novel multi-view polarization-sensitive optical coherence tomography (PS-OCT) method to achieve accurate 3D morphology detection and reconstruction of aero-engine lubricant wear particles, effectively resolving occlusion-induced information loss while enabling material-specific characterization. The particle morphology is captured by multi-view imaging, followed by filtering, sharpening, and contour recognition. The method integrates advanced registration algorithms with Poisson reconstruction to generate high-precision 3D models. This approach not only provides accurate 3D morphological reconstruction but also mitigates information loss caused by particle occlusion, ensuring model completeness. Furthermore, by collecting polarization characteristics of typical metals and their oxides in aero-engine lubricants, this work comprehensively characterizes and comparatively analyzes particle polarization properties using Stokes vectors, polarization uniformity, and cumulative phase retardation, and obtains a three-dimensional model containing polarization information. Ultimately, the proposed method enables multidimensional information acquisition for the reliable identification of abrasive particle types.

-

Key words:

- multi-view /

- optical low coherence /

- polarization /

- 3D reconstruction /

- wear particles

-

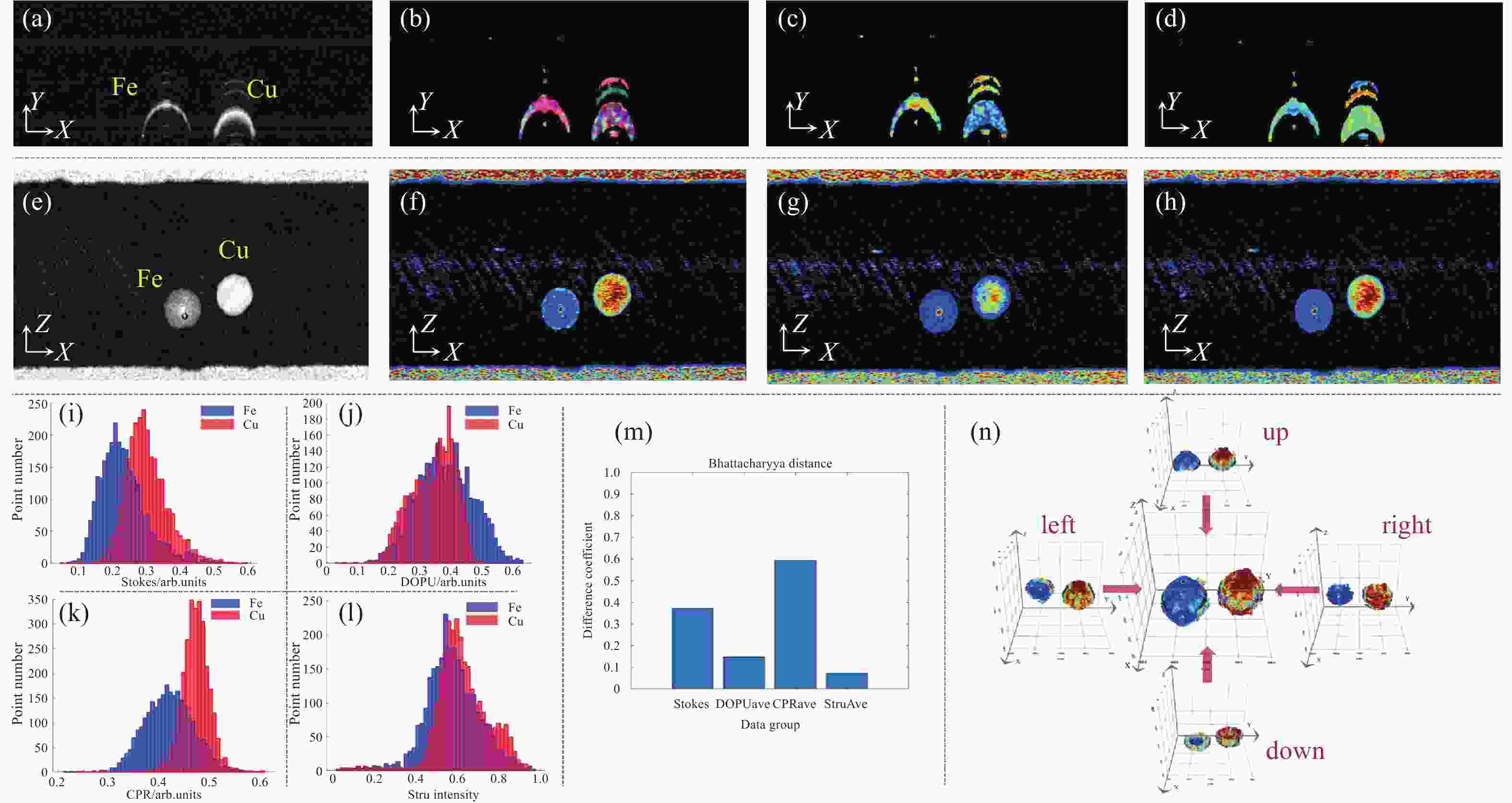

Figure 6. Polarization analysis of spherical copper and iron wear particles. (a) Stru cross-sectional image; (b) Stokes cross-sectional image; (c) DOPU cross-sectional image; (d) CPR cross-sectional image; (e) Stru en-face image; (f) Stokes en-face image; (g) DOPU en-face image; (h) CPR en-face image; (i) Stokes signal strength histogram; (j) DOPU signal strength histogram; (k) CPR signal strength histogram; (l) Stru signal strength histogram; (m) Bhattacharyya Distance Histogram; (n) Polarimetric 3D Model

Figure 7. Polarization analysis of iron and ferric oxide clusters. (a) Stru cross-sectional image; (b) Stokes cross-sectional image; (c) DOPU cross-sectional image; (d) CPR cross-sectional image; (e) Stru en-face image; (f) Stokes en-face image; (g) DOPU en-face image; (h) CPR en-face image; (i) Stokes signal strength histogram; (j) DOPU signal strength histogram; (k) CPR signal strength histogram; (l) Stru signal strength histogram; (m) Bhattacharyya Distance Histogram; (n) Polarimetric 3D Model

-

[1] TAHAN M, TSOUTSANIS E, MUHAMMAD M, et al. Performance-based health monitoring, diagnostics and prognostics for condition-based maintenance of gas turbines: a review[J]. Applied Energy, 2017, 198: 122-144. [2] LIU M R, SUN T, SUN X M. Brain-inspired spike echo state network dynamics for aero-engine intelligent fault prediction[J]. IEEE Transactions on Instrumentation and Measurement, 2023, 72: 3516313. [3] CAO W, ZHANG H, WANG N, et al. The gearbox wears state monitoring and evaluation based on on-line wear debris features[J]. Wear, 2019, 426-427: 1719-1728. [4] SONG J, CHEN F F, LIU Y H, et al. Insight into the wear particles of PEEK and CFRPEEK against UHMWPE for artificial cervical disc application: morphology and immunoreaction[J]. Tribology International, 2020, 144: 106093. [5] WU H K, LI R W, KWOK N M, et al. Restoration of low-informative image for robust debris shape measurement in on-line wear debris monitoring[J]. Mechanical Systems and Signal Processing, 2019, 114: 539-555. [6] KUMAR A, GHOSH S K. Size distribution analysis of wear debris generated in HEMM engine oil for reliability assessment: a statistical approach[J]. Measurement, 2019, 131: 412-418. [7] SARDAR S, KARMAKAR S K, DAS D. High stress abrasive wear characteristics of Al 7075 alloy and 7075/Al2O3 composite[J]. Measurement, 2018, 127: 42-62. [8] WU T H, PENG Y P, WU H K, et al. Full-life dynamic identification of wear state based on on-line wear debris image features[J]. Mechanical Systems and Signal Processing, 2014, 42(1-2): 404-414. [9] EBERSBACH S, PENG Z, KESSISSOGLOU N J. The investigation of the condition and faults of a spur gearbox using vibration and wear debris analysis techniques[J]. Wear, 2006, 260(1-2): 16-24. [10] ZHANG Y L, MAO J H, XIE Y B. Engine wear monitoring with OLVF[J]. Tribology Transactions, 2011, 54(2): 201-207. [11] WU J P, PENG ZH X. Investigation of the geometries and surface topographies of UHMWPE wear particles[J]. Tribology International, 2013, 66: 208-218. [12] QIU X, TARIQ N U H, WANG J Q, et al. Microstructure, microhardness and tribological behavior of Al2O3 reinforced A380 aluminum alloy composite coatings prepared by cold spray technique[J]. Surface and Coatings Technology, 2018, 350: 391-400. [13] WU T H, PENG Y P, WANG SH, et al. Morphological feature extraction based on multiview images for wear debris analysis in on-line fluid monitoring[J]. Tribology Transactions, 2017, 60(3): 408-418. [14] PENG Y P, WU ZH B, CAO G ZH, et al. Three-dimensional reconstruction of wear particles by multi-view contour fitting and dense point-cloud interpolation[J]. Measurement, 2021, 181: 109638. [15] WANG SH, WU T H, WANG K P, et al. 3-D particle surface reconstruction from multiview 2-D images with structure from motion and shape from shading[J]. IEEE Transactions on Industrial Electronics, 2021, 68(2): 1626-1635. [16] WU H K, LI R W, LIU SH L, et al. Three dimensional shape measurement of wear particle by iterative volume intersection[J]. Proceedings of SPIE, 2017, 10615: 106153Q. [17] HU M Y, YANG D, YANG Z H, et al. Polarization-sensitive optical coherence tomography for oral squamous cell carcinoma tissue imaging[J]. Acta Optica Sinica, 2022, 42(10): 1017002. (in Chinese). [18] LIPPOK N, VILLIGER M, JUN CH S, et al. Single input state, single-mode fiber-based polarization-sensitive optical frequency domain imaging by eigenpolarization referencing[J]. Optics Letters, 2015, 40(9): 2025-2028. [19] JIAO SH L, YAO G, WANG L V. Depth-resolved two-dimensional Stokes vectors of backscattered light and Mueller matrices of biological tissue measured with optical coherence tomography[J]. Applied Optics, 2000, 39: 6318-6324. [20] GÖTZINGER E, PIRCHER M, GEITZENAUER W, et al. Retinal pigment epithelium segmentation by polarization sensitive optical coherence tomography[J]. Optics Express, 2008, 16(21): 16410-16422. doi: 10.1364/OE.16.016410 [21] EVERETT M J, SCHOENENBERGER K, COLSTON B W, et al. Birefringence characterization of biological tissue by use of optical coherence tomography[J]. Optics Letters, 1998, 23(3): 228-230. [22] CANNY J. A computational approach to edge detection[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 1986, PAMI-8(6): 679-698. [23] YU H C, GAO J L, LI A T. Probability-based non-local means filter for speckle noise suppression in optical coherence tomography images[J]. Optics Letters, 2016, 41: 994-997. [24] FISCHLER M A, BOLLES R C. Random sample consensus: a paradigm for model fitting with applications to image analysis and automated cartography[J]. Communications of the ACM, 1981, 24(6): 381-395. doi: 10.1145/358669.358692 [25] BESL P J, MCKAY N D. A method for registration of 3-D shapes[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 1992, 14(2): 239-256. doi: 10.1109/34.121791 [26] CHEN Y, MEDIONI G. Object modelling by registration of multiple range images[J]. Image and Vision Computing, 1992, 10(3): 145-155. doi: 10.1016/0262-8856(92)90066-C [27] ZHAN SH, CHANG L L, ZHAO J J, et al. Real-time 3D face modeling based on 3D face imaging[J]. Neurocomputing, 2017, 252: 42-48. doi: 10.1016/j.neucom.2016.10.091 [28] WANG X, LI Y, PENG Y X, et al. A coarse-to-fine generalized-ICP algorithm with trimmed strategy[J]. IEEE Access, 2020, 8: 40692-40703. doi: 10.1109/ACCESS.2020.2976132 [29] FRANÇOIS G, PHILIPPE R, GUILLAUME D. Bhattacharyya distance as a contrast parameter for statistical processing of noisy optical images[J]. Journal of the Optical Society of America A, 2004, 21(7): 1231-1240. doi: 10.1364/JOSAA.21.001231 [30] PENG X C, FEI Y W, WU N, et al. Preprocessing methods of determination of wear elements in aviation lubricants by ICP-AES[J]. Synthetic Lubricants, 2017, 44(4): 37-39. (in Chinese). [31] HOU ZH Q, XUE L T, LIU W L. The fault parts identifying of aero-engine based on the lubricating oil spectral data[J]. Lubrication Engineering, 2010, 35(1): 89-92. (in Chinese). [32] HE Y B, FENG W W, JIANG K. Simulation of inductive sensor for wear debris recognition in aero-engine lubricating oil[J]. Computer Simulation, 2015, 32(10): 39-42,112. (in Chinese). [33] PENG P, WANG J G. Analysis of oxide wear debris using ferrography image segmentation[J]. Industrial Lubrication and Tribology, 2019, 71(7): 901-906. doi: 10.1108/ILT-09-2018-0355 [34] CHEN G, ZUO H F. Diagnosis of wear-induced breakdown of machine by spectrometric analysis based on artificial neural network[J]. Tribology, 2004, 24(3): 263-267. (in Chinese). [35] SU X G, YAN X, TSAI C L. Linear regression[J]. WIREs Computational Statistics, 2012, 4(3): 275-294. doi: 10.1002/wics.1198 [36] GIAVARINA D. Understanding bland Altman analysis[J]. Biochemia Medica, 2015, 25(2): 141-151. doi: 10.11613/BM.2015.015 -

下载:

下载: