| [1] |

HARRISON G R. The production of diffraction gratings:Ⅱ.the design of echelle gratings and spectrographs[J]. J. Optical Society of America,1949,39(7):522-528. doi: 10.1364/JOSA.39.000522

|

| [2] |

SONG J,CHEN L,LI B. A fast simulation method of silicon nanophotonic echelle gratings and its applications in the design of on-chip spectrometers[J]. Progress In Electromagnetics Research,2013,141:369-382. doi: 10.2528/PIER13052801

|

| [3] |

BACH K G,BACH Jr B W. Large-ruled monolithic echelle gratings[J]. SPIE,2000,4014:118-124. http://cn.bing.com/academic/profile?id=2165514784&encoded=0&v=paper_preview&mkt=zh-cn

|

| [4] |

张方程,于海利,周敬萱.大尺寸中阶梯光栅铝膜均匀性研究[J].长春工业大学学报:自然科学版,2013,34(2):195-199. http://www.cnki.com.cn/Article/CJFDTOTAL-JLGX201302015.htmZHANG F CH,YU H L,ZHOU J X. Uniformity of large size echelle grating substrate film[J]. J. Changchun University of Technology(Natural Science Edition),2013,34(2):195-199.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-JLGX201302015.htm

|

| [5] |

ENGMAN S,LINDBLOM P. Blaze characteristics of echelle gratings[J]. Applied Optics,1982,21(23):4356-4362. doi: 10.1364/AO.21.004356

|

| [6] |

LINDBLOM P. Echelle gratings acting as one[J]. Applied Optics,2003,42(22):4549-4559. doi: 10.1364/AO.42.004549

|

| [7] |

朱文煜,陈少杰,撖芃芃,等.分波段式中阶梯光栅原子发射光谱仪[J].光学精密工程,2014,22(4):870-876. doi: 10.3788/OPE.ZHU W Y,CHEN SH J,HAN P P,et al.. Echelle-emission spectrometer with divided spectral coverage[J]. Opt. Precision Eng.,2014,22(4):870-876.(in Chinese) doi: 10.3788/OPE.

|

| [8] |

唐玉国,宋楠,巴音,等.中阶梯光栅光谱仪的光学设计[J].光学精密工程,2010,18(9):1989. http://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201009013.htmTANG Y G,SONG N,BA Y,et al.. Optical design of cross-dispersed spectrograph[J]. Opt. Precision Eng.,2010,18(9):1989.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201009013.htm

|

| [9] |

唐玉国,陈少杰,巴音,等.中阶梯光栅光谱仪的谱图还原与波长标定[J].光学精密工程,2010,18(10):2130-2135. http://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201010003.htmTANG Y G,CHEN SH J,BA Y,et al.. Spectral reducing of cross-dispersed echelle spectrograph and its wavelength calibration[J]. Opt. Precision Eng.,2010,18(10):2130-2135.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201010003.htm

|

| [10] |

BAMARD T W,CROCKETT M I,IVALDI J C,et al.. Design and evaluation of an echelle grating optical system for ICP-OES[J]. Analytical Chemistry,1993,65(9):1225-1230. doi: 10.1021/ac00057a020

|

| [11] |

NEVEJANS D,NEEFS E,VAN RANSBEECK E,et al.. Compact high-resolution spaceborne echelle grating spectrometer with acousto-optical tunable filter based order sorting for the infrared domain from 2.2 to 4.3μm[J]. Applied Optics,2006,45(21):5191-5206. doi: 10.1364/AO.45.005191

|

| [12] |

HARRISON G R,THOMPSON S W,KAZUKONIS H,et al.. 750-mm ruling engine producing large gratings and echelles[J]. JOSA,1972,62(6):751-756. doi: 10.1364/JOSA.62.000751

|

| [13] |

李资政,杨海贵,王笑夷,等.具有大面积均匀性,高质量的大尺寸中阶梯光栅铝膜的研究[J].物理学报,2014,63(15):157801-157801. http://www.cnki.com.cn/Article/CJFDTOTAL-WLXB201415056.htmLI Z ZH,YANG H G,WANG X Y,et al.. Investigations of high-quality aluminum film with large-area uniformity for large-size echelle grating[J]. Acta Phys. Sin.,2014,63(15):157801-157801.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-WLXB201415056.htm

|

| [14] |

LEE H M,CHOI S Y,JUNG A. Direct deposition of highly conductive aluminum thin film on substrate by solution-dipping process[J]. ACS Applied Materials Interfaces,2013,5(11):4581-4585. doi: 10.1021/am400812e

|

| [15] |

XIONG Y Q,LI X C,CHEN Q,et al.. Characteristics and properties of metal aluminum thin films prepared by electron cyclotron resonance plasma-assisted atomic layer deposition technology[J]. Chinese Physics B,2012,21(7):078105. doi: 10.1088/1674-1056/21/7/078105

|

| [16] |

BRADFORD A P,HASS G,OSANTOWSKI J F,et al.. Preparation of mirror coatings for the vacuum ultraviolet in a 2-m evaporator[J]. Applied Optics,1969,8(6):1183-1189. doi: 10.1364/AO.8.001183

|

| [17] |

WILBRANDT S,STENZEL O,NAKAMURA H,et al.. Protected and enhanced aluminum mirrors for the VUV[J]. Applied Optics,2014,53(4):A125-A130. doi: 10.1364/AO.53.00A125

|

| [18] |

YANG M,GATTO A,KAISER N. Highly reflecting aluminum-protected optical coatings for the vacuum-ultraviolet spectral range[J]. Applied Optics,2006,45(1):178-183. doi: 10.1364/AO.45.000178

|

| [19] |

SCH RMANN M,JOBST P J,YULIN S,et al.. Optical reflector coatings for astronomical applications from EUV to IR[J]. SPIE,2012:8450:84502K-8. http://cn.bing.com/academic/profile?id=2089176272&encoded=0&v=paper_preview&mkt=zh-cn

|

| [20] |

LI Z Z,GAO J S,YANG H G,et al.. Roughness reduction of large-area high-quality thick Al films for echelle gratings by multi-step deposition method[J]. Optics Express,2015,23(18):23738-23747. doi: 10.1364/OE.23.023738

|

| [21] |

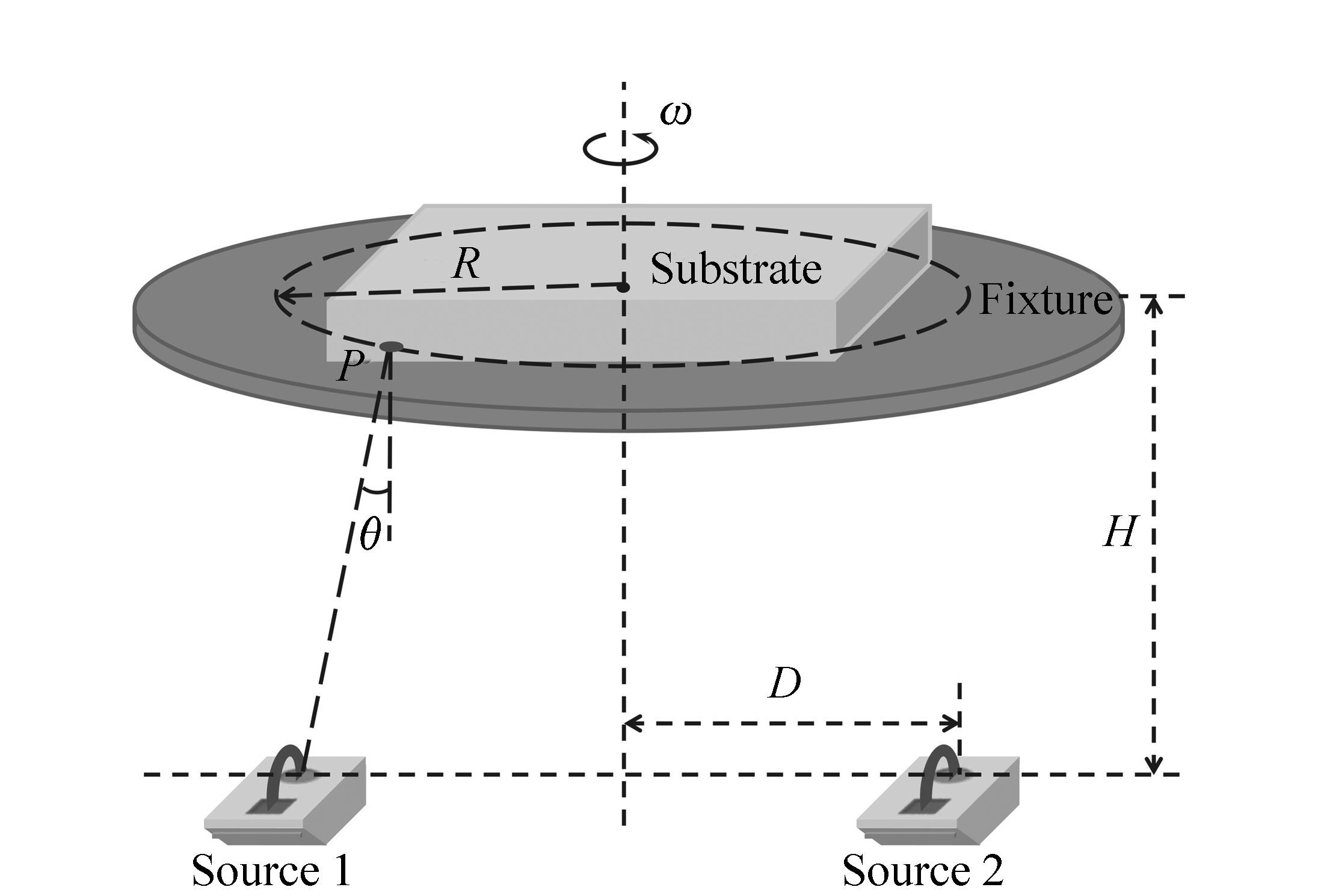

YANG H G,LI Z Z,WANG X Y,et al.. Radial-quality uniformity investigations of large-area thick Al films[J]. Optical Engineering,2015,54(4):045106-045106. doi: 10.1117/1.OE.54.4.045106

|

| [22] |

LAI Z W,SARMA S D. Kinetic growth with surface relaxation:Continuum versus atomistic models[J]. Physical Review Letters,1991,66(18):2348. doi: 10.1103/PhysRevLett.66.2348

|

| [23] |

TU K N,GUSAK A M,SOBCHENKO I. Linear rate of grain growth in thin films during deposition[J]. Physical Review B,2003,67(24):245408. doi: 10.1103/PhysRevB.67.245408

|

| [24] |

SROLOVITZ D J,BATTAILE C C,LI X,et al.. Simulation of faceted film growth in two-dimensions:microstructure, morphology and texture[J]. Acta Materialia,1999,47(7):2269-2281. doi: 10.1016/S1359-6454(99)00086-5

|

| [25] |

ROBBIE K,SIT J C,BRETT M J. Advanced techniques for glancing angle deposition[J]. J. Vacuum Science Technology B,1998,16(3):1115-1122. doi: 10.1116/1.590019

|

| [26] |

KARABACAK T. Thin-film growth dynamics with shadowing and re-emission effects[J]. J. Nanophotonics,2011,5(1):052501-052501-18. doi: 10.1117/1.3543822

|

| [27] |

CHANG J F,KUO H H,LEU I C,et al.. The effects of thickness and operation temperature on ZnO:Al thin film CO gas sensor[J]. Sensors and Actuators B:Chemical,2002,84(2):258-264. http://cn.bing.com/academic/profile?id=2025933302&encoded=0&v=paper_preview&mkt=zh-cn

|

| [28] |

ONISHI T,IWAMURA E,TAKAGI K. Morphology of sputter deposited Al alloy films[J]. Thin Solid Films,1999,340(1):306-316. http://cn.bing.com/academic/profile?id=2055619502&encoded=0&v=paper_preview&mkt=zh-cn

|

| [29] |

HWANG S J,LEE J H,JEONG C O,et al.. Effect of film thickness and annealing temperature on hillock distributions in pure Al films[J]. Scripta Materialia,2007,56(1):17-20. doi: 10.1016/j.scriptamat.2006.09.001

|

下载:

下载: