-

摘要: 中高体积分数SiCp/Al复合材料相较于传统合金材料具有力学性能和热学性能"可裁剪"的特点。本文介绍了中高体积分数SiCp/Al复合材料的主要制备技术工艺,以及中高体积分数SiCp/Al复合材料在精密仪器、光学系统、电子封装及热控领域典型应用,最后展望了中高体积分数SiCp/Al复合材料未来的发展趋势。

-

关键词:

- SiCp/Al复合材料 /

- 中高体积分数 /

- 精密仪器 /

- 光学器件 /

- 电子封装

Abstract: Compared to traditional alloys, medium/high volume fraction SiCp/Al composites offer tailorable mechanical and thermophysical properties that could be beneficial for a variety of applications. In this paper, the main fabrication methods and applications of medium/high volume fraction SiCp/Al composites in precision instruments, optical systems, electronic packaging and thermal control are reviewed and summarized. Finally, the future development strategy of medium/high volume fraction SiCp/Al is proposed. -

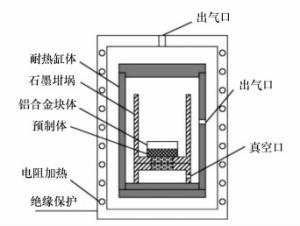

制备技术 成型方式/工艺流程 工艺复杂程度 复杂形状近净尺寸成型 大尺寸预制体制备 制备成本 制备周期 机械化程度 其他特点 粉料堆积成型 采用振动压实的方法获得一定堆积密度的SiC预制体 简单 多为锭坯 是 低 短 较低 可利用预埋型芯可以成型具有一定形状的型腔[15-17] 注射成型 碳化硅+粘结剂混合→注射成型→脱脂→碳化硅预制体[7] 复杂 近净尺寸成型 否 高 长 高 表面光洁度高、预制体尺寸精度高,可制备薄壁预制体[18-20] 模压成型 碳化硅粉体+润滑剂+粘结剂混合→模压成型→烧结→碳化硅预制体 简单 多为锭坯 否 低 较短 高 常见的粘结剂为聚乙烯醇、硅溶胶、磷酸铝等,常见造孔剂为石墨等[21-24] 凝胶注模成型 碳化硅粉体+有机物+分散剂球混→引发剂和催化剂作用下固化凝胶→脱脂→碳化硅预制体 复杂 近净尺寸成型 是 较高 长 低 坯体强度高、有机物含量低、可用于机械加工[25-26] 表 2 粉末冶金法、搅拌铸造法与液相浸渗法工艺比较

Table 2. Comparison of powder metallurgy, stir casting and liquid infiltration methods

制备工艺 优点 缺点 粉末冶金 体积分数可调、材料性能高 工艺复杂、设备成本高 搅拌铸造法 工艺简单,可铸造较为复杂形状制件 增强相体积分数偏低,不易分散均匀 挤压铸造 操作简单、材料性能高、制备时间短 设备成本高、工艺难度较大 气压浸渗 材料性能高,能够制备复杂形状材料 设备要求较高、制备周期较长 无压浸渗 设备要求较低,能够制备大尺寸、复杂形状材料 制备周期较长、易发生有害界面反应 参数 LY12 RJY50 不锈钢 TC4 SiCp/Al(中等体积分数) 密度/(g·cm-3) 2.78 1.85 7.9 4.44 2.9 线膨胀系数/(×10-6K-1) 23 11.8 16.6 9.1 11-13 热导率/(W/(m·K)) 150 >150 16.3 6.8 130~150 弹性模量/GPa 71 309 184 110 140~150 微屈服强度/MPa <120 100 <100 >220 表 4 传统电子封装材料与芯片材料热物理性能与密度[20, 27]

Table 4. Thermophysical properties and density of traditional electric packaging materials and chip materials[20, 27]

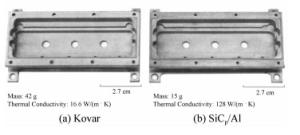

材料 密度/(g·cm-3) 线膨胀系×10-6K-1 热导率W/(m·K) Al 2.7 23.6 238 Cu 8.96 17.8 398 CuW(10~20%Cu) 15.65~17 6.5~8.3 180~200 CuMo(15~20%Mo) 10 7~8 160~170 Invar 8.05 1.6 10 Kovar 8.1 5.2 11~17 SiCp/Al(PRIMEXTM) 3.01 5.8 225 SiCp/Al(CPS) 3 7.63 180 Si 2.3 4.2 151 GaAs 5.32 6.5 54 -

[1] 崔岩.碳化硅颗粒增强铝基复合材料的航空航天应用[J].材料工程, 2002(6):3-6.CUI Y. Aerospace applications of silicon carbide particulate reinforced aluminium matrix composites[J]. Journal of Materials Engineering, 2002(6):3-6.(in Chinese) [2] 曾婧, 彭超群, 王日初, 等.电子封装用金属基复合材料的研究进展[J].中国有色金属学报, 2015, 25(12):3255-3270.ZENG J, PENG CH Q, WANG R CH, et al.. Research and development of metal matrix composites for electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(12):3255-3270.(in Chinese) [3] 吴米贵, 刘君武, 蒋会宾.无压浸渗制备SiCp/Al复合材料的力学性能研究[J].粉末冶金工业, 2014, 24(2):24-28.WU M G, LIU J W, JIANG H B. Study on mechanical properties of SiCp/Al composites prepared by pressureless infiltration[J]. Powder Metallurgy Industry, 2014, 24(2):24-28.(in Chinese) [4] 韩桂泉, 胡喜兰, 李京伟.无压浸渗制备结构/功能一体化铝基复合材料的性能及应用[J].航空制造技术, 2006(1):95-97, 100.HAN G Q, HU X L, LI J W. Property and application of the structure/function integration aluminum matrix composite prepared by pressureless infiltration[J]. Aeronautical Manufacturing Technology, 2006(1):95-97, 100.(in Chinese) [5] 章令晖, 陈萍.复合材料在空间遥感器中的应用进展及关键问题[J].航空学报, 2015, 36(5):1385-1400.ZHANG L H, CHEN P. Application progress of composites in space remote sensor and its key problems[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(5):1385-1400.(in Chinese) [6] 李佳双, 屈敏, 崔岩, 等.Si、Mg含量对Al-Mg-Si合金显微组织及显微硬度的影响[J].金属热处理, 2016, 41(12):69-74.LI J SH, QU M, CUI Y, et al.. Effect of Si, Mg content on microstructure and microhardness of Al-Mg-Si alloy[J]. Heat Treatment of Metals, 2016, 41(12):69-74.(in Chinese) [7] 崔葵馨, 常兴华, 李希鹏, 等.高体积分数铝碳化硅复合材料研究进展[J].材料导报, 2012, 26(S2):401-405.CUI K X, CHANG X H, LI X P, et al.. Advances in research on high volume fraction aluminum silicon carbide composites[J]. Materials Review, 2012, 26(S2):401-405.(in Chinese) [8] 刘冀念, 董蓉桦, 刘炎, 等.高体积分数SiCp/7075Al复合材料的时效析出行为[J].材料科学与工程学报, 2016, 34(3):357-361.LIU J N, DONG R H, LIN Y, et al.. Aging behavior of high volume fraction SiCp/7075Al composites[J]. Journal of Materials Science and Engineering, 2016, 34(3):357-361.(in Chinese) [9] 金鹏, 刘越, 李曙, 等.颗粒增强铝基复合材料在航空航天领域的应用[J].材料导报, 2009, 23(11):24-27, 39.JIN P, LIU Y, LI SH, et al.. Aerospace applications of particulate reinforced aluminum matrix composites[J]. Materials Review, 2009, 23(11):24-27, 39.(in Chinese) [10] 钟鼓, 吴树森, 万里.高SiCp或高Si含量电子封装材料研究进展[J].材料导报, 2008, 22(2):13-17.ZHONG G, WU SH S, WAN L. Research development of electronic packaging materials with high SiCp or Si content[J]. Materials Review, 2008, 22(2):13-17.(in Chinese) [11] 张晓辉, 王强.电子封装用金属基复合材料的研究现状[J].微纳电子技术, 2018, 55(1):18-25, 44.ZHANG X H, WANG Q. Research state of metal-matrix composites for electronic packaging[J]. Micronanoelectronic Technology, 2018, 55(1):18-25, 44.(in Chinese) [12] MAO X ZH, HONG Y, WANG B H, et al.. Fabrication, microstructures and properties of 50 vol.-% SiCp/6061Al composites via a pressureless sintering technique[J]. Powder Metallurgy, 2017, 61(1):1-9. [13] 王治国.纳米SiC增强铝基复合材料的粉末冶金法制备及其力学性能[D].长春: 吉林大学, 2016.WANG ZH G. Fabrication and mechanical properties of nano-SiC reinforced aluminum matrix composites by powder metallurgy method[D]. Changchun: Jilin University, 2016.(in Chinese) [14] 崔葵馨.高体积分数铝碳化硅复合材料中试工艺研究[D].长沙: 中南大学, 2013.CUI K X. Pilot-scale study on high volume fraction AlSiC composite[D]. Changsha: Central South University, 2013.(in Chinese) [15] 崔岩, 郭顺, 赵会友.高体份SiCp/Al复合材料型芯法无压浸渗近净成形制备技术[J].航空材料学报, 2010, 30(6):51-56.CUI Y, GUO SH, ZHAO H Y. Near net-shape forming technique with mold core of high volume fraction SiCp/Al composite in pressureless infiltration process[J]. Journal of Aeronautical Materials, 2010, 30(6):51-56.(in Chinese) [16] 崔岩.一种高体份颗粒增强金属基复合材料的近净形制备方法: 中国, CN102009160A[P].2011-04-13.CUI Y. A net-shape preparation method for high volume particulate reinforced metal matrix composites: CN, CN102009160A[P]. 2011-04-13.(in Chinese) [17] 崔岩, 张洪立.一种高体份颗粒增强金属基复合材料管材的制造方法: 中国, CN101423904A[P].2009-05-06.CUI Y, ZHANG H L. Manufacturing method of high volume particle reinforced metal matrix composite pipe: CN, CN101423904A[P].2009-05-06.(in Chinese) [18] FANG W, HE X B, ZHANG R J, et al.. Evolution of stresses in metal injection molding parts during sintering[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(2):552-558. [19] 熊德赣, 程辉, 刘希从, 等.AlSiC电子封装材料及构件研究进展[J].材料导报, 2006, 20(3):111-115.XIONG D G, CHENG H, LIU X C, et al.. Advances in research on aluminum silicon carbide electronic packaging composites and components[J]. Materials Review, 2006, 20(3):111-115.(in Chinese) [20] OCCHIONERO M A, HAY R A, ADAMS R W, et al.. Aluminum silicon carbide(AlSiC) for cost-effective thermal management and functional microelectronic packaging design solutions[EB/OL]. http://pdfs.semanticscholar.org/c900/26f270a8d8278db3fa1bfc68875683addedb.pdf. [21] 张强, 姜龙涛, 武高辉.无压浸渗法制备氧化态SiC颗粒增强铝基复合材料[J].无机材料学报, 2012, 27(4):353-357.ZHANG Q, JIANG L T, WU G H. Fabrication of oxidized SiC particles reinforced aluminum matrix composite by pressureless infiltration technique[J]. Journal of Inorganic Materials, 2012, 27(4):353-357.(in Chinese) [22] 梁建芳.无压浸渗制备Al/SiCp电子封装材料的结构与性能[D].西安: 西北工业大学, 2006.LIANG J F. The structure and properties of Al/SiCp composites preparated by pressureless infiltration for electronic packaging[D]. Xi'an: Northwestern Polytechnical University, 2006.(in Chinese) [23] 刘媛媛.无压浸渗法制备β-SiCp/Al电子封装材料工艺与性能研究[D].西安: 西安科技大学, 2008.LIU Y Y. Fabrication and properties of β-SiCp/Al electronic packaging material by pressureless infiltration[D]. Xi'an: Xi'an University of Science and Technology, 2008.(in Chinese) [24] 熊德赣, 杨盛良, 白书欣, 等.带金属密封环的AlSiC管壳制备与性能[J].电子与封装, 2008, 8(3):14-17, 21.XIONG D G, YANG SH L, BAI SH X, et al.. Fabrication and property of aluminum silicon carbide packaging housing with metal seal ring[J]. Electronics & Packaging, 2008, 8(3):14-17, 21.(in Chinese) [25] 王小锋, 王日初, 彭超群, 等.凝胶注模成型技术的研究与进展[J].中国有色金属学报, 2010, 20(3):496-509.WANG X F, WANG R CH, PENG CH Q, et al.. Research and development of gelcasting[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3):496-509.(in Chinese) [26] 赵文兴, 张舸, 赵汝成, 等.轻型碳化硅质反射镜坯体的制造工艺[J].光学 精密工程, 2011, 19(11):2609-2617.ZHAO W X, ZHANG G, ZHAO R CH, et al.. Fabrication of silicon carbide lightweight mirror blank[J]. Opt. Precision Eng., 2011, 19(11):2609-2617.(in Chinese) [27] 武高辉.金属基复合材料设计引论[M].北京:科学出版社, 2016:42-57.WU G H. Introduction of Metal Matrix Composite Design[M]. Beijing:Science Press, 2016:42-57.(in Chinese) [28] 修子扬, 张强, 王子鸣, 等.电子封装用SiCp/6063复合材料的制备与性能研究[J].精密成形工程, 2018, 10(1):91-96.XIU Z Y, ZHANG Q, WANG Z M, et al.. Preparation and properties of SiCp/6063 composites for electronic packaging[J]. Journal of Netshape Forming Engineering, 2018, 10(1):91-96.(in Chinese) [29] 谢斌, 王晓刚, 华小虎, 等.底部真空负压浸渗工艺制备β-SiCp/Al电子封装材料[J].铸造, 2013, 62(10):953-957.XIE B, WANG X G, HUA X H, et al.. β-SiCp/Al composites for electronic packaging prepared by the process of bottom-vacuum negative pressure infiltration[J]. Foundry, 2013, 62(10):953-957.(in Chinese) [30] 崔岩, 李丽富, 李景林, 等.制备空间光机结构件的高体份SiC/Al复合材料[J].光学 精密工程, 2007, 5(8):1175-1180.CUI Y, LI L F, LI J L, et al.. High volume fraction SiC/Al composites for space-based optomechanical structures[J]. Opt. Precision Eng., 2007, 5(8):1175-1180.(in Chinese) [31] AGHAJANIAN M K, ROCAZELLA M A, BURKE J T, et al.. The fabrication of metal matrix composites by a pressureless infiltration technique[J]. Journal of Materials Science, 1991, 26(2):447-454. [32] CUI Y, GAN S M, LIU F B, et al.. Analysis of porosity in high volume fraction SiCp/Al composites fabricated by pressureless infiltration[J]. Materials Research Innovations, 2015, 19(S9):S9-116-S9-122. [33] XIE B, WANG X G. Thermo-physical properties and reaction process of SiCp/Al-7Si-5Mg aluminum matrix composites fabricated by pressureless infiltration[J]. Rare Metal Materials and Engineering, 2015, 44(5):1057-1061. [34] KARANDIKAR P G, AGHAJANIAN M K, AGRAWAL D, et al.. Microwave assisted (Mass) processing of metal-ceramic and reaction-bonded composites[M]. Hoboken, NJ:Wiley, 2006:435-446. [35] 王武杰, 洪雨, 吴玉程.SiC粒径比及体积比对SiCp/Al-5Si-2.5Mg复合材料组织及性能影响[J].材料热处理学报, 2018, 39(7):7-14.WANG W J, HONG Y, WU Y CH. Effect of SiC particle size ratio and volume fraction ratio on microstructure and properties of SiCp/Al-5Si-2.5Mg composites[J]. Transactions of Materials and Heat Treatment, 2018, 39(7):7-14.(in Chinese) [36] 顾晓峰, 张联盟, 杨梅君, 等.SiCp/Al复合材料的SPS烧结及热物理性能研究[J].无机材料学报, 2006, 21(6):1405-1410.GU X F, ZHANG L M, YANG M J, et al.. Fabrication and thermophysical properties of SiCp/Al metal-matrix composites by SPS[J]. Journal of Inorganic Materials, 2006, 21(6):1405-1410.(in Chinese) [37] 刘兴丹, 阎峰云, 赵红娟, 等.烧结温度对SiCp/Al复合材料组织与性能的影响[J].粉末冶金材料科学与工程, 2017, 22(1):20-25.LIU X D, YAN F Y, ZHAO H J, et al.. Effect of sintering temperatrue on microstructure and properties of SiCp/Al composites[J]. Materials Science and Engineering of Powder Metallurgy, 2017, 22(1):20-25.(in Chinese) [38] 武高辉, 姜龙涛, 陈国钦, 等.仪表级复合材料在惯性仪表中的应用进展[J].导航定位与授时, 2014, 1(1):63-68.WU G H, JIANG L T, CHEN G Q, et al.. Application progress of instrument grade Al matrix composites in inertial instruments[J]. Navigation Positioning & Timing, 2014, 1(1):63-68.(in Chinese) [39] MOHN W R, VUKOBRATOVICH D. Recent applications of metal matrix composites in precision instruments and optical systems[J]. Journal of Materials Engineering, 1988, 10(3):225-235. [40] 聂俊辉, 樊建中, 魏少华, 等.航空用粉末冶金颗粒增强铝基复合材料研制及应用[J].航空制造技术, 2017(16):26-36.NIE J H, FAN J ZH, WEI SH H, et al.. Research and application of powder metallurgy particle reinforced aluminum matrix composite used in naviation[J]. Aeronautical Manufacturing Technology, 2017(16):26-36.(in Chinese) [41] 许小静, 张绪虎, 王亮, 等.中低体积分数SiCp/Al在航空航天领域的应用与发展[J].宇航材料工艺, 2011, 41(3):5-7.XU X J, ZHANG X H, WANG L, et al.. Development and application of medium/low volume-fraction SiCp/Al composites in aerospace field[J]. Aerospace Materials & Technology, 2011, 41(3):5-7.(in Chinese) [42] 齐光, 王书新, 李景林.空间遥感器高体分SiC/Al复合材料反射镜组件设计[J].中国光学, 2015, 8(1):99-106.QI G, WANG SH X, LI J L. Design of high volume fraction SiC/Al composite mirror in space remote sensor[J]. Chinese Optics, 2015, 8(1):99-106.(in Chinese) [43] 田富湘, 何欣.基于高体分SiCp/Al材料的空间相机主支撑结构研制[J].红外, 2015, 36(11):36-40.TIAN F X, HE X. Development of welded space camera supporting structure based on high volume SiCp/Al composites[J]. Infrared, 2015, 36(11):36-40.(in Chinese) [44] MOHN W R, VUKOBRATOVICH D. Engineered metal matrix composites for precision optical systems[J]. SAMPE Journal, 1988, 24(1):26-35. [45] GEIGER A L, SR E U. Production of metal matrix composite mirrors for tank fire control systems[J]. Proceedings of SPIE, 1992, 1690:232-243. [46] JIANG X X, LAURIN D G, LEVESQUE D, et al.. Design and fabrication of a lightweight laser scanning mirror from metal-matrix composites[J]. Proceedings of SPIE, 2001, 4444:1-8. [47] 程志峰, 张葆, 崔岩, 等.高体份SiC/Al复合材料在无人机载光电稳定平台中的应用[J].光学 精密工程, 2009, 17(11):2820-2827.CHENG ZH F, ZHANG B, CUI Y, et al.. Application of high volume fraction SiC/Al composites to unmanned airborne photoelectric platforms[J]. Opt. Precision Eng., 2009, 17(11):2820-2827.(in Chinese) [48] 李畅, 何欣, 刘强.高体份SiC/Al复合材料空间相机框架的拓扑优化设计[J].红外与激光工程, 2014, 43(8):2526-2531.LI CH, HE X, LIU Q. Design and topology optimization of space camera frame fabricated by high volume fraction SiC/Al composite material[J]. Infrared and Laser Engineering, 2014, 43(8):2526-2531.(in Chinese) [49] LOU H S, QU S G, WANG B, et al, . Glass coating on SiCp/Al composite mirror for ultra-smooth surface[J]. International Journal of Advanced Manufacturing Technology, 2017, 88(2):1745-1753. [50] ZWEBEN C. Metal-matrix composites for electronic packaging[J]. JOM, 1992, 44(7):15-23. [51] RAWAL S P. Metal-matrix composites for space applications[J]. JOM, 2001, 53(4):14-17. [52] OCCHIONERO M A, HAY R A, ADAMS R W, et al. Aluminum silicon carbide(AlSiC) thermal management packaging for high density packaging applications[C]. Proceedings of SPIE-The International Society for Optical Engineering, 1999. [53] 谢大鹏, 崔葵馨, 金胜明.IGBT用AlSiC复合材料的制备研究[J].佛山陶瓷, 2018, 28(2):14-18.XIE D P, CUI K X, JIN SH M. Preparation of AlSiC composite for IGBT[J]. Foshan Ceramics, 2018, 28(2):14-18.(in Chinese) [54] 何新波, 任淑彬, 曲选辉, 等.电子封装用高导热金属基复合材料的研究[J].真空电子技术, 2010(4):1-4.HE X B, REN SH B, QU X H, et al.. Preparation of high thermal conductivity metal matrix composites for electronic packaging[J]. Vacuum Electronics, 2010(4):1-4.(in Chinese) [55] 吴金方, 刘君武, 丁锋, 等.AlSiC电子封装材料的凝胶注模法制备[J].合肥工业大学学报(自然科学版), 2011, 34(3):336-340.WU J F, LIU J W, DING F, et al.. Preparation of AlSiC electronic package materials by gel-casting[J]. Journal of Hefei University of Technology(Natural Science), 2011, 34(3):336-340.(in Chinese) [56] 熊德赣, 刘希从, 堵永国, 等.小批量铝碳化硅T/R组件封装外壳的研制[J].电子与封装, 2004, 4(4):29-32.XIONG D G, LIU X C, DU Y G, et al.. The research of a small amount AlSiC packaging housing of T/R module[J]. Electronics & Packaging, 2004, 4(4):29-32.(in Chinese) -

下载:

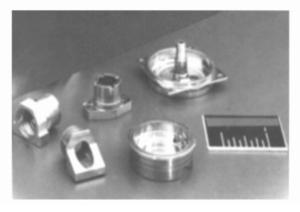

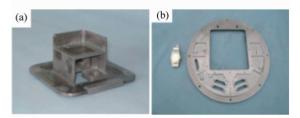

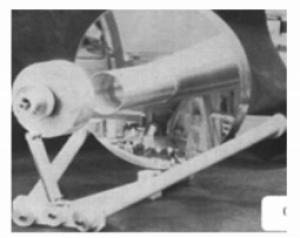

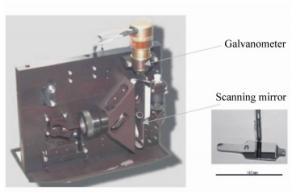

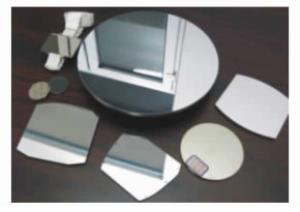

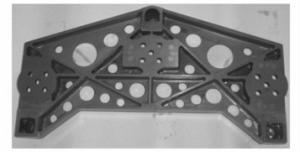

下载: