| [1] |

高强, 尹勇明, 于晶, 等.基于双极传输母体的高效有机磷光发光器件[J].发光学报, 2014, 35(6):717-721. http://d.old.wanfangdata.com.cn/Periodical/fgxb201406015GAO Q, YIN Y M, YU J, et al.. High-efficiency phosphorescent organic light-emitting devices based on bipolar host[J]. Chinese Journal of Luminescence, 2014, 35(6):717-721.(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/fgxb201406015

|

| [2] |

刘健, 谢文法.OLED器件光电性能集成测试系统研制[J].液晶与显示, 2013, 28(1):132-137. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yjyxs201301024LIU J, XIE W F. Integrated optoelectronic performance test system for OLEDs[J]. Chinese Journal of Liquid Crystals and Displays, 2013, 28(1):132-137.(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yjyxs201301024

|

| [3] |

BALDO M A, O'BRIEN D F, YOU Y, et al.. Highly efficient phosphorescent emission from organic electroluminescent devices[J]. Nature, 1998, 395(6698):151-154. doi: 10.1038/25954

|

| [4] |

SASABE H, KIDO J. Development of high performance OLEDs for general lighting[J]. Journal of Materials Chemistry C, 2013, 1(9):1699-1707. doi: 10.1039/c2tc00584k

|

| [5] |

SEKITANI T, NAKAJIMA H, MAEDA H, et al.. Stretchable active-matrix organic light-emitting diode display using printable elastic conductors[J]. Nature Materials, 2009, 8(6):494-499. doi: 10.1038/nmat2459

|

| [6] |

XIONG Y, XU W, LI CH, et al.. Utilizing white OLED for full color reproduction in flat panel display[J]. Organic Electronics, 2008, 9(4):533-538. doi: 10.1016/j.orgel.2008.02.017

|

| [7] |

FAN Y, ZHANG H M, CHEN J SH, et al.. Three-peak top-emitting white organic emitting diodes with wide color gamut for display application[J]. Organic Electronics, 2013, 14(7):1898-1902. doi: 10.1016/j.orgel.2013.04.013

|

| [8] |

LEE S S, SONG T J, CHO S M. Organic white-light-emitting devices based on balanced exciton-recombination-zone split using a carrier blocking layer[J]. Materials Science and Engineering:B, 2002, 95(1):24-28. doi: 10.1016-S0921-5107(02)00087-9/

|

| [9] |

CHEN SH F, WU Q, KONG M, et al.. On the origin of the shift in color in white organic light-emitting diodes[J]. Journal of Materials Chemistry C, 2013, 1(22):3508-3524. doi: 10.1039/c3tc00766a

|

| [10] |

YOON C, KIM T, SHIN M H, et al.. Highly luminescent and stable white light-emitting diodes created by direct incorporation of Cd-free quantum dots in silicone resins using the thiol group[J]. Journal of Materials Chemistry C, 2015, 3(26):6908-6915. doi: 10.1039/C5TC00660K

|

| [11] |

XIANG H F, YU S C, CHE CH M, et al.. Efficient white and red light emission from GaN/tris-(8-hydroxyquinolato) aluminum/platinum(Ⅱ) meso-tetrakis(pentafluorophenyl) porphyrin hybrid light-emitting diodes[J]. Applied Physics Letters, 2003, 83(8):1518-1520. doi: 10.1063/1.1604192

|

| [12] |

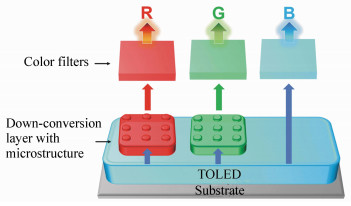

KOH T W, CHO H, YUN CH H, et al.. ITO-free down-conversion white organic light-emitting diodes with structured color conversion layers for enhanced optical efficiency and color rendering[J]. Organic Electronics, 2012, 13(12):3145-3153. doi: 10.1016/j.orgel.2012.09.016

|

| [13] |

LIU SH H, WEN X M, LIU W B, et al.. Angle-stable top-emitting white organic light-emitting devices employing a down-conversion layer[J]. Current Applied Physics, 2014, 14(11):1451-1454. doi: 10.1016/j.cap.2014.08.003

|

| [14] |

JANG E, JUN S, JANG H, et al.. White-light-emitting diodes with quantum dot color converters for display backlights[J]. Advanced Materials, 2010, 22(28):3076-3080. doi: 10.1002/adma.201000525

|

| [15] |

WANG X B, YAN X S, LI W W, et al.. Doped quantum dots for white-light-emitting diodes without reabsorption of multiphase phosphors[J]. Advanced Materials, 2012, 24(20):2742-2747. doi: 10.1002/adma.201104861

|

| [16] |

THOMSCHKE M, REINEKE S, LUSSEM B, et al.. Highly efficient white top-emitting organic light-emitting diodes comprising laminated microlens films[J]. Nano Letters, 2012, 12(1):424-428. doi: 10.1021/nl203743p

|

| [17] |

YANG C J, LIU S H, HSIEH H H, et al.. Microcavity top-emitting organic light-emitting devices integrated with microlens arrays:simultaneous enhancement of quantum efficiency, Cd/A efficiency, color performances, and image resolution[J]. Applied Physics Letters, 2007, 91(25):253508. doi: 10.1063/1.2827182

|

| [18] |

OH J Y, KIM J H, SEO Y K, et al.. Down-conversion light outcoupling films using imprinted microlens arrays for white organic light-emitting diodes[J]. Dyes and Pigments, 2017, 136:92-96. doi: 10.1016/j.dyepig.2016.08.017

|

| [19] |

YIN M J, YU Z W, AN T, et al.. Efficient and angle-stable white top-emitting organic light emitting devices with patterned quantum dots down-conversion films[J]. Organic Electronics, 2018, 56:46-50. doi: 10.1016/j.orgel.2018.02.004

|

下载:

下载: