Development of a Low-Temperature, High-Performance Coating Process for Heat-Sensitive Substrates

-

摘要:

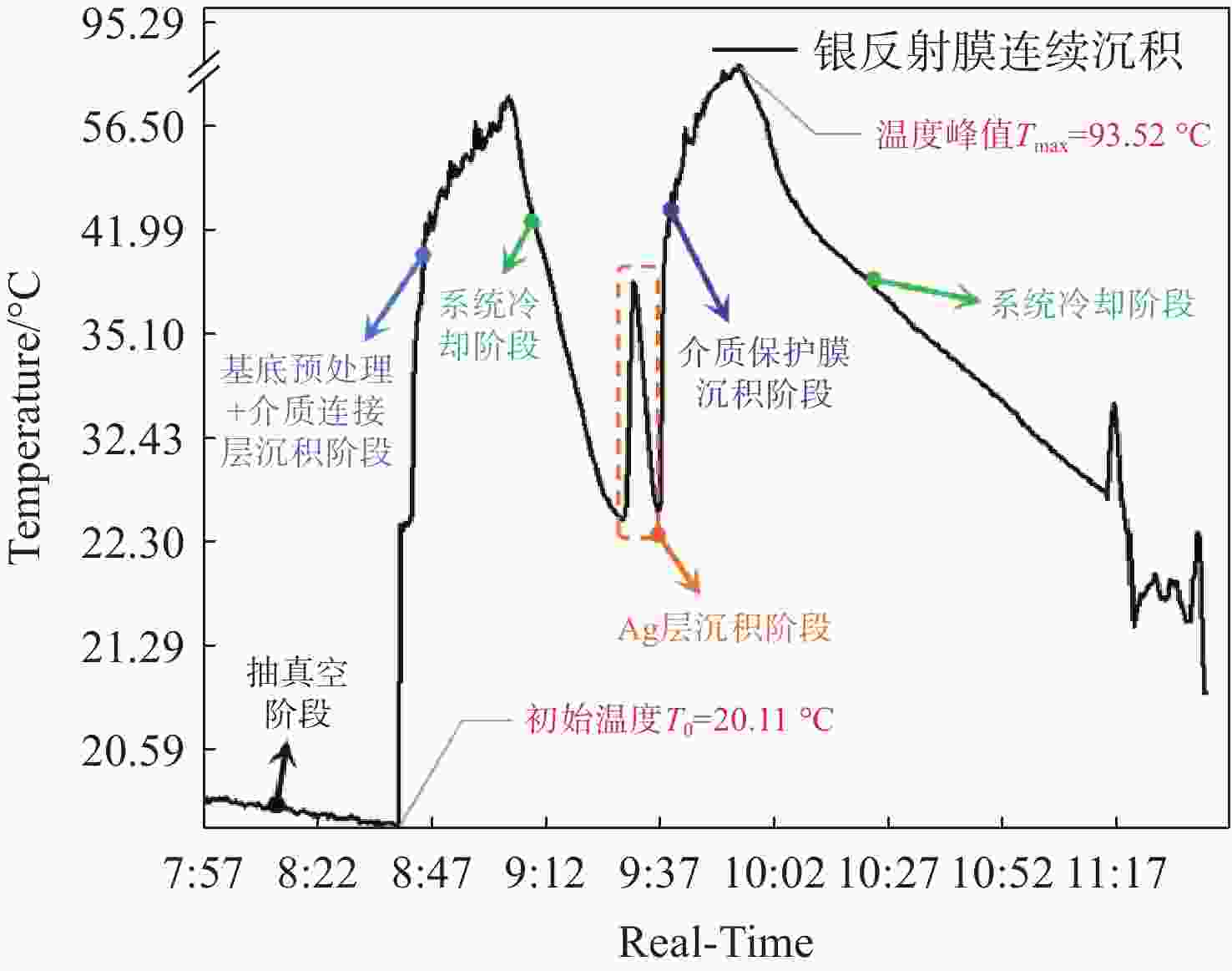

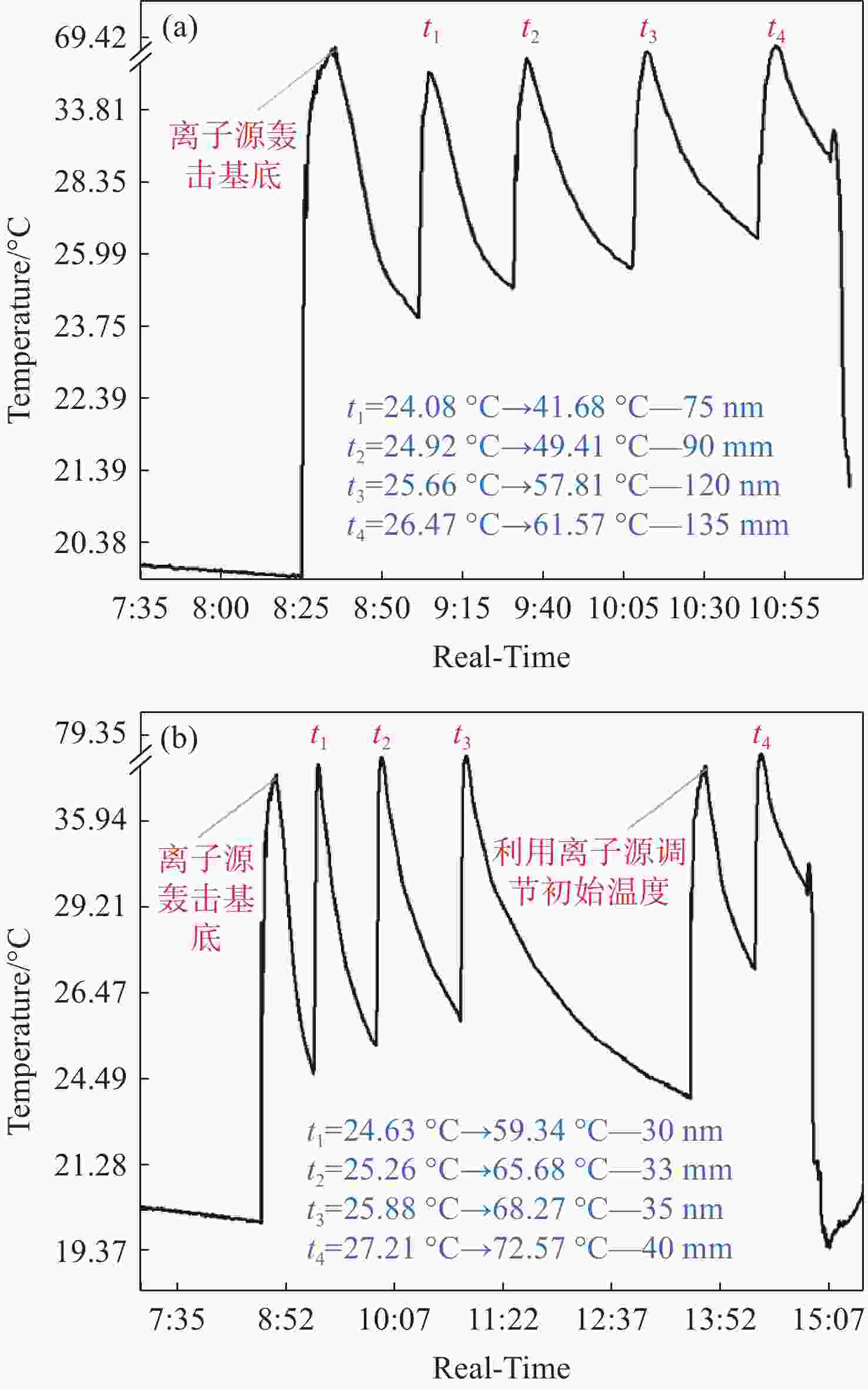

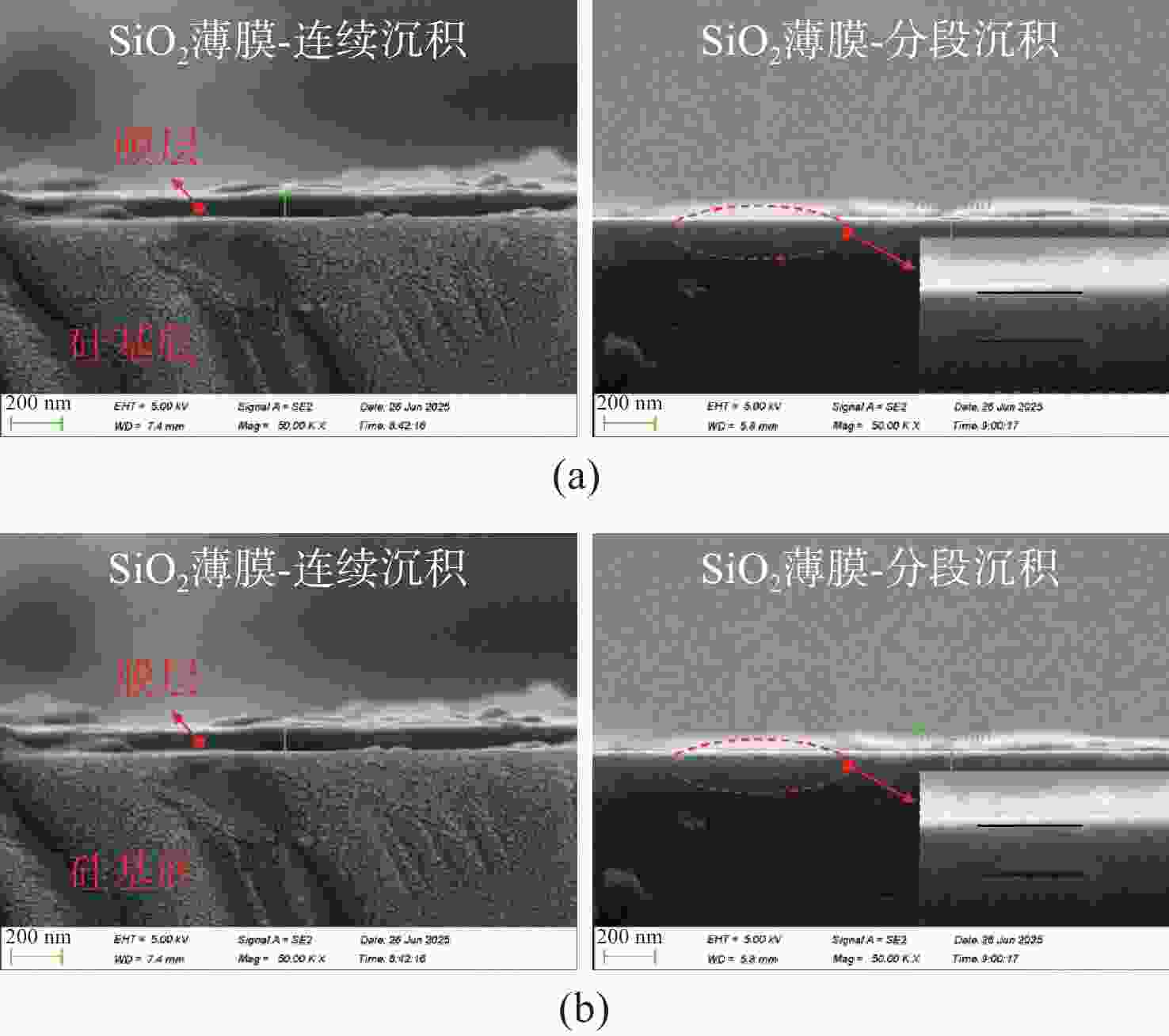

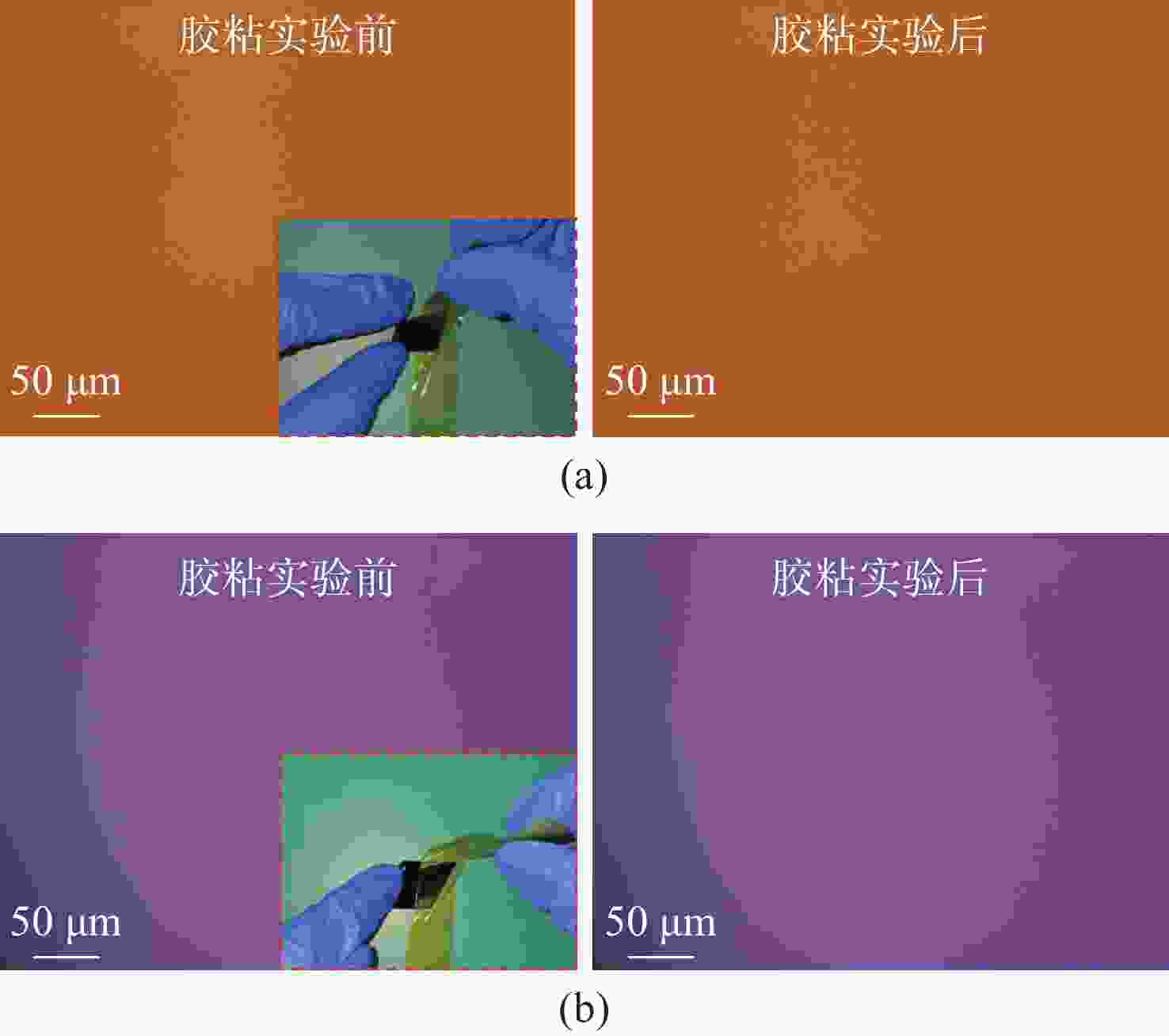

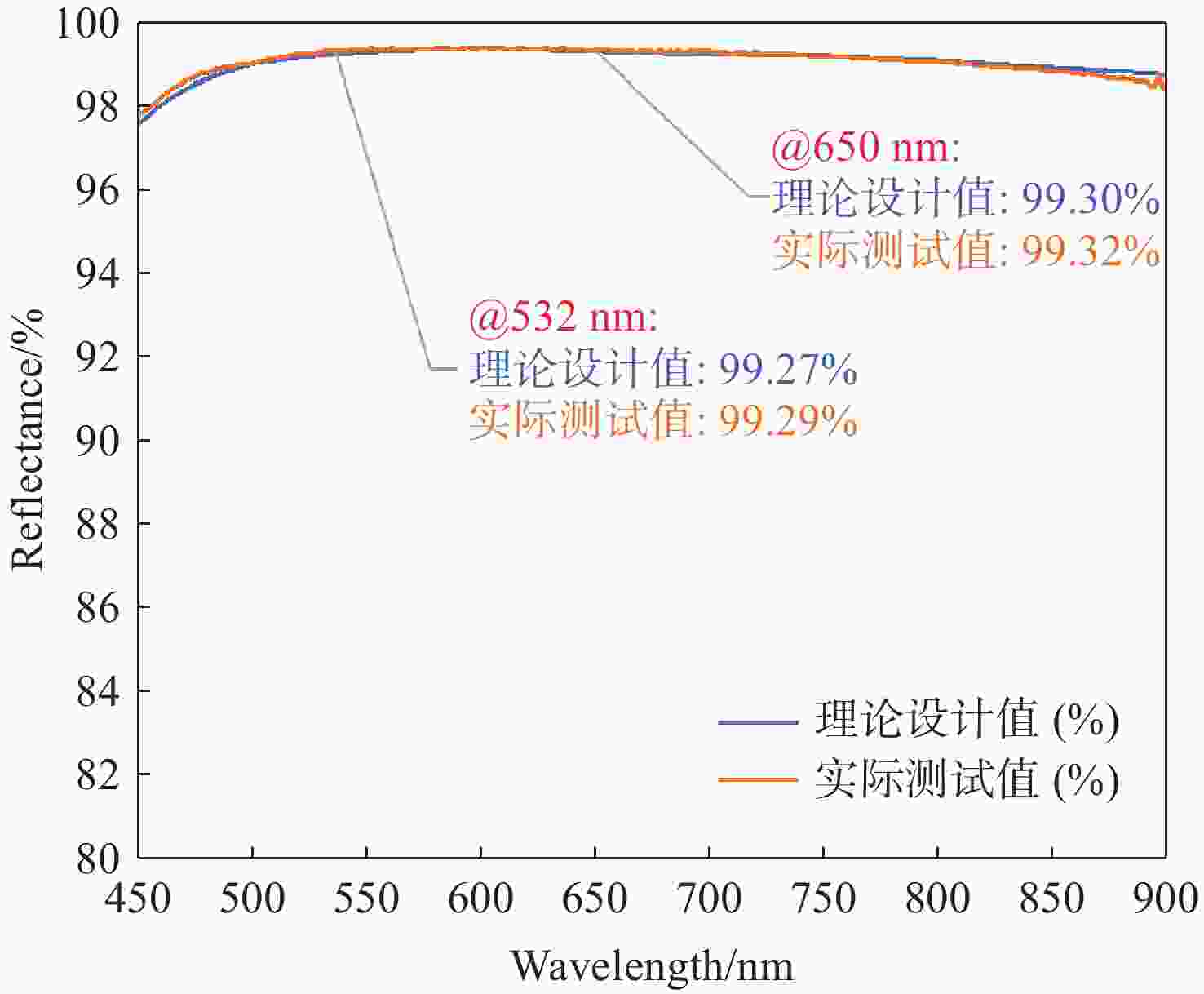

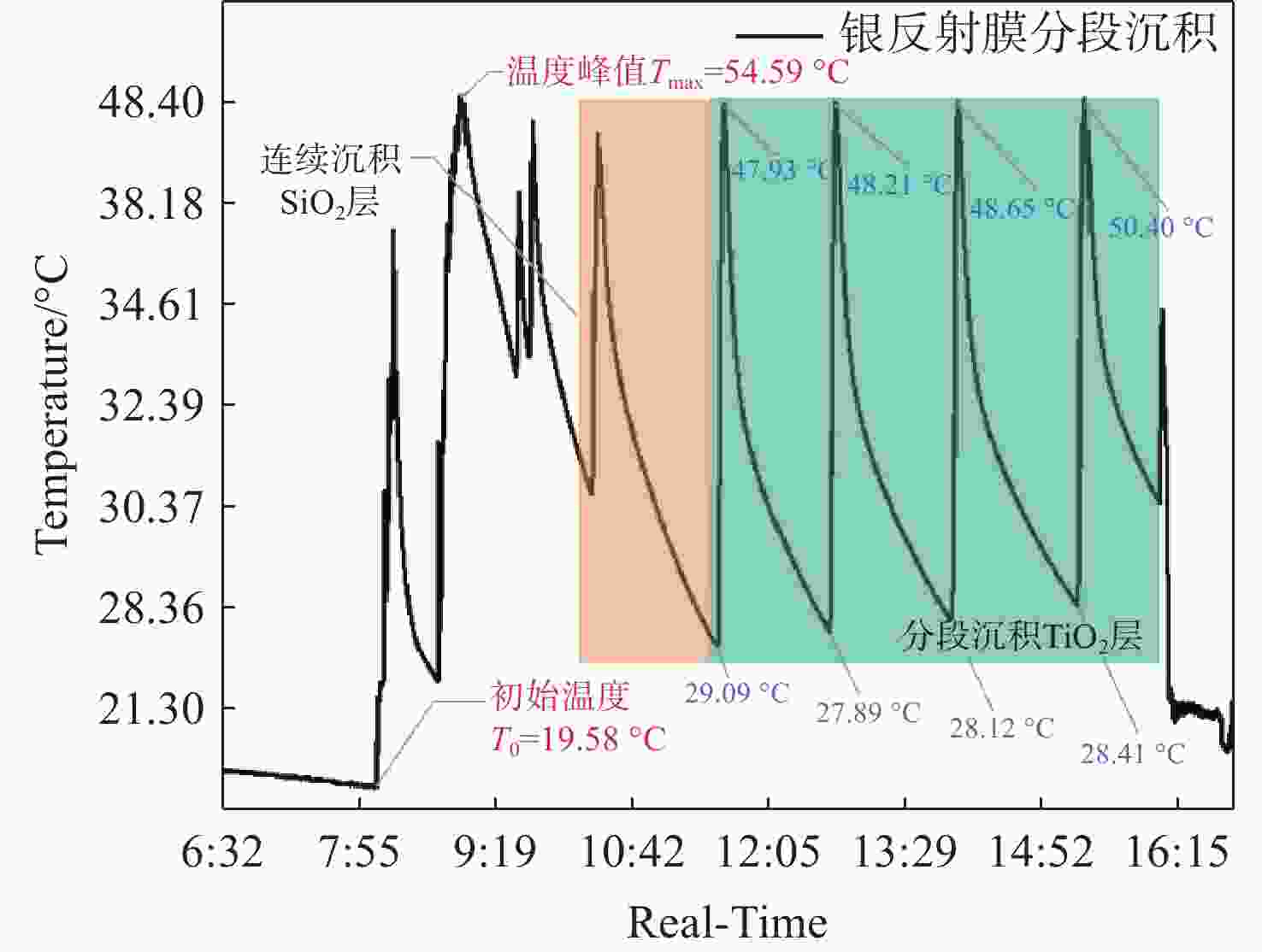

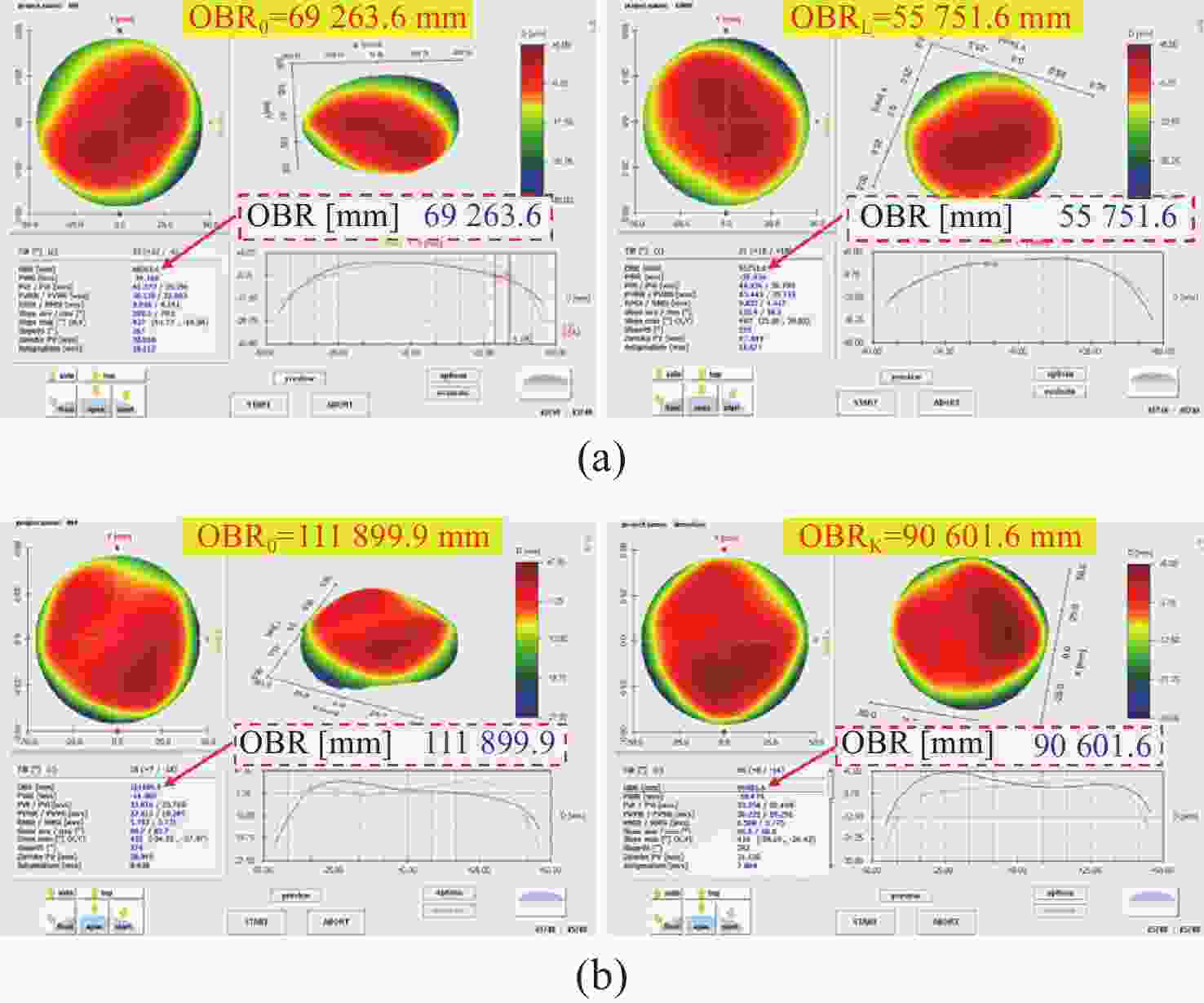

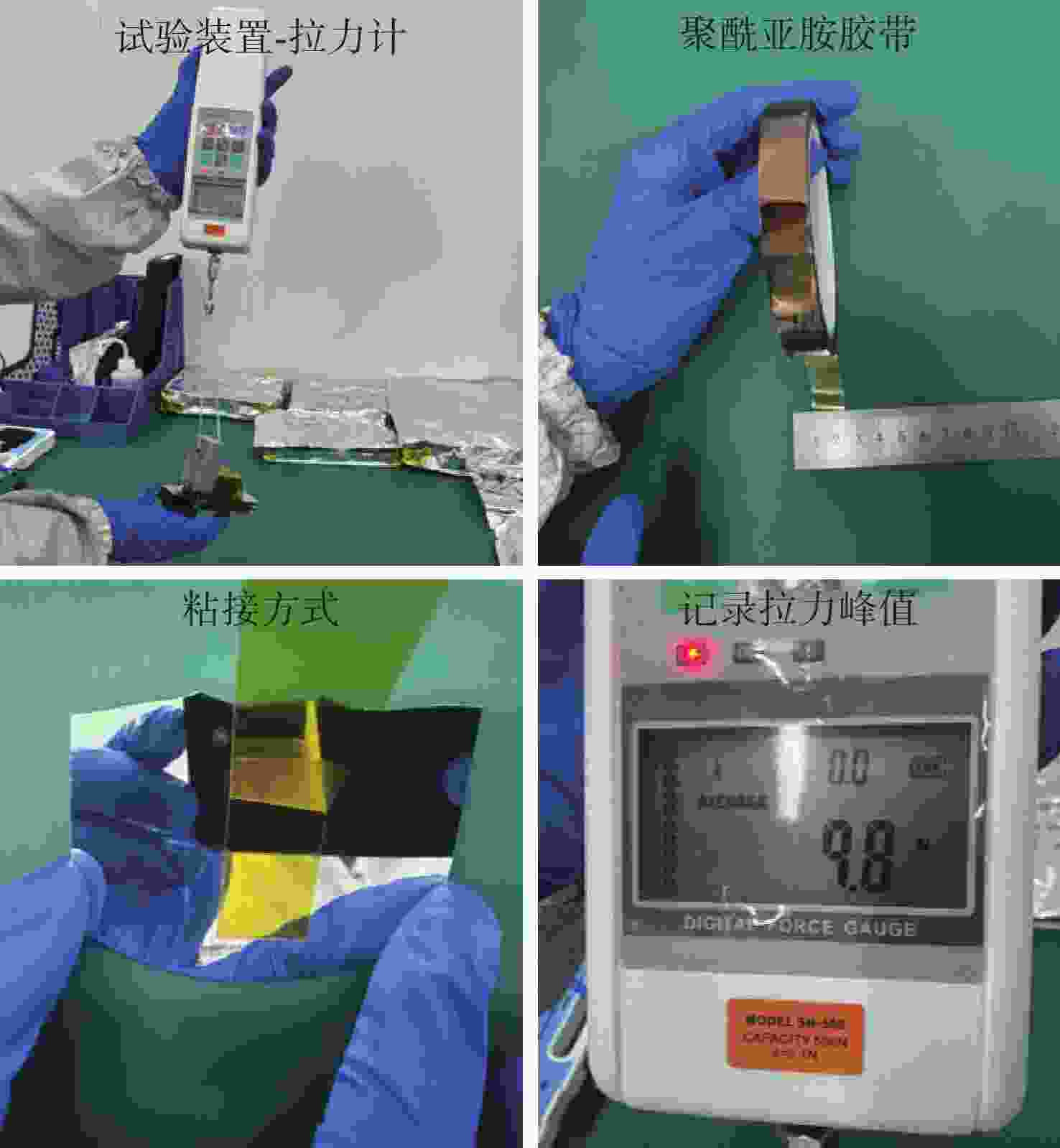

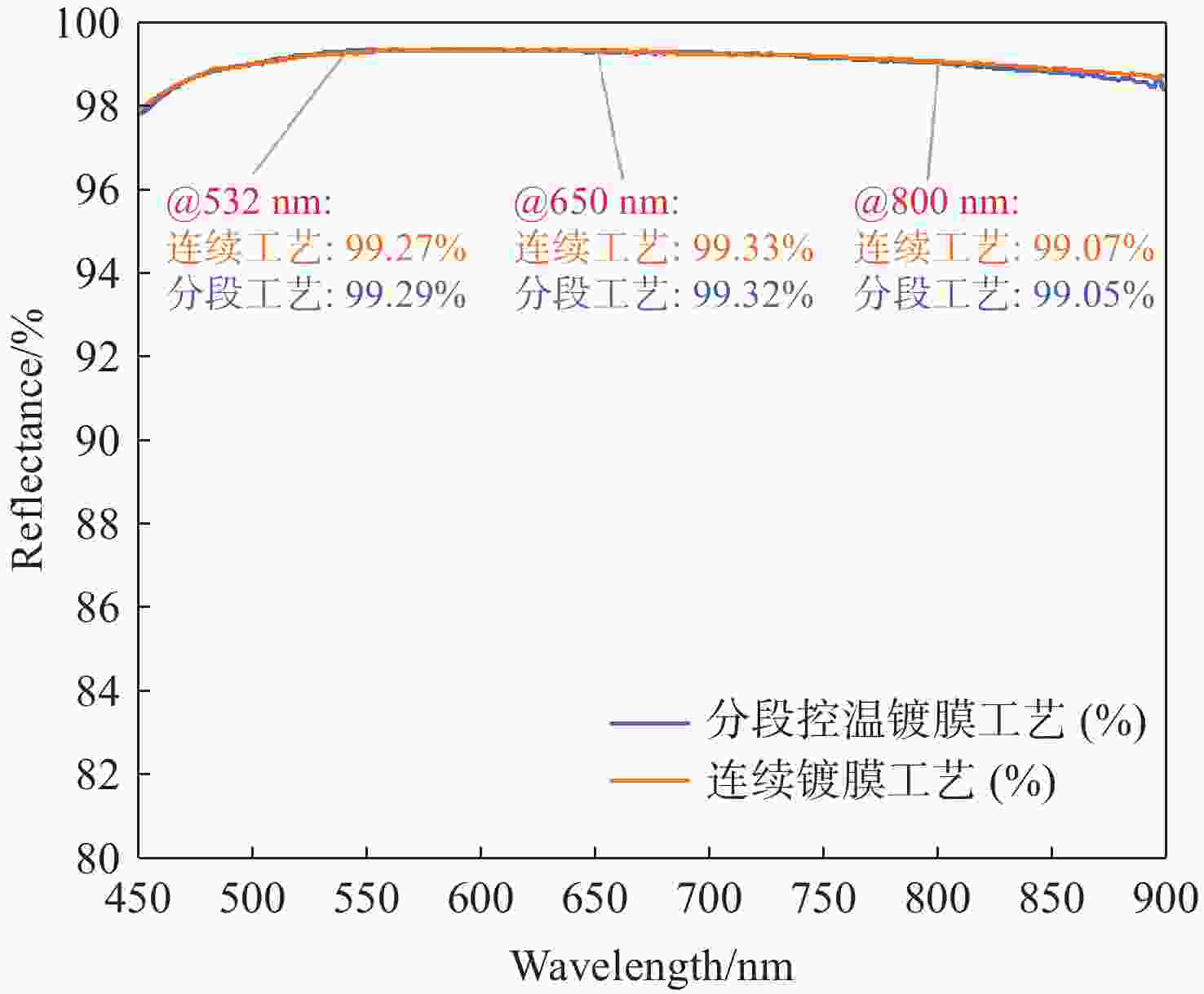

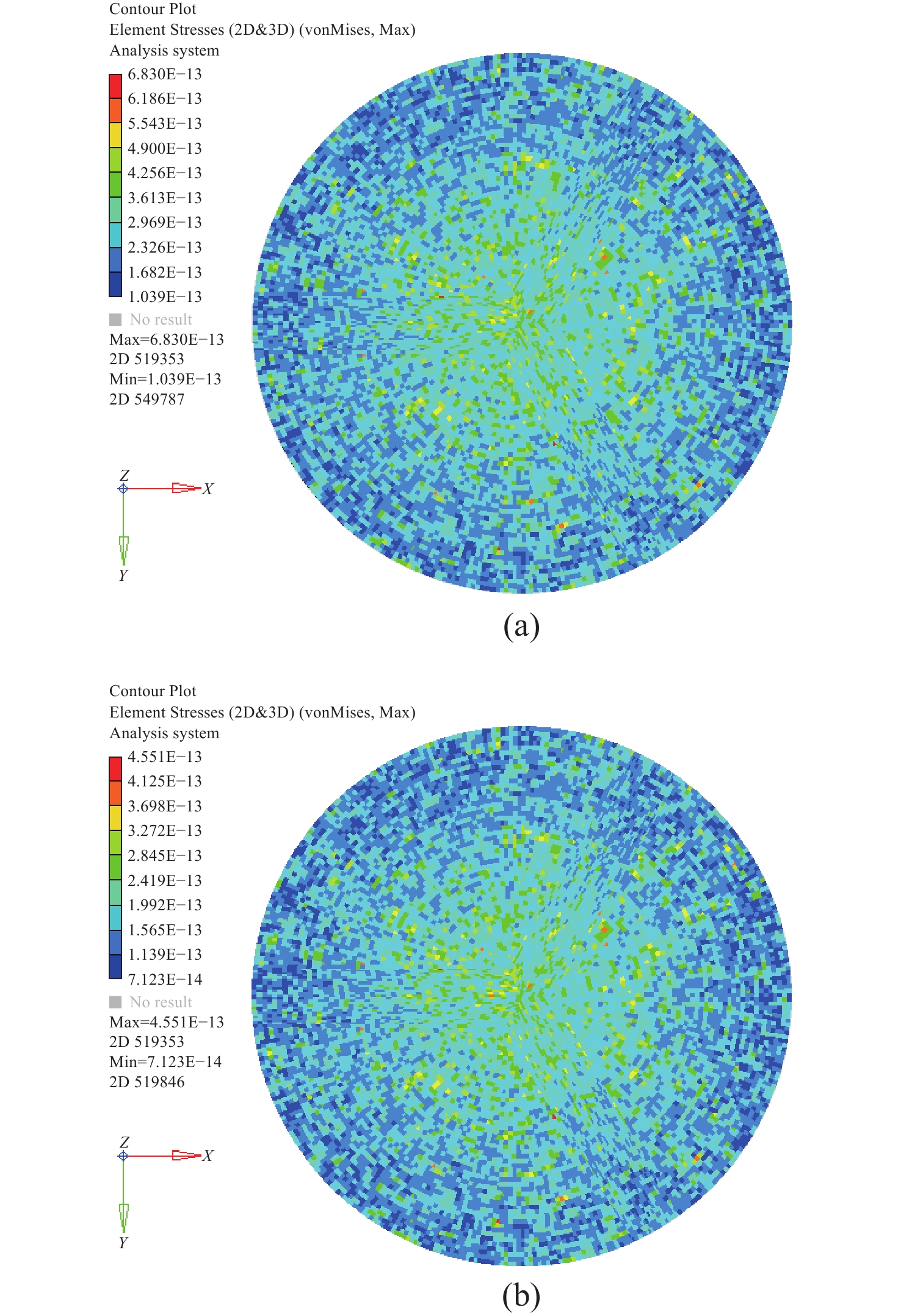

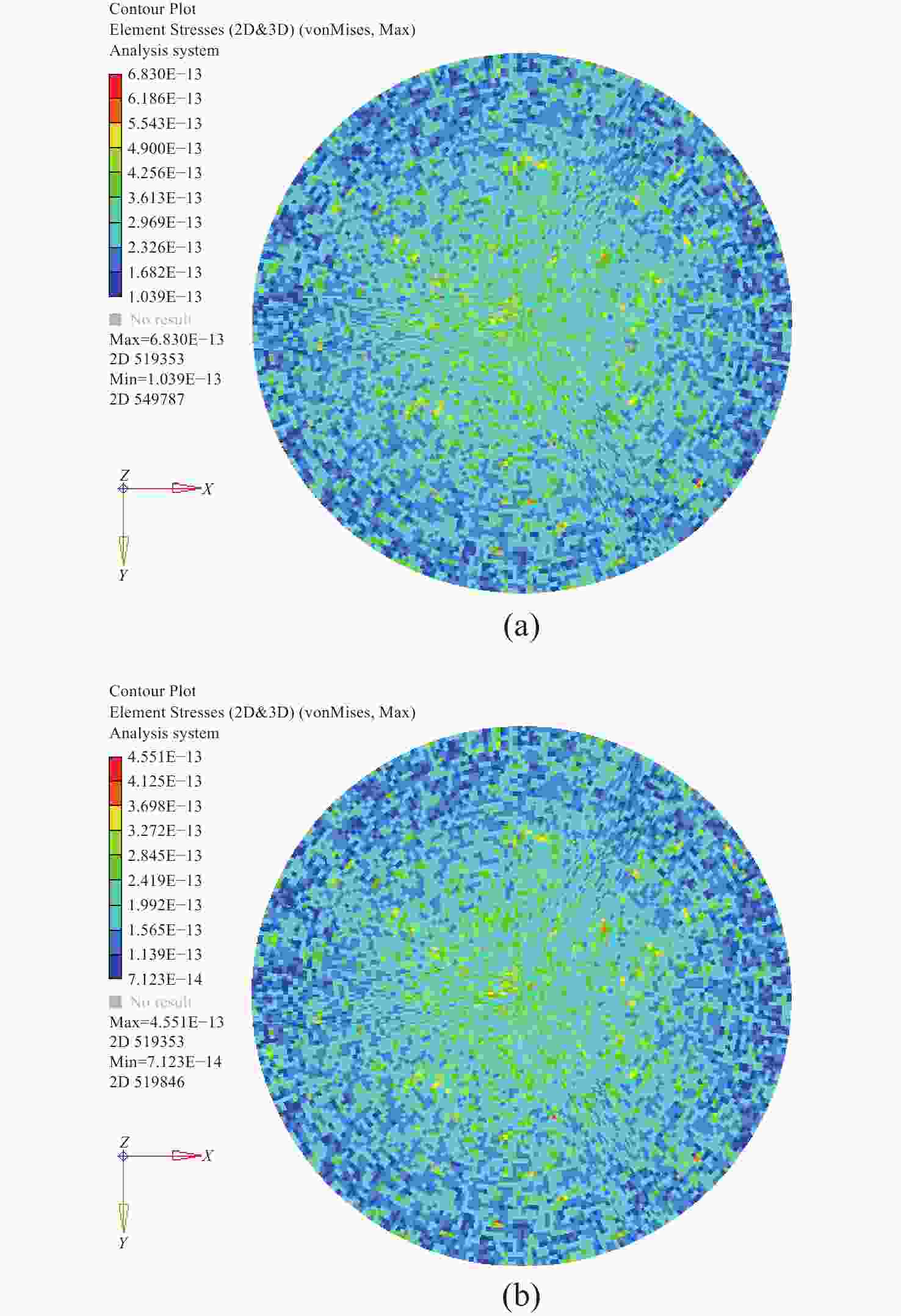

针对热敏感基底(如环氧胶粘接结构件)在镀膜过程中的温升控制难题,本文提出一种低温电子束蒸发镀膜工艺。通过分段沉积-冷却循环的动态热管理策略,系统研究了该工艺在金属反射膜(以银膜为研究对象)的应力、附着力及光学等核心性能方面的表现,并结合环氧胶热失效阈值优化沉积流程。实验结果表明,在基片温度严格受控的条件下,该工艺使得反射膜残余应力显著降低,界面附着力满足国家标准中最严苛的03严酷等级(GB/T

26332.4 -2015/ISO9211 -4:2012),可见光波段平均反射率与传统连续镀膜工艺相当(>99%@450−900 nm),且基片温升始终低于环氧胶临界阈值。通过离子辅助沉积与介质层封装协同作用,银膜抗氧化性与环境耐受性显著提升,满足航天光学器件在极端多物理场耦合环境下的长寿命服役要求。进一步理论分析表明,该工艺的热弛豫机制与结构调控原理具备跨场景适用性,为低温敏感基材的高性能镀膜提供了兼顾航天可靠性及工业普适性的创新解决方案。Abstract:To address the challenge of temperature rise control during the coating process for thermally sensitive substrates (e.g., epoxy adhesive-bonded structural components), this paper proposes a low-temperature electron beam evaporation coating process. Through a dynamic thermal management strategy featuring segmented deposition-cooling cycles, the performance of this process in terms of the core properties (i.e., stress, adhesion, and optical performance) of metallic reflective films-with silver films as the research subject-was systematically investigated, and the deposition process was optimized by integrating the thermal failure threshold of the epoxy adhesive. Experimental results demonstrate that under strictly controlled substrate temperature conditions, this process not only significantly reduces the residual stress of the reflective film, but also ensures that the interfacial adhesion meets the strictest Class 03 severity level specified in the national standard (GB/T 26332.4-2015/ISO 9211-4:2012), the average reflectivity in the visible wavelength range is comparable to that of the traditional continuous coating process (>99%@450−900 nm), and the substrate temperature rise remains consistently below the critical threshold of the epoxy adhesive. Through the synergistic effect of Ion-Assisted Deposition (IAD) and dielectric encapsulation, the oxidation resistance and environmental durability of the silver film are significantly improved, satisfying the long-term service requirements of aerospace optical devices under extreme multi-physics field coupled environments. Further theoretical analysis reveals that the thermal relaxation mechanisms and structural regulation principles of this process exhibit cross-scenario applicability, providing an innovative solution for high-performance coating of low-temperature-sensitive substrates that balances aerospace reliability and industrial universality.

-

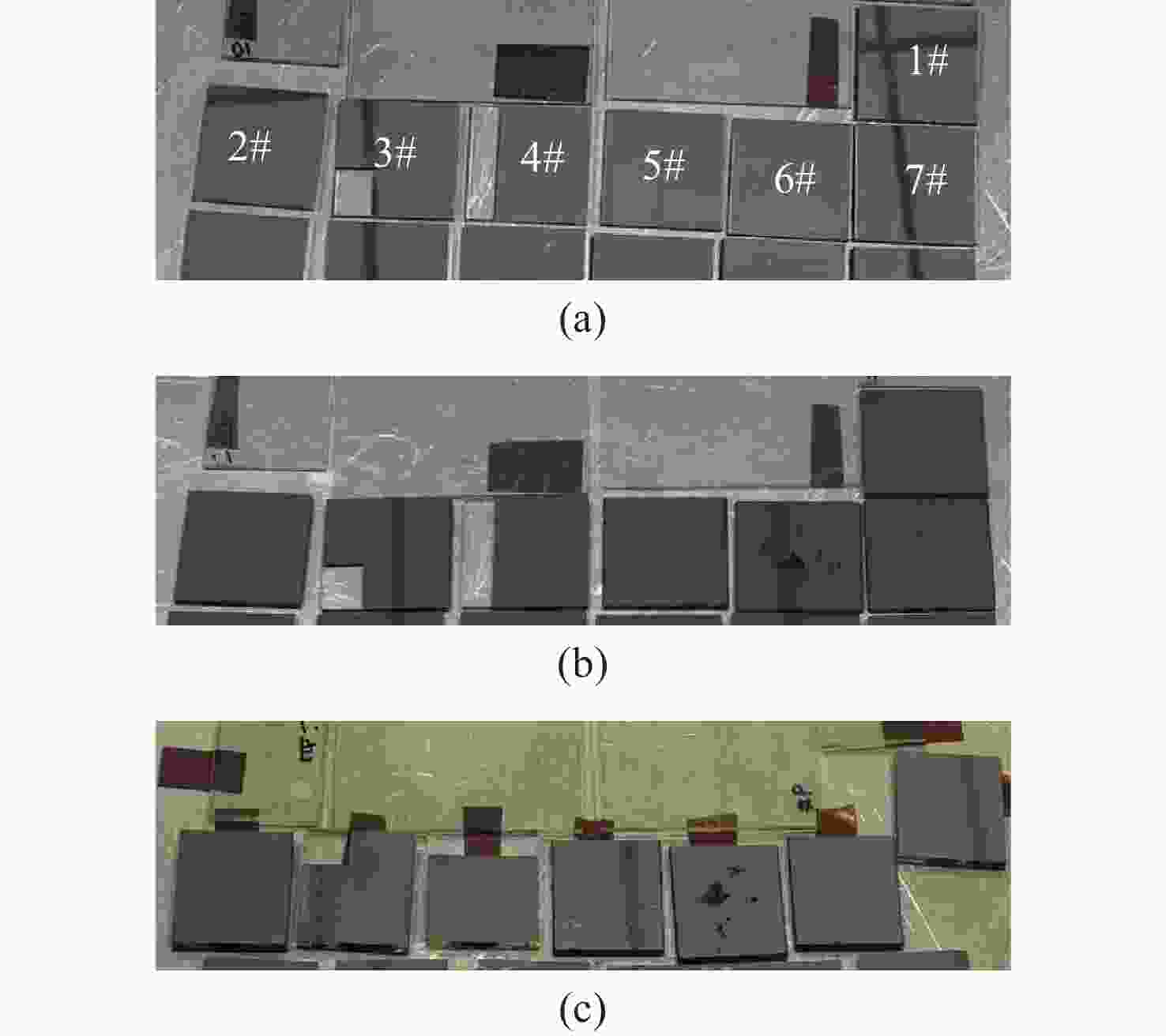

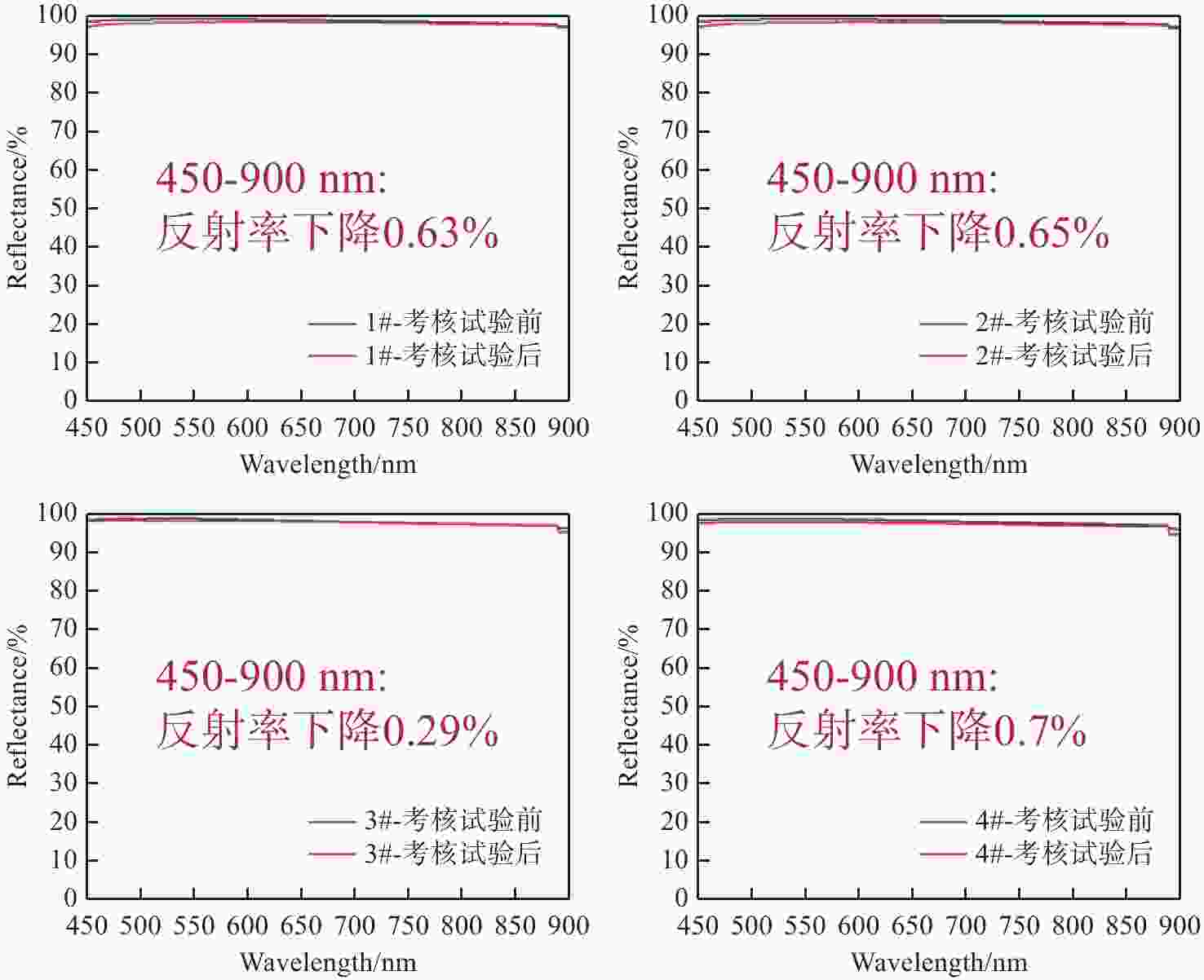

表 1 多物理场耦合环境模拟试验前后光谱变化和膜层情况汇总

Table 1. Summary of spectral changes and film condition before and after the multi-physics coupled environment simulation test

连续镀膜工艺(样品

编号:1#、2#、3#、4#)分段控温镀膜工艺

(样品编号:5#、6#、7#、8#)ΔR̄ 脱膜情况 ΔR̄ 脱膜情况 高低温循环实验 0.11% 否 0.08% 否 振动实验 0.08% 否 0.04% 否 恒定高温试验 0.11% 否 0.10% 否 温湿度试验 0.12% 否 0.12% 否 -

[1] CÔTÉ P, DESNOYERS N. Thermal stress failure criteria for a structural epoxy[J]. Proceedings of the SPIE, 2011, 8125: 81250K. doi: 10.1117/12.893832 [2] https://multimedia.3m.com/mws/media/594118O/3m-scotch-weld-epoxy-adhesive-ec-2216-b-a.pdf?&fn=EC-2216BA.pdf.. [3] 沈凯. 低温冷光学反射镜的支撑技术研究[D]. 长春: 中国科学院大学(中国科学院长春光学精密机械与物理研究所), 2021.SHEN K. Research on support technology of cryogenic optical mirror[D]. Changchun: Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences, 2021. (in Chinese). [4] 李晓雪, 黄玲程, 郝永芹. 离子束辅助电子束蒸镀H4膜工艺及其抗激光损伤特性研究[J]. 激光与光电子学进展, 2022, 59(19): 1931001. doi: 10.3788/LOP202259.1931001LI X X, HUANG L CH, HAO Y Q. Preparing H4 films and their laser damage resistance deposited using ion-beam-assisted electron beam evaporation[J]. Laser & Optoelectronics Progress, 2022, 59(19): 1931001. (in Chinese). doi: 10.3788/LOP202259.1931001 [5] 王英剑, 李庆国, 范正修. 电子束、离子辅助和离子束溅射三种工艺对光学薄膜性能的影响[J]. 强激光与粒子束, 2003, 15(9): 841-844.WANG Y J, LI Q G, FAN ZH X. Property comparison of optical thin films prepared by E-beam, ion assisted deposition and ion beam sputtering[J]. High Power Laser and Particle Beams, 2003, 15(9): 841-844. (in Chinese). [6] 李兆营. 蒸发速率对硅衬底电子束蒸发钛薄膜性能的影响[J]. 电镀与涂饰, 2023, 42(1): 31-34. doi: 10.19289/j.1004-227x.2023.01.006LI ZH Y. Effect of evaporation rate on properties of Ti film prepared by electron beam evaporation on silicon wafer[J]. Electroplating & Finishing, 2023, 42(1): 31-34. (in Chinese). doi: 10.19289/j.1004-227x.2023.01.006 [7] 唐晋发, 顾培夫, 刘旭, 等. 现代光学薄膜技术[M]. 杭州: 浙江大学出版社, 2006.TANG J F, GU P F, LIU X, et al. Modern Optical Thin Film Technology[M]. Hangzhou: Zhejiang University Press, 2006. (in Chinese). [8] 任翼. 真空辅助镀膜离子源的设计及其对沉积膜层影响的研究[D]. 杭州: 中国计量大学, 2024.REN Y. Design of auxiliary ion source for vacuum coating and research of its influence on deposited film[D]. Hangzhou: China Jiliang University, 2024. (in Chinese). [9] 荆建行. 离子束辅助低损耗TiO2光学薄膜研究[D]. 成都: 中国科学院大学(中国科学院光电技术研究所), 2021.JING J X. Study on lon assisted deposition low loss TiO2 optical thin film[D]. Chengdu: The Institute of Optics and Electronics, The Chinese Academy of Sciences, 2021. (in Chinese). [10] 张大伟, 黄元申, 贺洪波, 等. 阶段离子束辅助法制备基频减反膜[J]. 光学 精密工程, 2007, 15(10): 1463-1468. doi: 10.3321/j.issn:1004-924x.2007.10.001ZHANG D W, HUANG Y SH, HE H B, et al. Antireflective film prepared by periodic ion beam assisted deposition[J]. Optics and Precision Engineering, 2007, 15(10): 1463-1468. (in Chinese). doi: 10.3321/j.issn:1004-924x.2007.10.001 [11] 田晓习. 光学薄膜技术中的基片与薄膜热力学匹配问题研究[D]. 成都: 中国科学院大学(中国科学院光电技术研究所), 2020.TIAN X X. Study on thermodynamic matching between substrate and films in optical thin film technology[D]. Chengdu: Institute of Optics and Electronics Chinese Academy of Science, 2020. (in Chinese). [12] 李波, 王超, 闫涛, 等. 多层高反膜的应力研究[J]. 真空与低温, 2023, 29(2): 146-152. doi: 10.3969/j.issn.1006-7086.2023.02.007LI B, WANG CH, YAN T, et al. Stress study of multi-layer high reflection films[J]. Vacuum and Cryogenics, 2023, 29(2): 146-152. (in Chinese). doi: 10.3969/j.issn.1006-7086.2023.02.007 [13] 李阳, 徐均琪, 刘政, 等. 残余应力对介质高反膜面型影响的研究[J]. 真空科学与技术学报, 2021, 41(5): 484-490. doi: 10.13922/j.cnki.cjvst.202009001LI Y, XU J Q, LIU ZH, et al. Study on the influence of residual stress on dielectric high reflection films[J]. Chinese Journal of Vacuum Science and Technology, 2021, 41(5): 484-490. (in Chinese). doi: 10.13922/j.cnki.cjvst.202009001 [14] 樊彦峥. 大口径镜面高反射膜制备及面形控制技术[D]. 西安: 西安工业大学, 2021.FAN Y ZH. Deposition and surface shape control technology of large-aperture mirror high-reflection film[D]. Xian: Xi'an Technological University, 2021. (in Chinese). [15] 王振宇. 利用PEALD/MLD技术实现柔性有机电致发光器件的有机无机杂化薄膜封装[D]. 长春: 吉林大学, 2023.WANG ZH Y. Organic-inorganic hybrid film encapsulation of flexible organic light emitting diodes by PEALD/MLD technology[D]. Changchun: Jilin University, 2023. (in Chinese). [16] WANG ZH Y, CHEN Z Q, WANG J T, et al. Realization of an autonomously controllable process for atomic layer deposition and its encapsulation application in flexible organic light-emitting diodes[J]. Optics Express, 2023, 31(13): 21672-21688. doi: 10.1364/OE.488152 -

下载:

下载: