High anti-icing performance of coating-free superhydrophobic metal surfaces via femtosecond laser processing

doi: 10.37188/CO.EN-2025-0013

-

摘要:

超疏水表面作为一种有效的被动防冰方法,可以减少低温环境下金属表面的结冰。然而,由于其通常采用的有机物修饰在恶劣环境下易老化,从而导致防冰性能下降或完全失效等严重问题。本文采用飞秒激光掺杂制备微结构方法在对铝合金表面进行微观形貌和化学成分的同时改变,实现材料表面无有机涂层的超疏水防冰效果。与未加工铝合金和传统氟硅烷改性的铝合金表面相比较,激光掺杂加工后的铝合金表面具有较低的热导率和仿生蚁丘群结构,使得其具有良好的延迟结冰时间(803.3 s)和较低的冰附着力(16 μN)。此外,这种本征超疏水金属表面在防冰性能方面也表现出优异的环境耐久性。这些研究结果证实了我们获得的无有机涂层超疏水样品在防结冰方面的有效性。

Abstract:As an efficient passive anti-icing method, the superhydrophobic surface can reduce icing process on metals in low temperatures. However, the usual organic low-surface-energy decorations are often prone to age especially in harsh environments, leading to a decrease or complete failure of the anti-icing performance. Here, we adopt a method of femtosecond laser microstructuring to achieve inorganic superhydrophobic aluminum alloys through simultaneously modifying the surface profile and compositions. The obtained bionic anthill tribe structure with the low thermal conductivity, exhibits the superior delayed freezing time (803.3 s) and the low ice adhesion (16 μN) in comparison to the fluorosilane modified and bare Al surfaces. Moreover, such an inherently superhydrophobic metal surface also shows the exceptional environmental durability in anti-icing performance, which confirms the effectiveness of our superhydrophobic surface without the need for organic coatings.

-

Key words:

- inorganic superhydrophobic /

- anti-icing /

- Al alloys /

- femtosecond laser

-

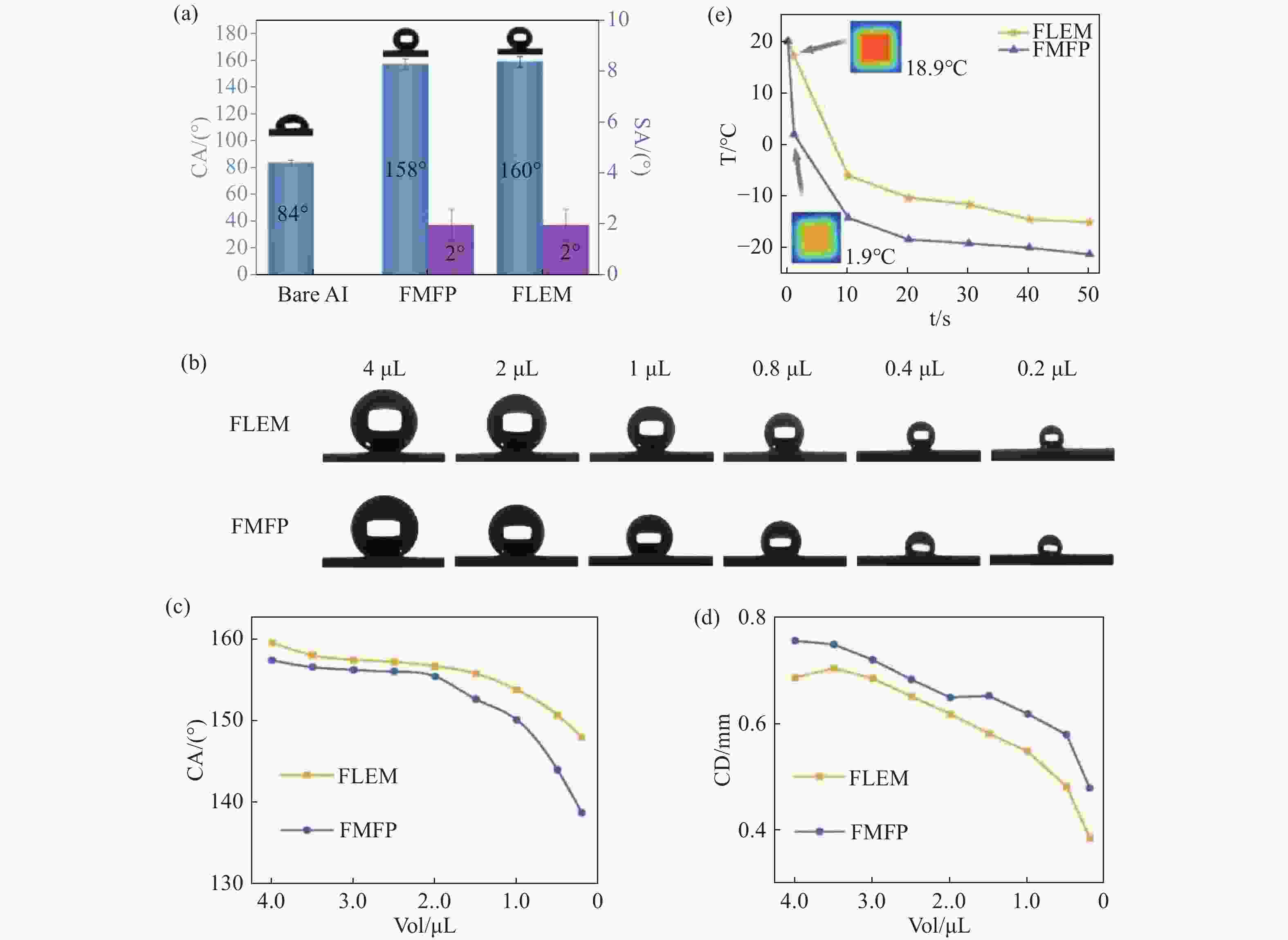

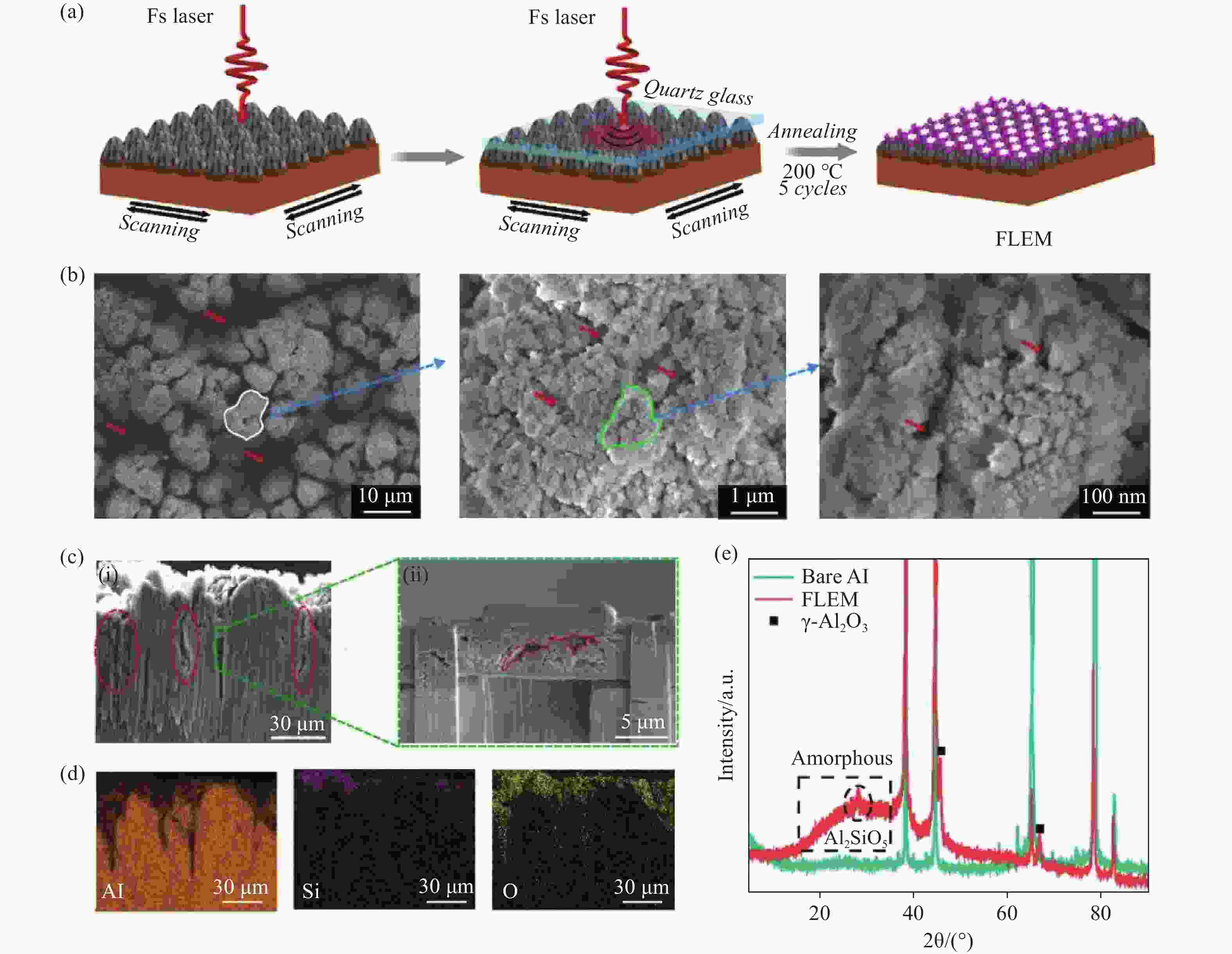

Figure 1. Characterizations of the surface profile and chemical compositions on the FLEM sample. (a) Schematic diagram of the FLEM method. (b) Top-view SEM images of the surface morphology. (c) Cross-sectional SEM images of the structure (i) and the corresponding local area (ii). (d) EDX images of the cross-sectional area of the structure. (e) GIXRD spectra for the bare Al and the FLEM sample.

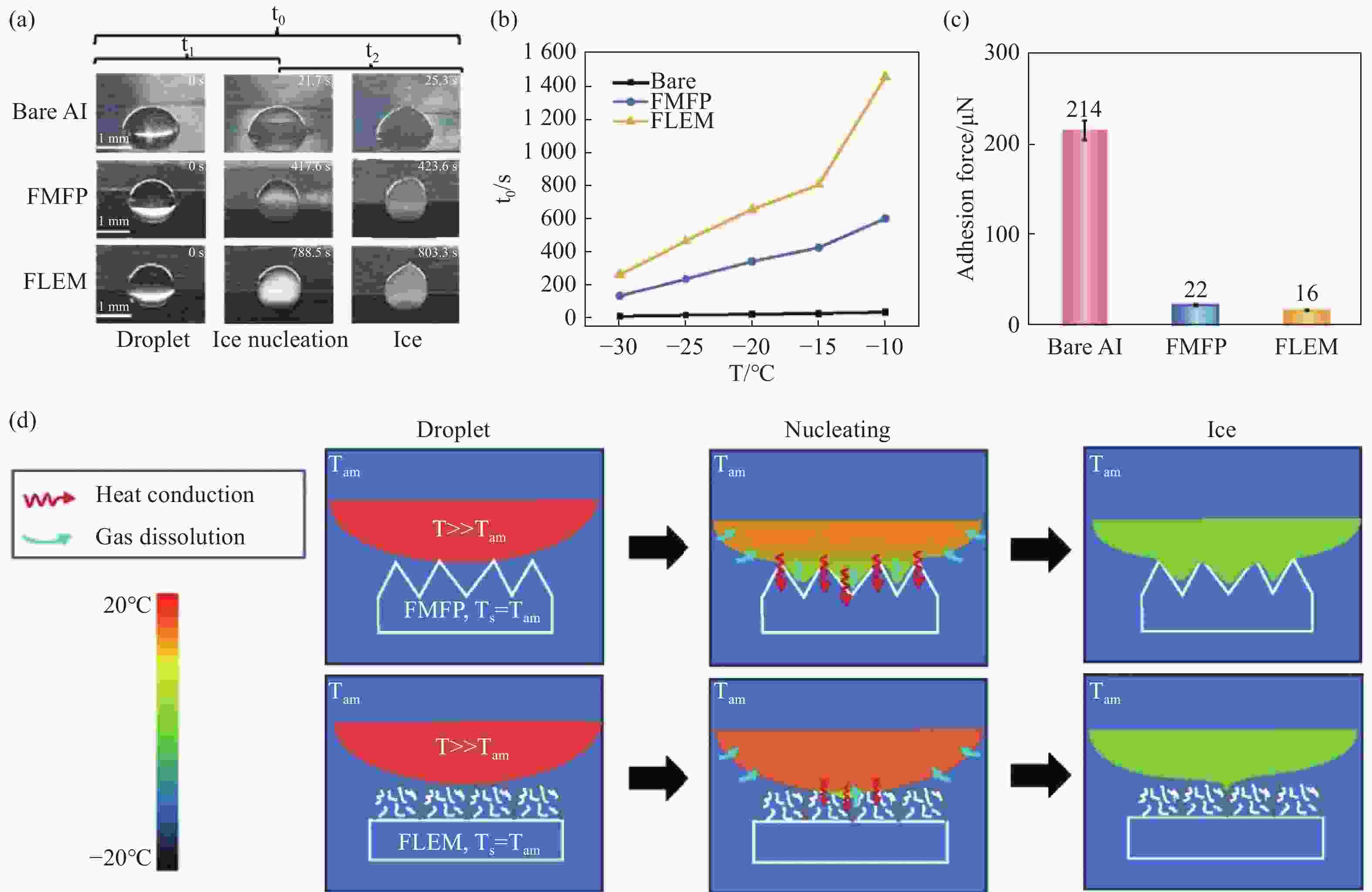

Figure 2. Characterizations of the superhydrophobic and anti-icing performance of different samples (indoor conditions). (a) Measured contact angle (CA) and sliding angle (SA) for three different surfaces. (b) Time-evolution of the droplet volume on the FLEM and FMFP surfaces during the evaporation experiment. Measured CA (c) and CD(d) variations with the water droplet volume. (e) Measured heat transfer efficiencies of the FMFP and FLEM samples placed on a Peltier cooling plate.

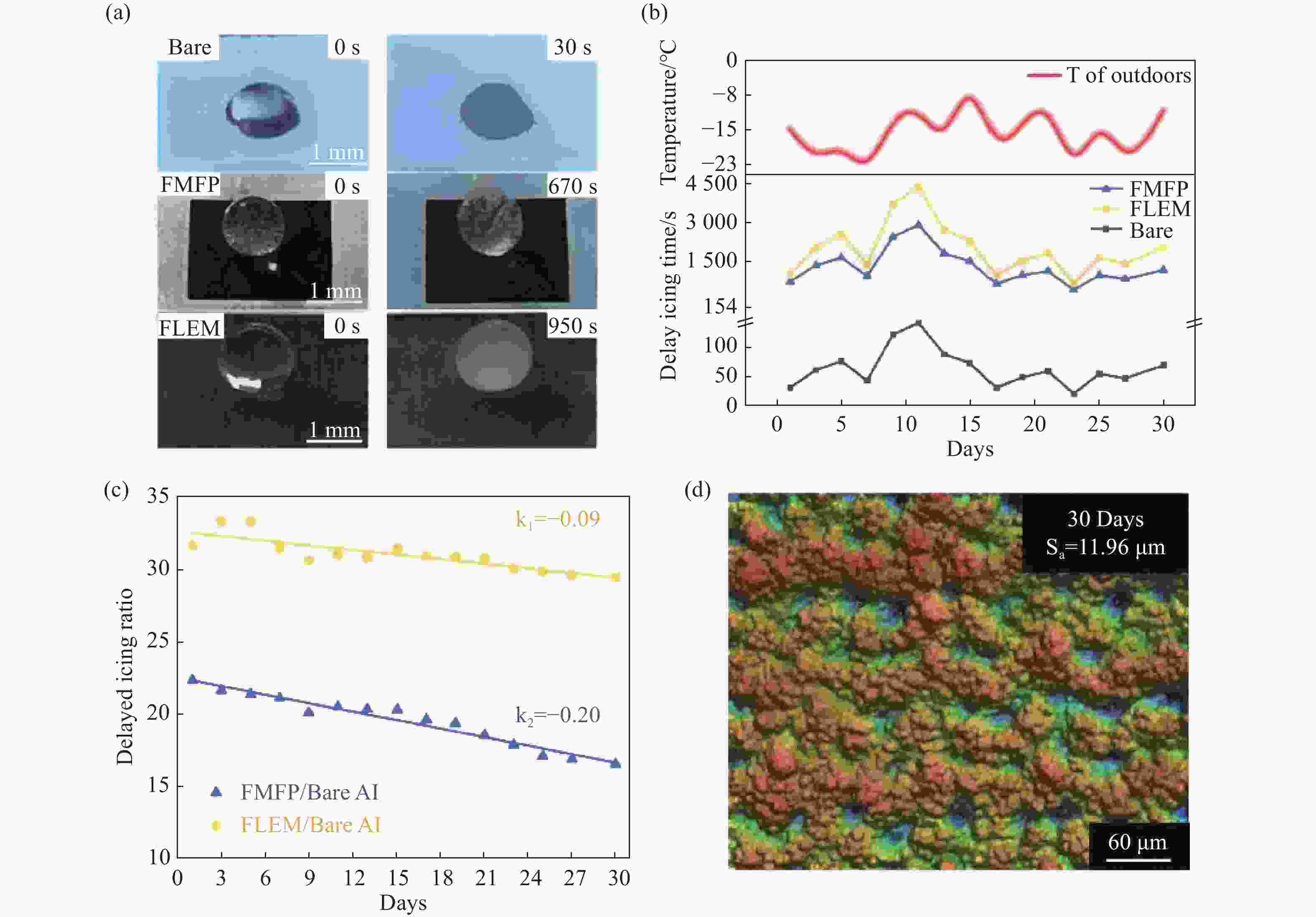

Figure 3. Measured anti-icing performances and underlying mechanisms for the FLEM and FMFP surfaces. (a) The whole droplet icing process on the bare Al, FMFP and FLEM surfaces. (b) The measured dependence of delayed icing time t0 on the ambient temperature Tam for three different surfaces. (c) The measured adhesion force of ice droplet on these surfaces at the ambient temperature of Tam = −15 °C. (d) Proposed scenarios for the anti-icing process on the FLEM and FMFP surfaces.

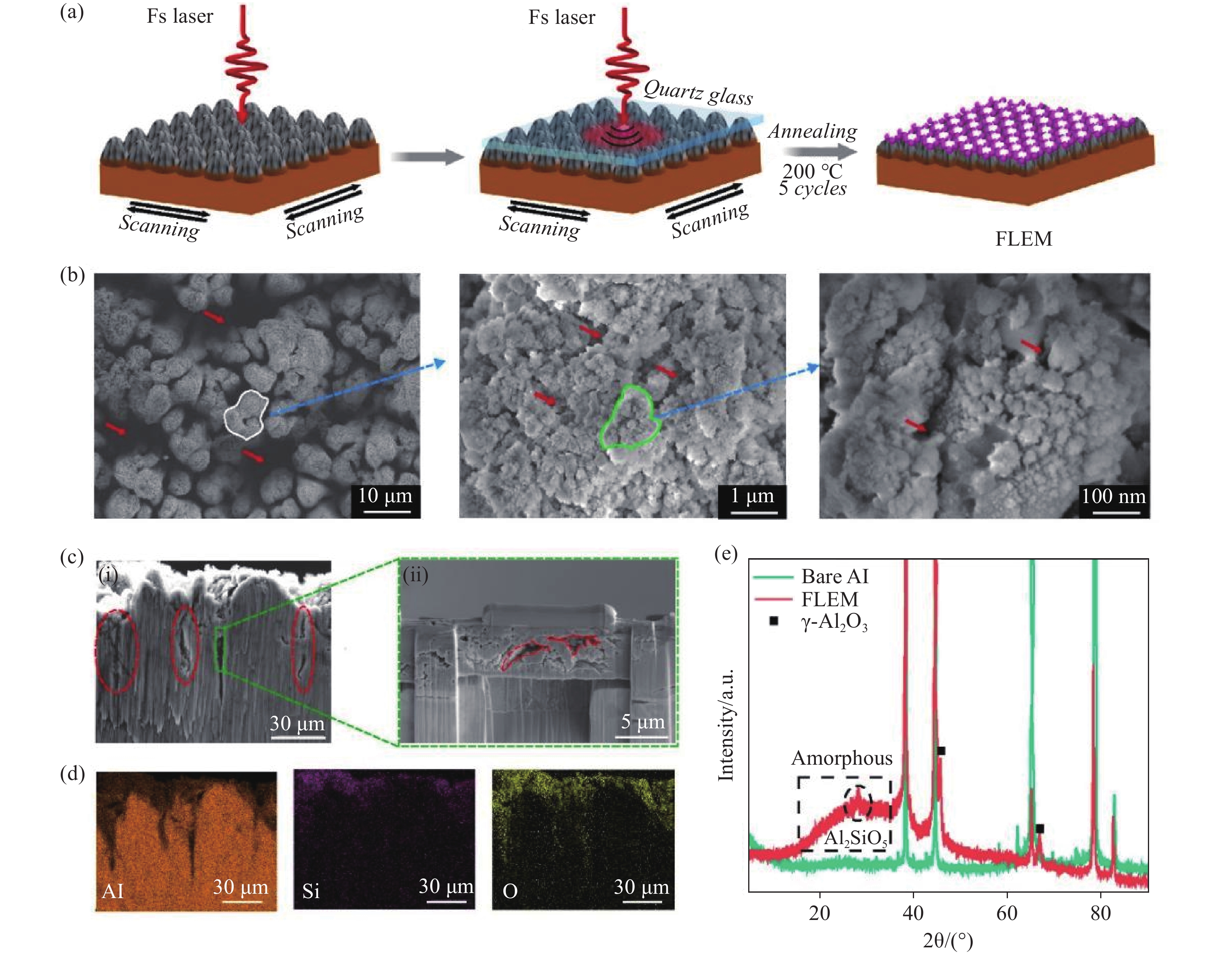

Figure 4. Outdoor anti-icing performance of different samples. (a) Freezing process of a water droplet on different surfaces in the outdoor winter environment. (b) Measured icing time delay for three different samples as a function of the exposing days with variable weather conditions. (c) Available delayed icing ratios of the FLEM and FMFP samples to the bare surface. (d) Microscopic examination of the surface morphology on the FLEM surface after 30 days of the outdoor environment exposure.

-

[1] XING M B, ZHANG ZH T, WANG Z Y, et al. Freezing process of water droplet on the cold plate surfaces with different wettability[J]. International Journal of Heat and Mass Transfer, 2024, 230: 125773. doi: 10.1016/j.ijheatmasstransfer.2024.125773 [2] SUN R J, HOU B, HUANG J J, et al. Wettability/anti-icing properties of hierarchical micro/nanostructured copper surface prepared by Micro milling and chemical etching[J]. Sustainable Materials and Technologies, 2024, 42: e01136. doi: 10.1016/j.susmat.2024.e01136 [3] ZHANG F, YAN H J, CHEN M J. Multi-scale superhydrophobic surface with excellent stability and solar-thermal performance for highly efficient anti-icing and deicing[J]. Small, 2024, 20(32): 2312226. doi: 10.1002/smll.202312226 [4] ZHANG Y J, ZHANG L, LUO G S. Study on de-icing criterion of anti-icing coating and simulation analysis method of mechanical de-icing process for polar ship superstructure[J]. Ocean Engineering, 2023, 288: 115811. doi: 10.1016/j.oceaneng.2023.115811 [5] WANG SH SH, CHANG SH N, QI H F, et al. Experimental study of icing and deicing situations of different wettability surfaces composite electric heating[J]. Applied Thermal Engineering, 2024, 238: 122045. doi: 10.1016/j.applthermaleng.2023.122045 [6] IBRAHIM Y, KEMPERS R, AMIRFAZLI A. 3D printed electro-thermal anti- or de-icing system for composite panels[J]. Cold Regions Science and Technology, 2019, 166: 102844. doi: 10.1016/j.coldregions.2019.102844 [7] GRUBER M R, HOFKO B, HOFFMANN M, et al. Deicing performance of common deicing agents for winter maintenance with and without corrosion-inhibiting substances[J]. Cold Regions Science and Technology, 2023, 208: 103795. doi: 10.1016/j.coldregions.2023.103795 [8] WU Y L, DONG L, SHU X, et al. Recent advancements in photothermal anti-icing/deicing materials[J]. Chemical Engineering Journal, 2023, 469: 143924. doi: 10.1016/j.cej.2023.143924 [9] ZHANG ZH, ZHANG F, MUHAMMED R D. Effect of air volume fraction on the thermal conductivity of compacted bentonite materials[J]. Engineering Geology, 2021, 284: 106045. doi: 10.1016/j.enggeo.2021.106045 [10] LI X Y, WU Y H, LIN X, et al. Eco-friendly fabrication of robust superhydrophobic coating with excellent anti-corrosion and anti-icing properties through using submillimeter particles as protective structure[J]. Surface and Coatings Technology, 2024, 494: 131494. doi: 10.1016/j.surfcoat.2024.131494 [11] JIN ZH Y, CHENG X Y, YANG ZH G. Experimental investigation of the successive freezing processes of water droplets on an ice surface[J]. International Journal of Heat and Mass Transfer, 2017, 107: 906-915. doi: 10.1016/j.ijheatmasstransfer.2016.11.001 [12] CHEN Z L, SONG L, WANG Y, et al. Air pocket-optimization strategy for micro/nanostructures fabricated by femtosecond laser technology for anti-icing performance improvement[J]. Applied Surface Science, 2024, 655: 159454. doi: 10.1016/j.apsusc.2024.159454 [13] LIU Y, LI X L, JIN J F, et al. Anti-icing property of bio-inspired micro-structure superhydrophobic surfaces and heat transfer model[J]. Applied Surface Science, 2017, 400: 498-505. doi: 10.1016/j.apsusc.2016.12.219 [14] PAN R, CAI M Y, LIU W J, et al. Extremely high Cassie–Baxter state stability of superhydrophobic surfaces via precisely tunable dual-scale and triple-scale micro–nano structures[J]. Journal of Materials Chemistry A, 2019, 7(30): 18050-18062. doi: 10.1039/C9TA04484A [15] TIAN Z, FAN P X, ZHU D Y, et al. Anti-ice-pinning superhydrophobic surfaces for extremely low ice adhesion[J]. Chemical Engineering Journal, 2023, 473: 145382. doi: 10.1016/j.cej.2023.145382 [16] LAMBLEY H, GRAEBER G, VOGT R, et al. Freezing-induced wetting transitions on superhydrophobic surfaces[J]. Nature Physics, 2023, 19(5): 649-655. [17] XU L Y, YANG L L, YANG SH, et al. Earthworm-inspired ultradurable superhydrophobic fabrics from adaptive wrinkled skin[J]. ACS Applied Materials & Interfaces, 2021, 13(5): 6758-6766. [18] SAJI V S. Superhydrophobic surfaces and coatings by electrochemical anodic oxidation and plasma electrolytic oxidation[J]. Advances in Colloid and Interface Science, 2020, 283: 102245. doi: 10.1016/j.cis.2020.102245 [19] BOINOVICH L B, MODIN E B, SAYFUTDINOVA A R, et al. Combination of functional nanoengineering and nanosecond laser texturing for design of superhydrophobic aluminum alloy with exceptional mechanical and chemical properties[J]. ACS Nano, 2017, 11(10): 10113-10123. doi: 10.1021/acsnano.7b04634 [20] HE Y CH, WANG L X, WU T N, et al. Facile fabrication of hierarchical textures for substrate-independent and durable superhydrophobic surfaces[J]. Nanoscale, 2022, 14(26): 9392-9400. doi: 10.1039/D2NR02157A [21] TANG B H, WANG Q, HAN X CH, et al. Fabrication of anti-icing/de-icing surfaces by femtosecond laser[J]. Frontiers in Chemistry, 2022, 10: 1073473. doi: 10.3389/fchem.2022.1073473 [22] WANG L ZH, ZHAO H Y, ZHU D Y, et al. A review on ultrafast laser enabled excellent superhydrophobic anti-icing performances[J]. Applied Sciences, 2023, 13(9): 5478. doi: 10.3390/app13095478 [23] ZHANG J L, REN F ZH, YANG Q, et al. Glass catfish inspired subaquatic abrasion-resistant anti-fouling window fabricated by femtosecond laser electrodeposition[J]. International Journal of Extreme Manufacturing, 2025, 7(1): 015004. doi: 10.1088/2631-7990/ad878d [24] PAN R, ZHANG H J, ZHONG M L. Triple-scale superhydrophobic surface with excellent anti-icing and icephobic performance via ultrafast laser hybrid fabrication[J]. ACS Applied Materials & Interfaces, 2021, 13(1): 1743-1753. [25] XUAN S S, ZHUO L J, LI G Q, et al. Micro/nano hierarchical crater-like structure surface with mechanical durability and low-adhesion for anti-icing/deicing[J]. Small, 2024, 20(43): 2404979. doi: 10.1002/smll.202404979 [26] WANG L ZH, LI D ZH, JIANG G CH, et al. Dual-energy-barrier stable superhydrophobic structures for long icing delay[J]. ACS Nano, 2024, 18(19): 12489-12502. doi: 10.1021/acsnano.4c02051 [27] TANG A M, CUI Y J, LE T T. A study on the thermal conductivity of compacted bentonites[J]. Applied Clay Science, 2008, 41(3-4): 181-189. doi: 10.1016/j.clay.2007.11.001 [28] YAN D D, XU W J, ZOU T T, et al. Durable organic coating-free superhydrophobic metal surface by paracrystalline state formation[J]. Advanced Materials, 2025, 37(1): 2412850. doi: 10.1002/adma.202412850 [29] CHEN Q, WANG SH B, LI ZH. Fabrication and characterization of aluminum silicate fiber–reinforced hollow mesoporous silica microspheres composites[J]. Microporous and Mesoporous Materials, 2012, 152: 104-109. doi: 10.1016/j.micromeso.2011.11.053 [30] HAO M Y, CHEN H L, XIA CH K, et al. Al2O3-SiO2 aerogel reinforced with aluminum silicate nanofibers: a strategy to preserve the properties of Al2O3-SiO2 aerogel[J]. Journal of Sol-Gel Science and Technology, 2024, 109(2): 523-533. doi: 10.1007/s10971-023-06286-5 [31] OCEJO M, GOITI E, SALINAS-GARZÓN J, et al. Preparation and properties of aluminosilicate aerogels from boehmite and waterglass[J]. Materials Chemistry and Physics, 2024, 315: 128912. doi: 10.1016/j.matchemphys.2024.128912 [32] ICKES L, WELTI A, HOOSE C, et al. Classical nucleation theory of homogeneous freezing of water: thermodynamic and kinetic parameters[J]. Physical Chemistry Chemical Physics, 2015, 17(8): 5514-5537. doi: 10.1039/C4CP04184D [33] ZOBRIST B, KOOP T, LUO B P, et al. Heterogeneous ice nucleation rate coefficient of water droplets coated by a nonadecanol monolayer[J]. The Journal of Physical Chemistry C, 2007, 111(5): 2149-2155. doi: 10.1021/jp066080w -

下载:

下载: