-

摘要:

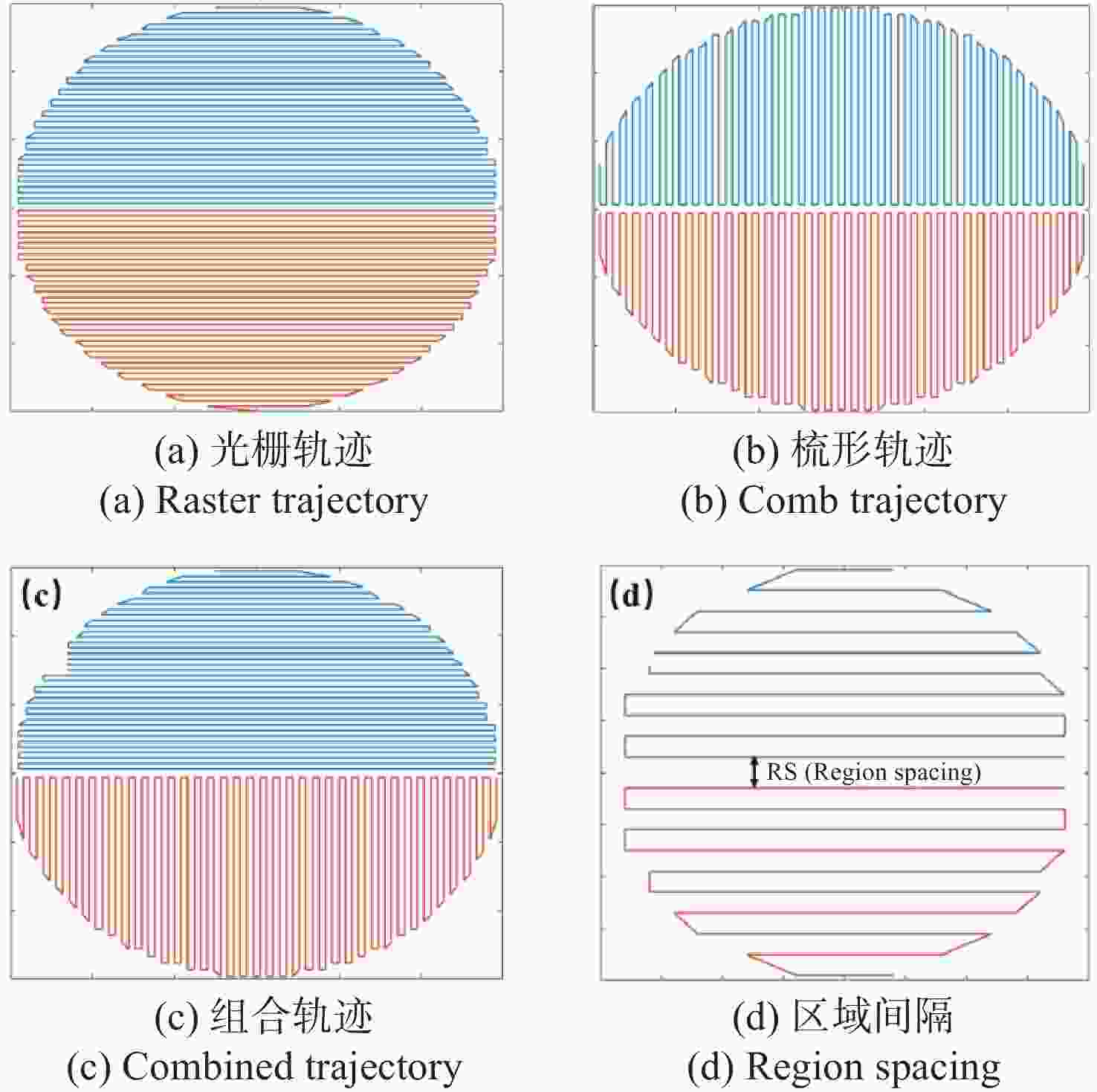

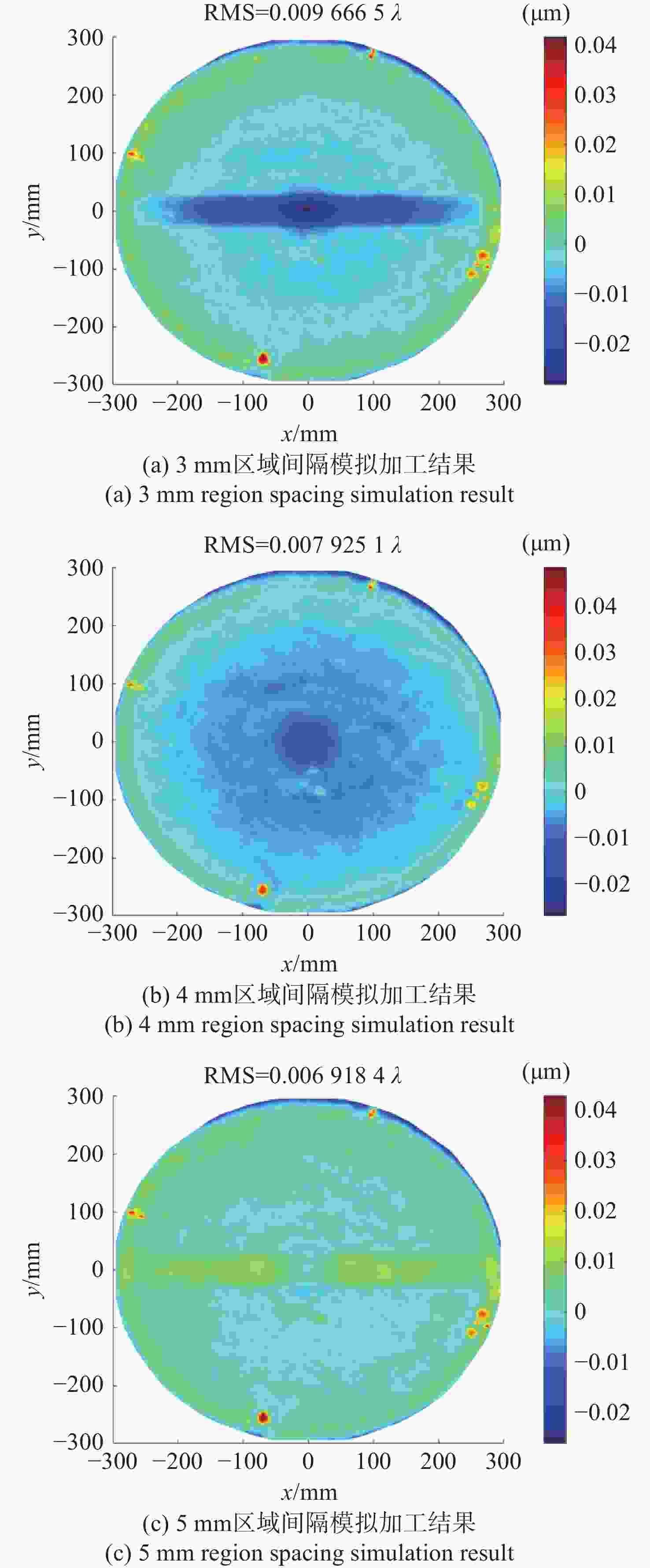

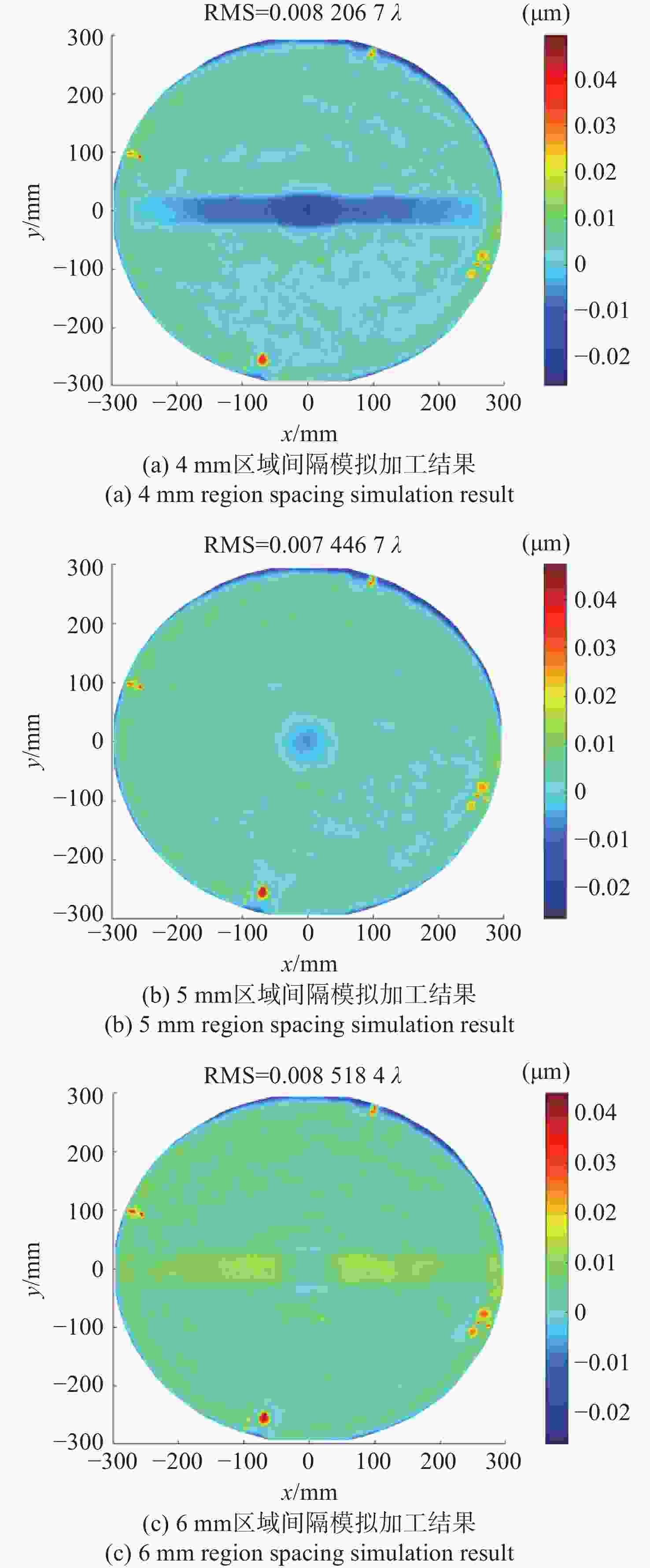

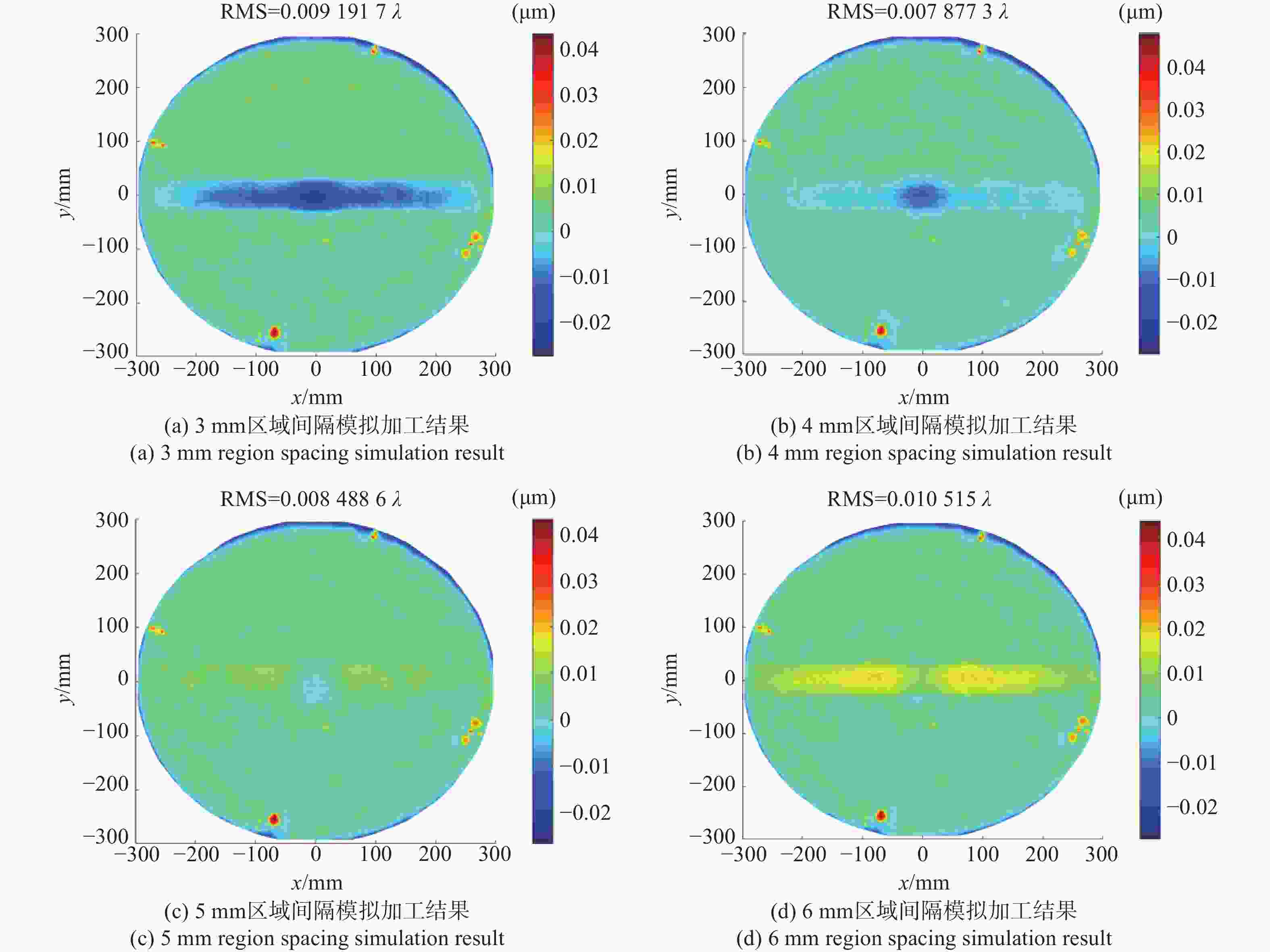

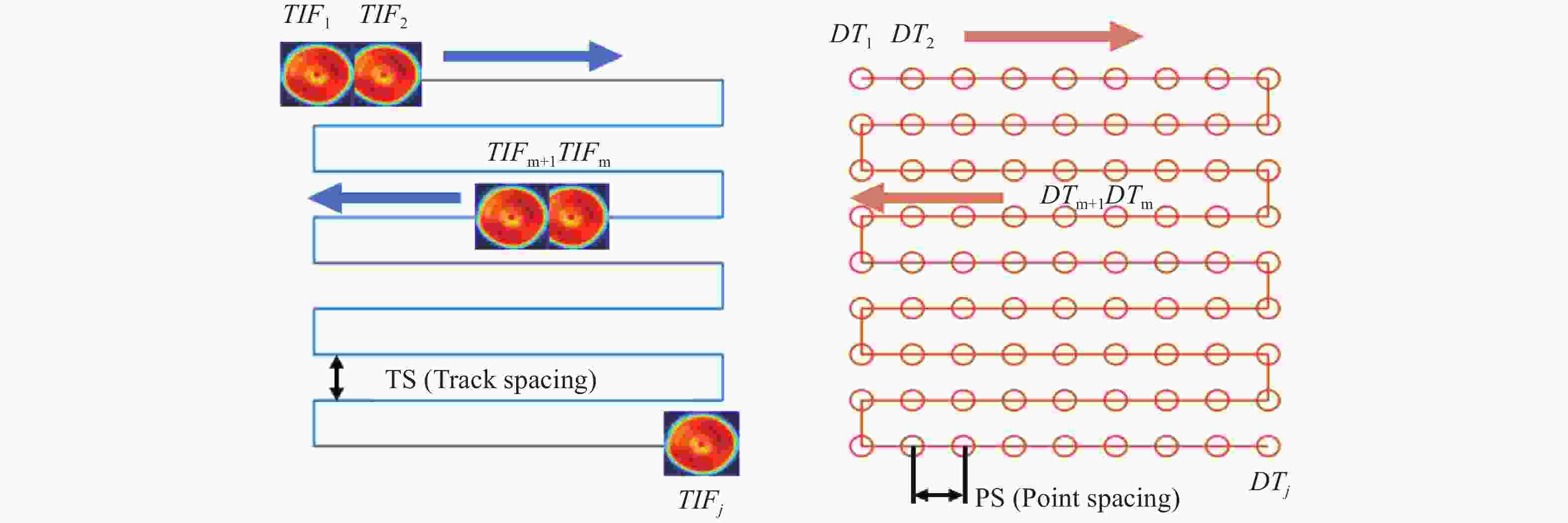

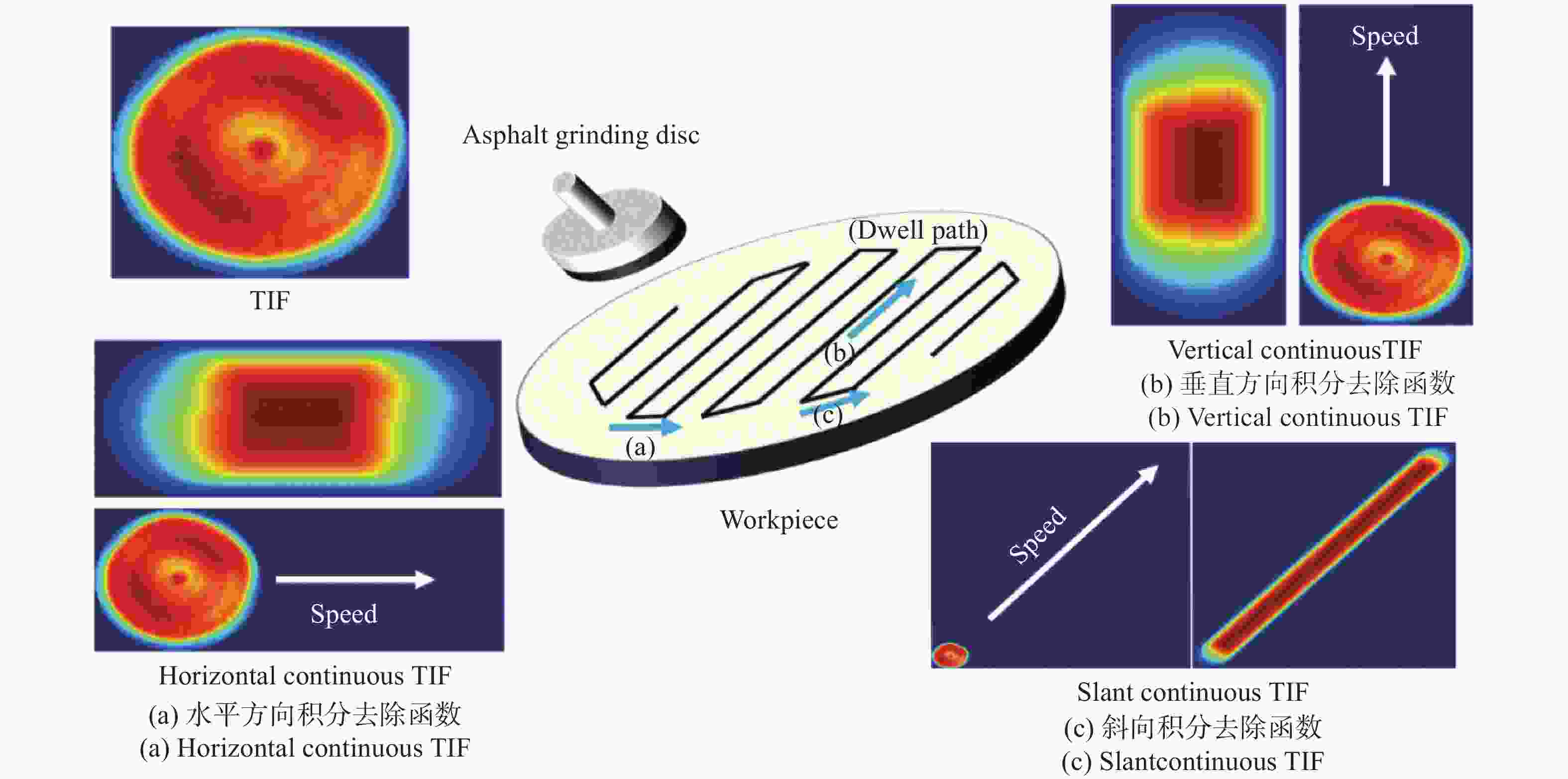

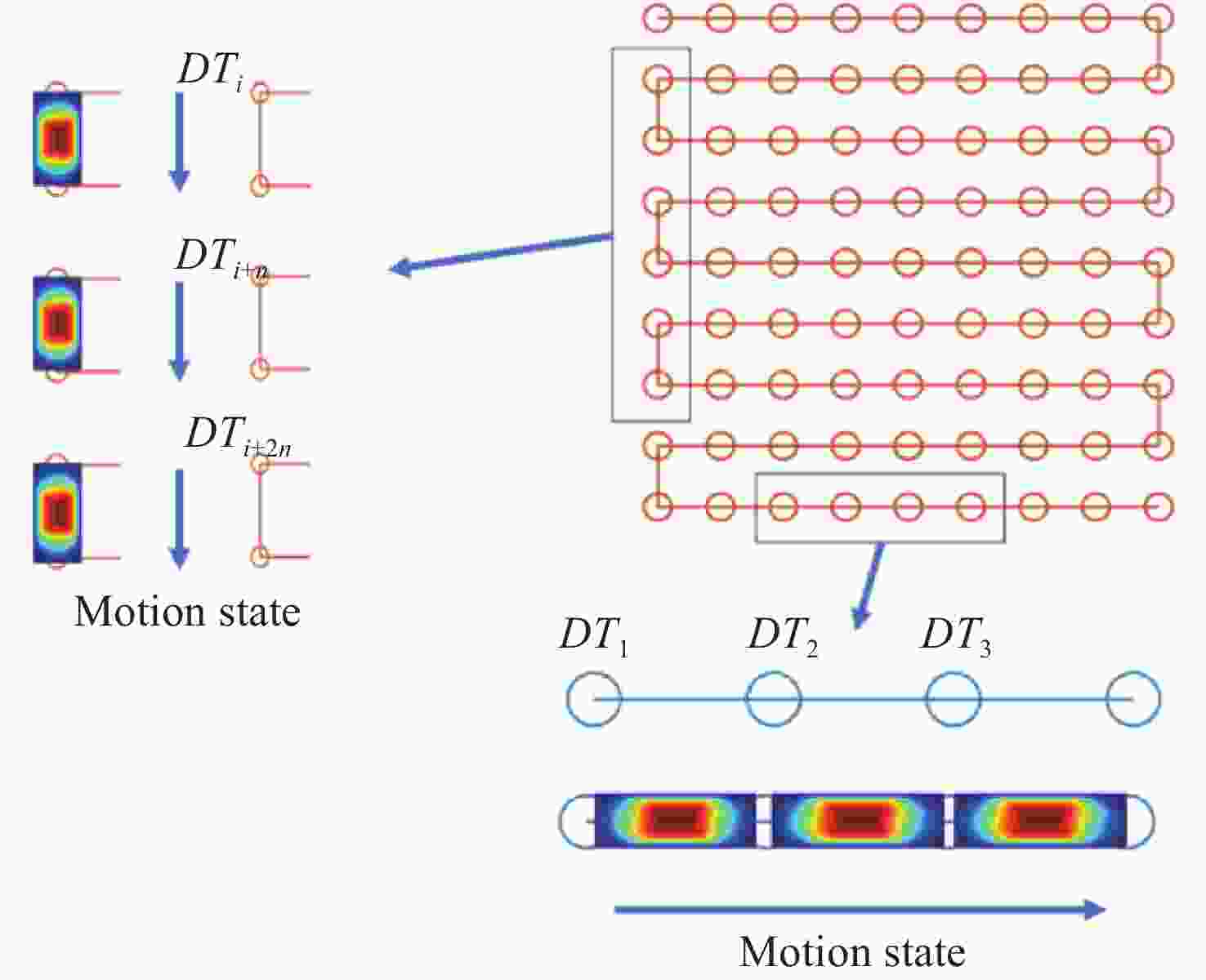

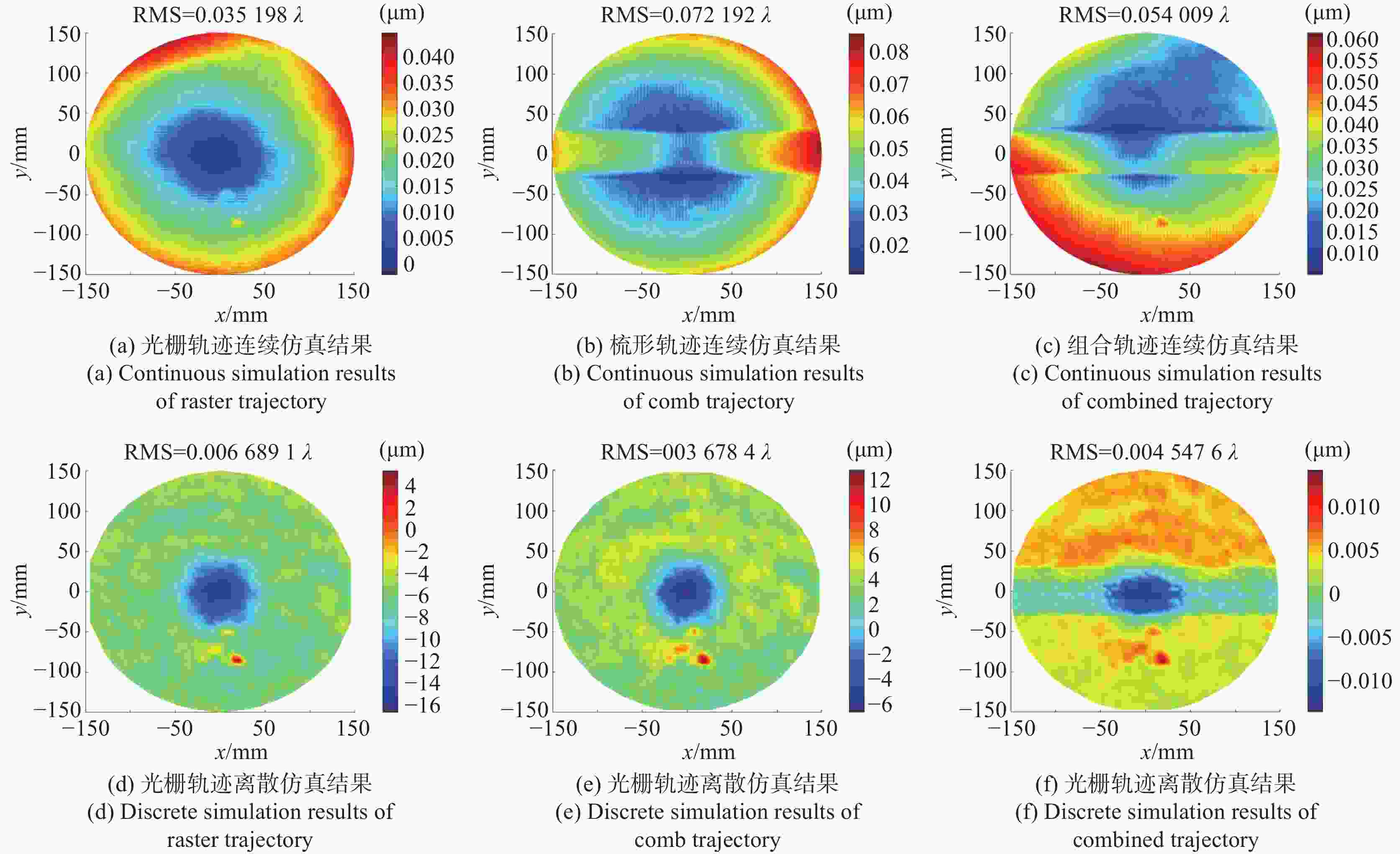

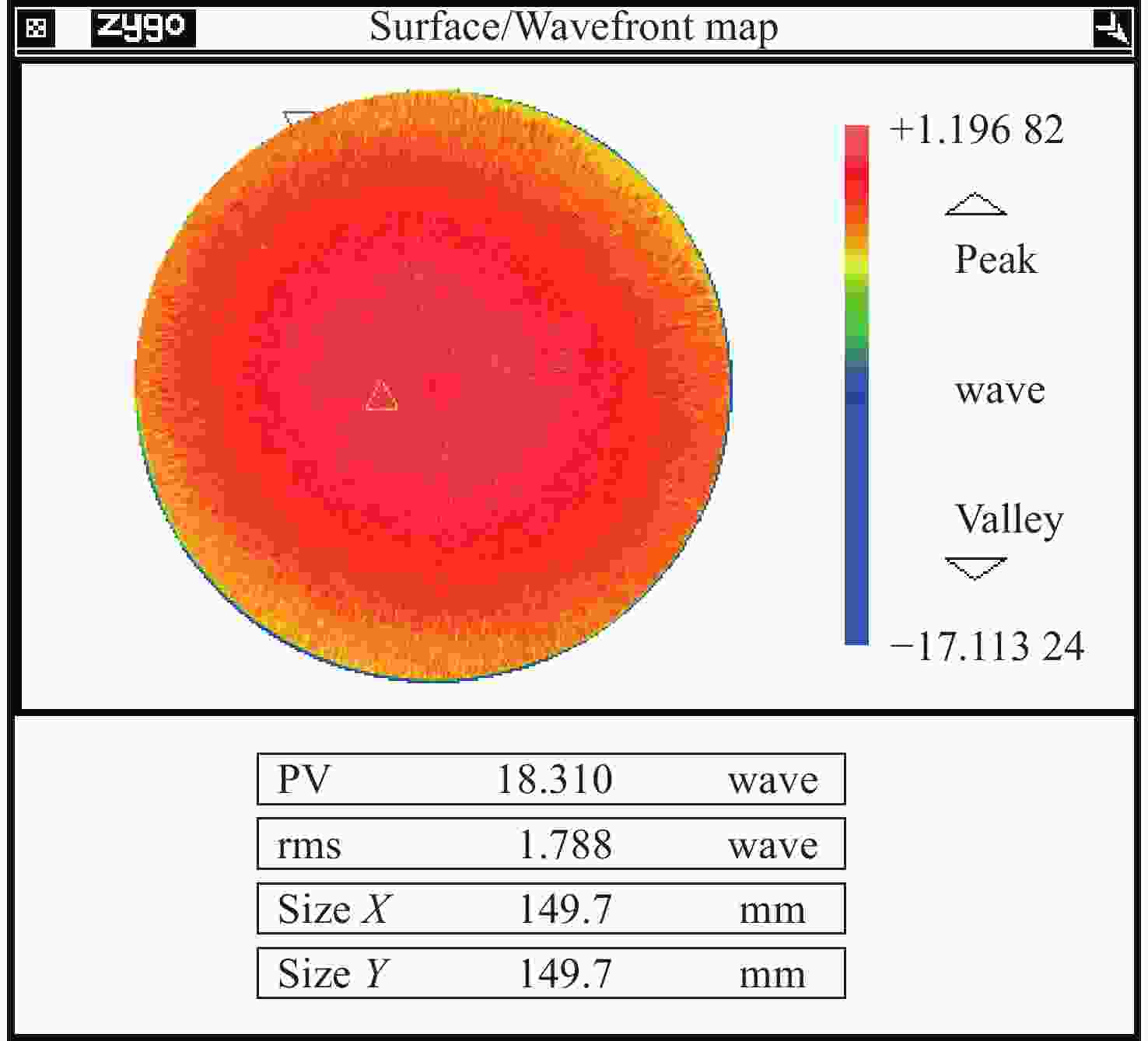

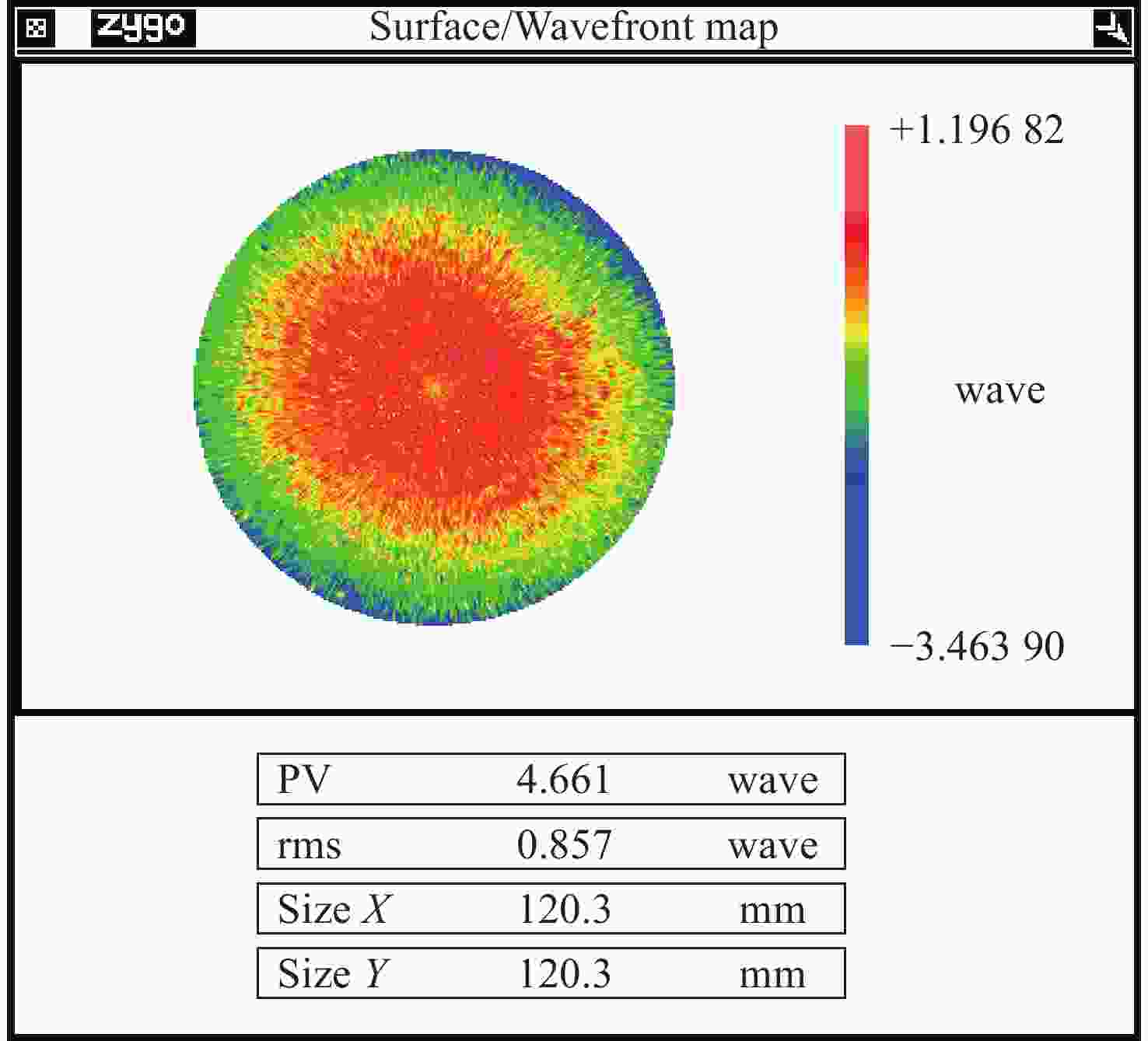

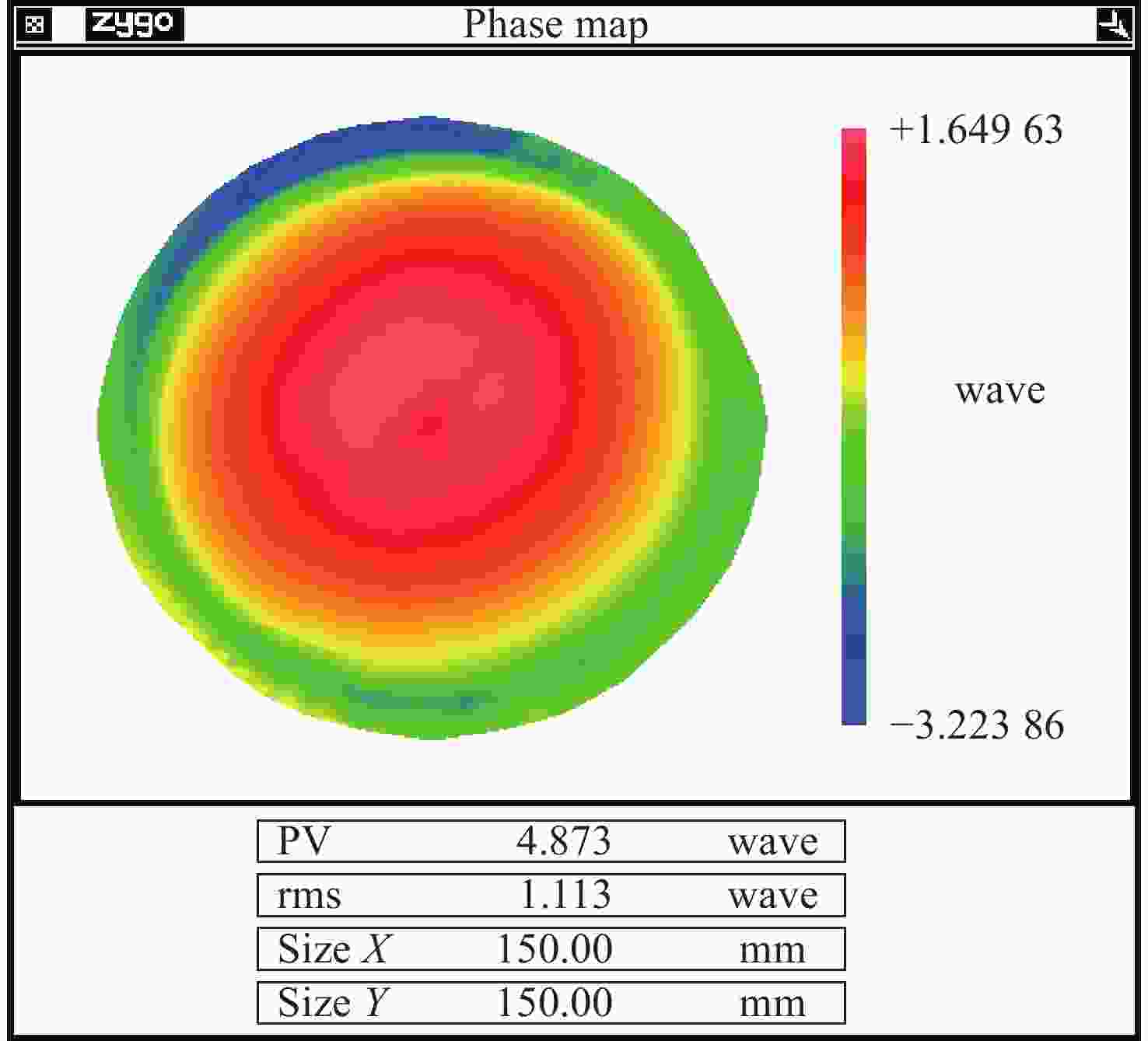

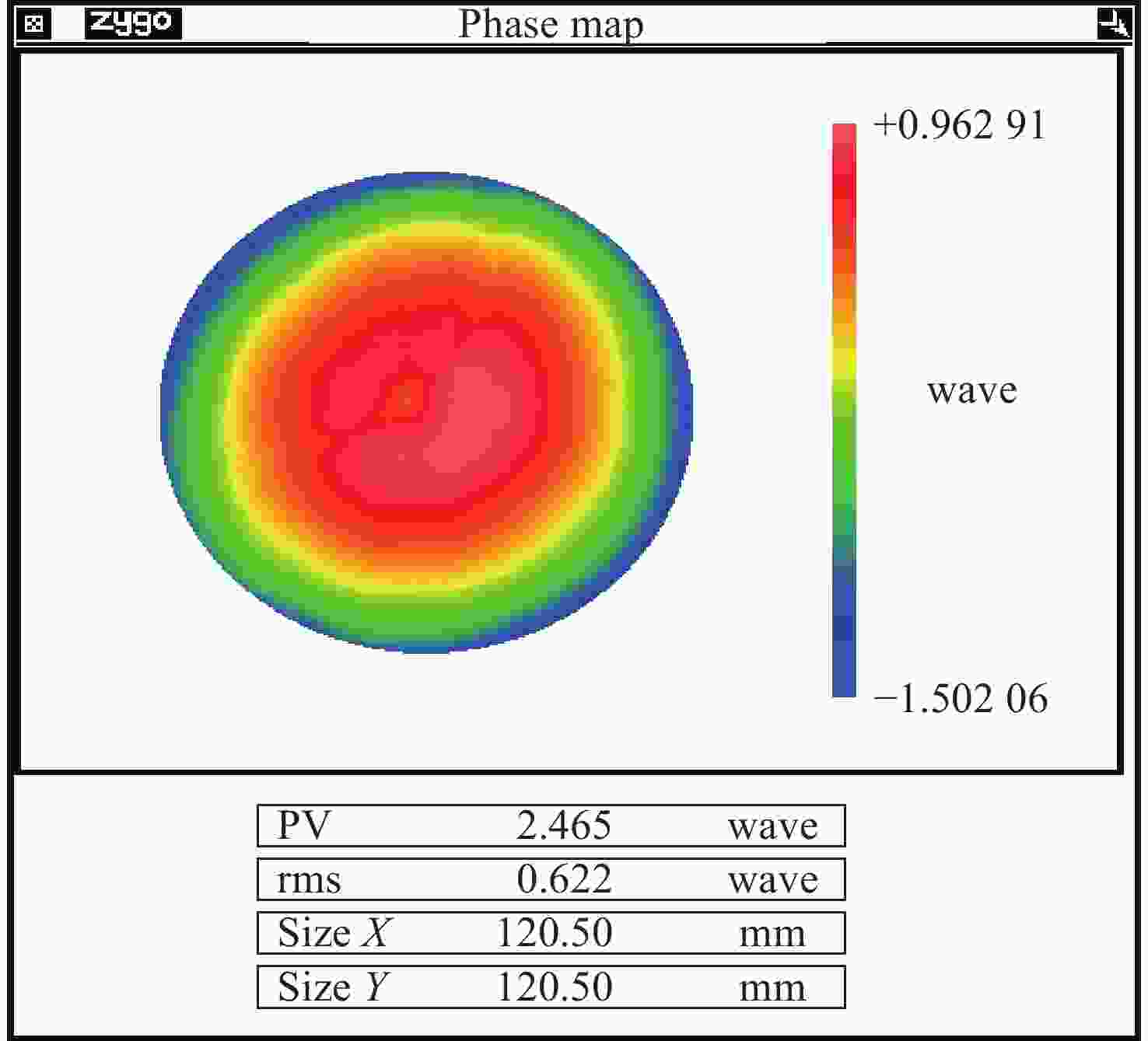

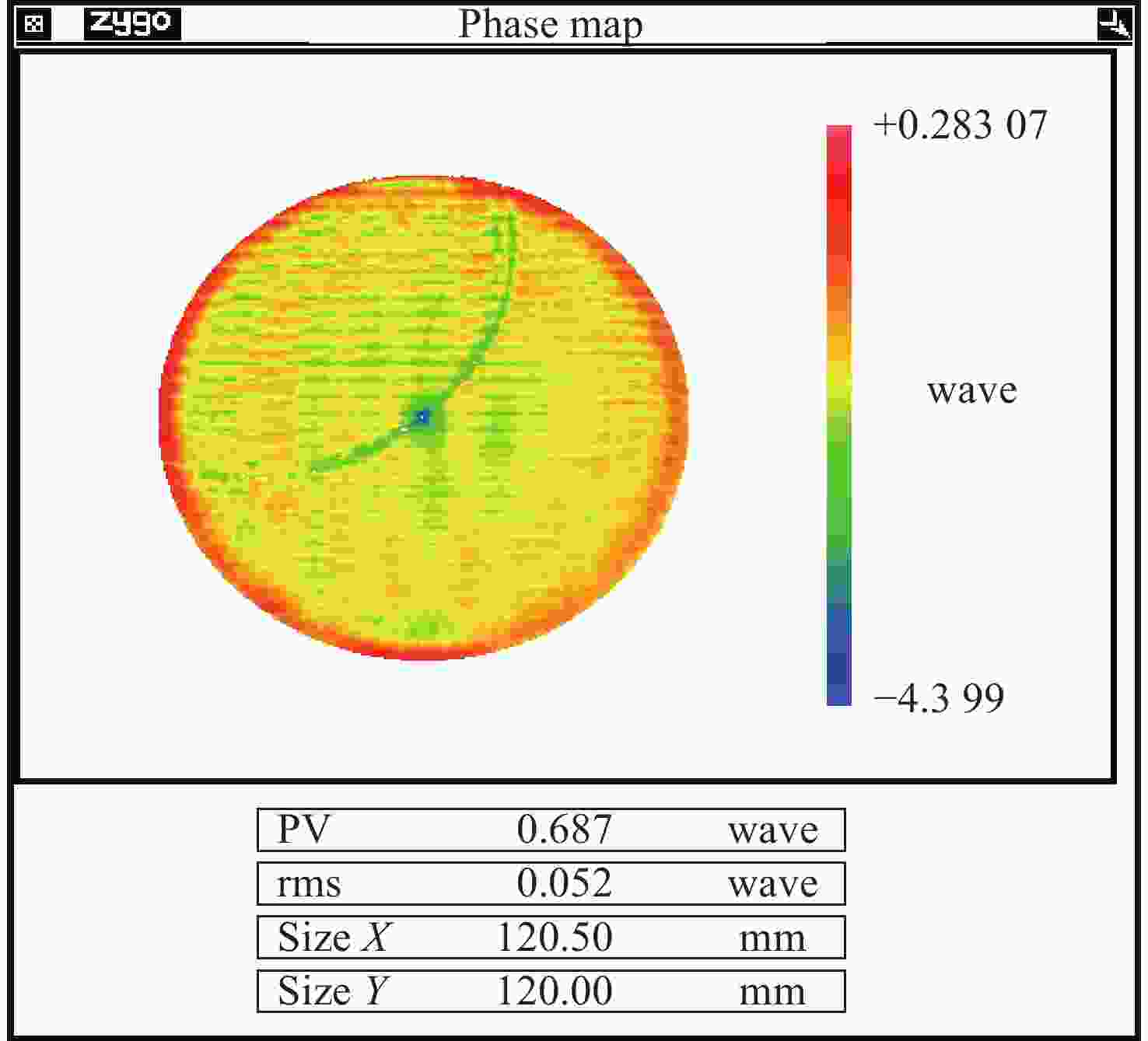

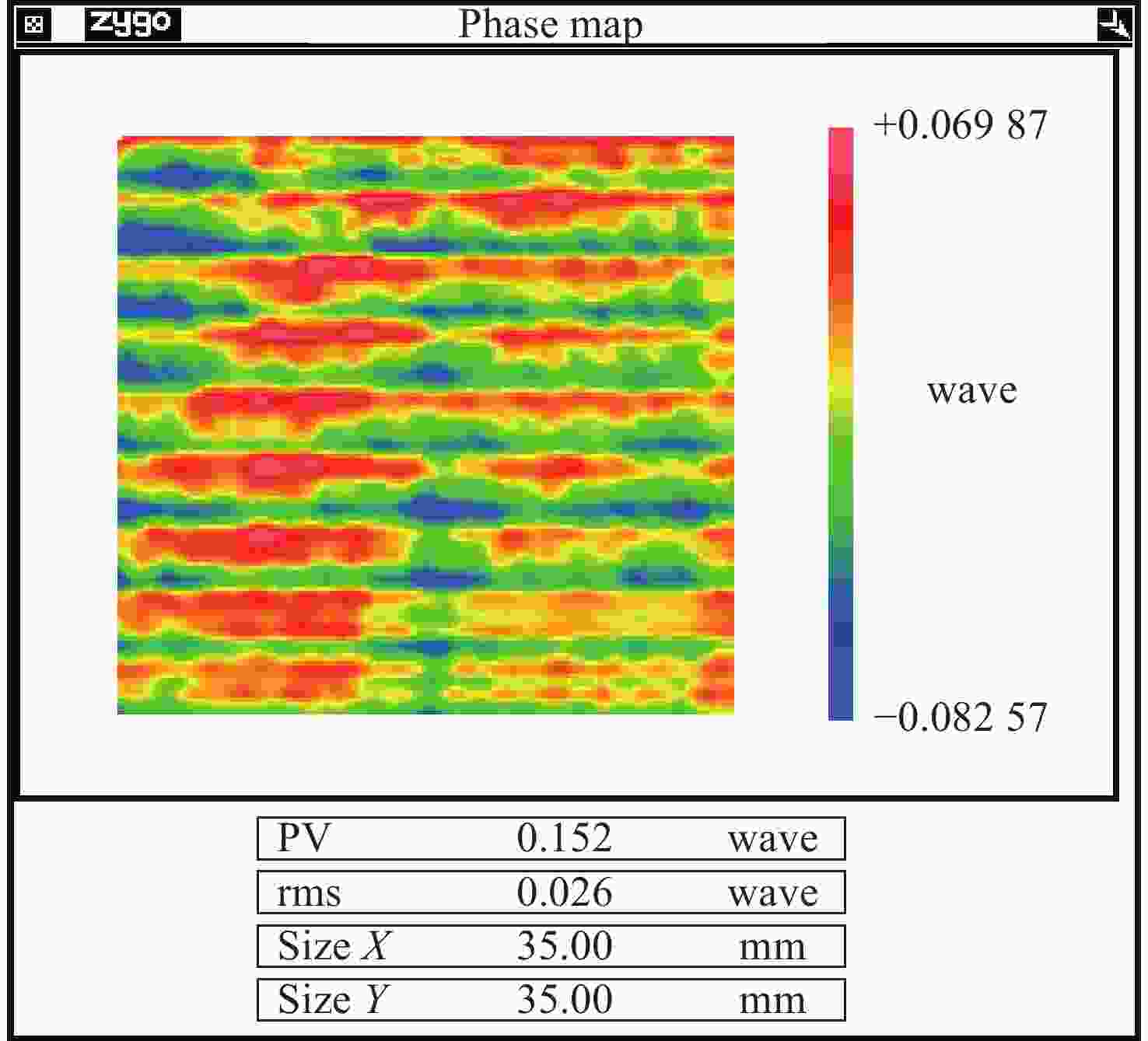

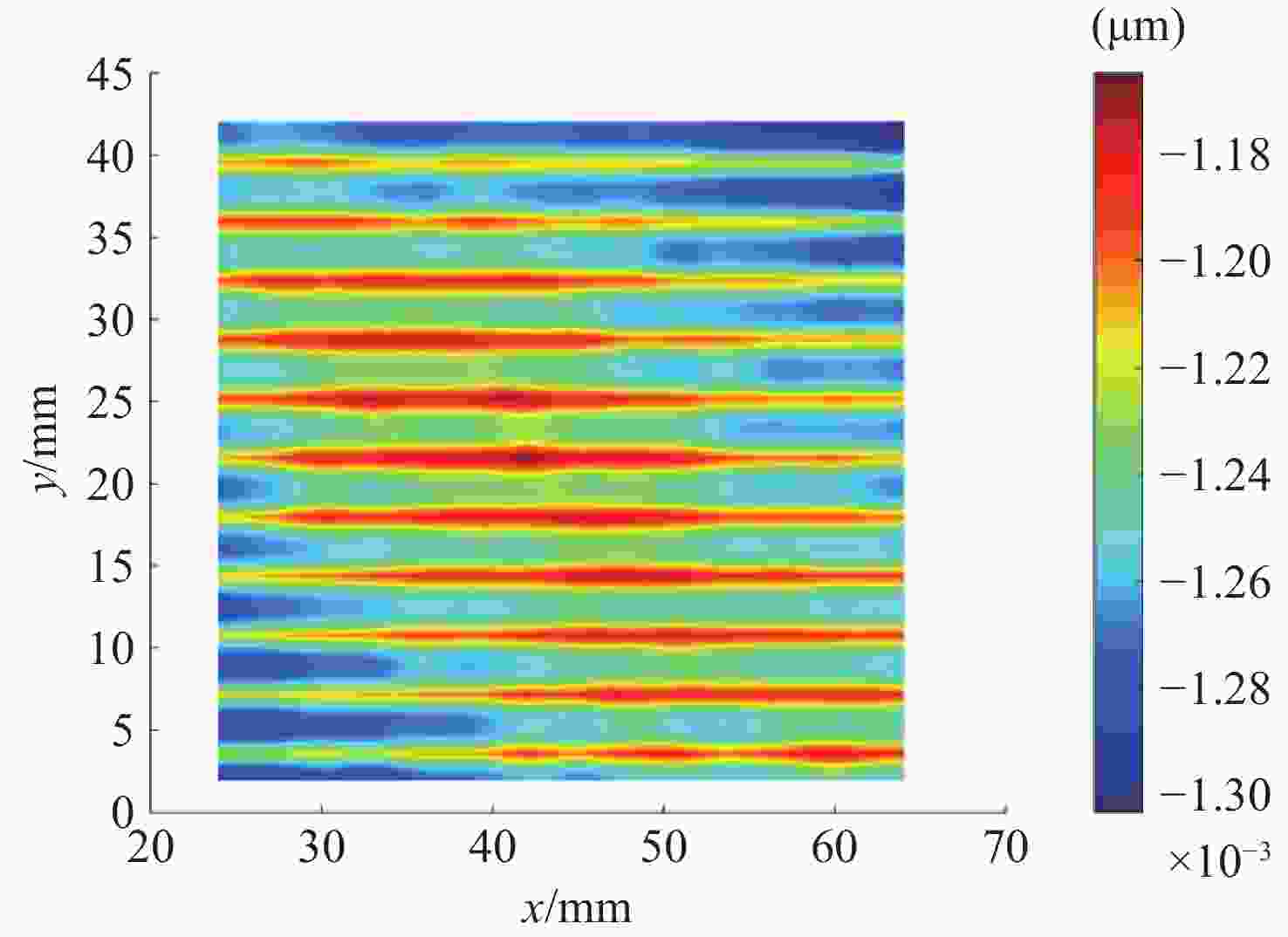

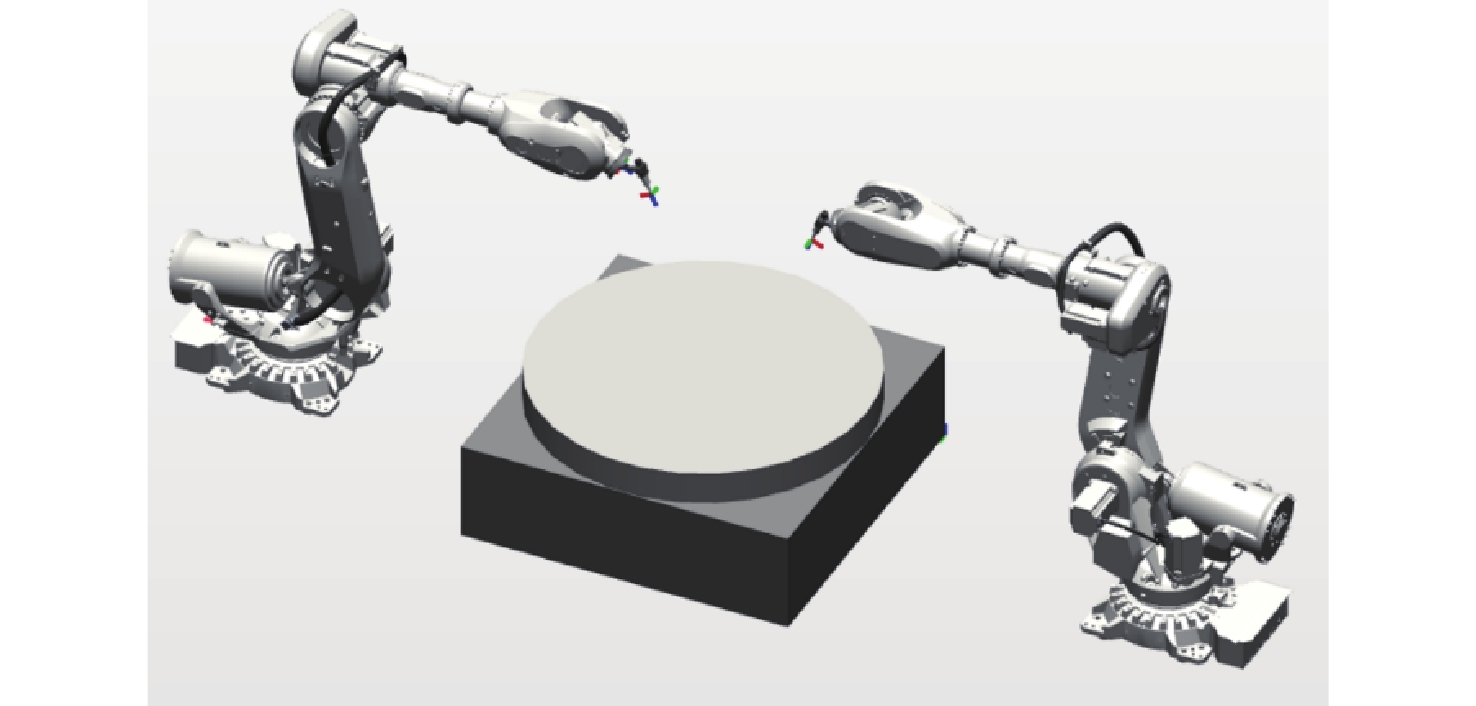

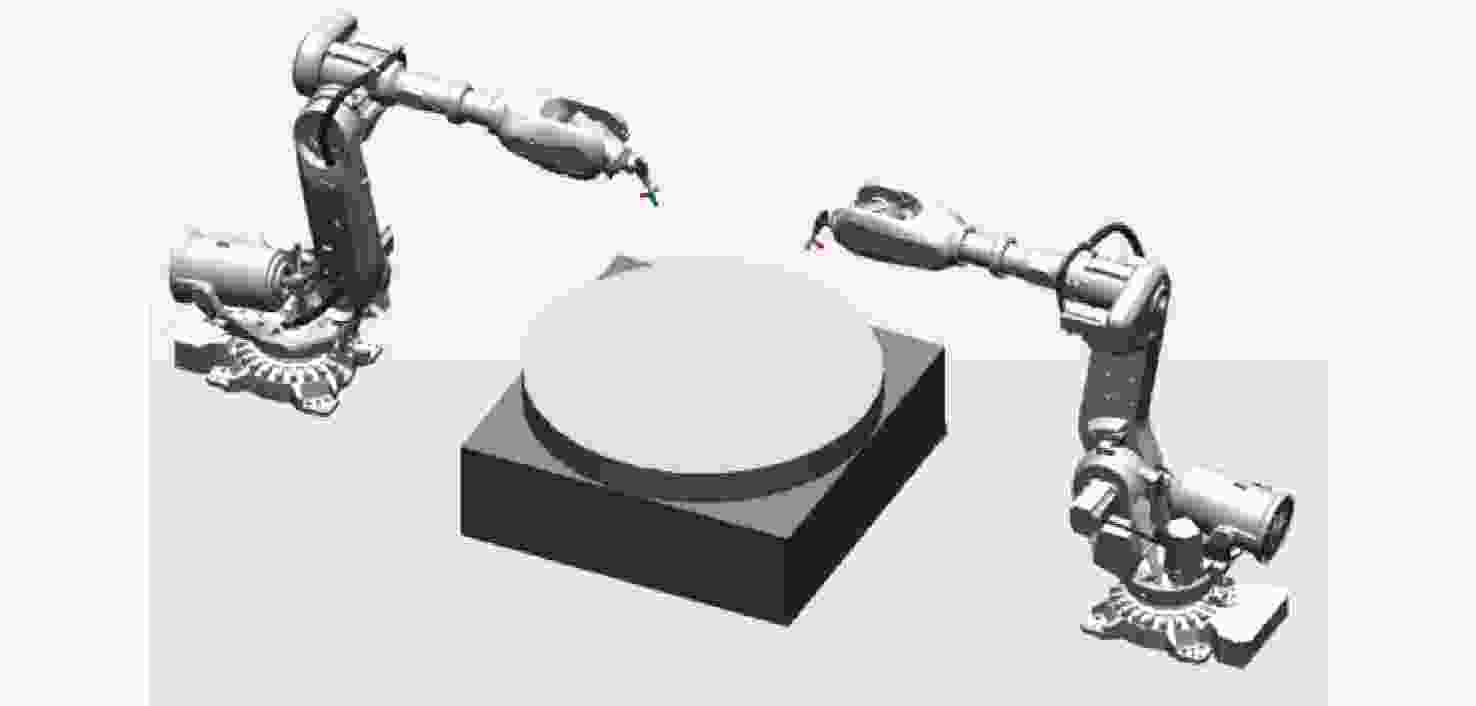

为了提升大口径光学元件的加工效率,提出了采用多个加工单元分别同时负载单个工具并共同执行加工任务,以降低加工单元执行时间从而大幅提升加工效率方法。首先,根据光学元件提出一种多机器人协同加工布局,接着,针对三种潜在的可行轨迹进行了模拟加工。然后,在离散仿真基础上,得出了轨迹参数的选取原则,针对离散仿真无法体现轨迹连续性对面形影响这一局限提出并建立了运动模式适配的积分去除函数模型,此模型将轨迹连续性的影响引入模拟加工中,最后提出一种协同加工避障策略并采用最优轨迹进行了协同加工的效率提升验证实验。实验结果表明:将初始面形PV=18.310λ(λ=632.8 nm),RMS为1.788λ的元件收敛至PV=4.873λ,RMS=1.113λ,与此同时其直径120 mm的有效区间内PV=4.661λ,RMS=0.857λ,经加工后收敛至PV=2.465λ,RMS=0.622λ。总执行时间为3.943h,若采用协同加工策略单个加工单元最长执行时间为2.041h,相比单工具效率提升1.93倍。与单机器人加工相比,该方法使得加工效率显著提高,面形精度得到保证,有效缩短了加工周期,在大孔径光学元件制造中具有很强的适用性和潜力,同时也为未来使用更多机器人的协同光学制造提供了轨迹规划策略参考和奠定了基础。

-

关键词:

- 多机器人协同光学加工 /

- 光学超精密制造 /

- 积分去除函数 /

- 轨迹规划 /

- 高效光学制造.

Abstract:To improve the processing efficiency of large-aperture optical components, a multi-robot, multi-tool collaborative processing method was proposed. A collaborative layout that has been tailored to the optical components was designed, and three feasible trajectories were simulated for analysis. The discrete simulation results were then used to establish principles for selecting trajectory parameters. To address the limitation of discrete simulation in capturing the influence of trajectory continuity on the surface map, an integral removal function model adapted to the motion mode was introduced. Furthermore, a collaborative machining obstacle avoidance strategy was developed. The experimental results obtained using the optimal trajectory demonstrated that with an initial surface shape of PV=18.310λ (λ=632.8 nm) and RMS=1.788λ, the final surface achieved PV=4.873λ and RMS=1.113λ. In addition, within the effective range of 120 mm diameter, PV=4.661 λ, RMS=0.857λ, converged to PV=2.465λ and RMS=0.622λ after processing. The total execution time was 3.943 hours, with the maximum execution time for a single processing unit being 2.041 hours, representing a 1.93-fold improvement over single-tool processing. This method significantly enhances processing efficiency, ensures surface shape accuracy, and holds great potential for the manufacturing of large-aperture optical components.

-

表 1 单机器人和多机器人协同加工耗时对比

Table 1. Comparison of the time consuming of single robot and multi-robot collaborative processing

轨迹种类 单机器人

加工时长协同加工

消耗时长协同加工

耗时占比光栅轨迹 3.562 h 1.788 h 50.20% 梳形轨迹 2.479 h 1.245 h 50.22% 组合轨迹 3.532 h 1.770 h 50.11% -

[1] STOCKMAN H S. James Webb space telescope[J]. Proceedings of the International Astronomical Union, 2006, 2: 522-523. doi: 10.1017/S1743921307011660 [2] NOGUCHI K, ANDO H, IZUMIURA H, et al. High-dispersion spectrograph (HDS) for SUBARU telescope[J]. Proceedings of SPIE, 1998, 3355: 354-362. doi: 10.1117/12.316771 [3] DINARDO F, TOMASI M, BURSI A, et al. Overview of the analysis and testing of a covering system for a telescope[C]. Proceedings of the 3rd International Symposium on Industrial Engineering and Automation, Springer, 2024: 216–224. [4] RANKA T, ASHBY D, CONAN R, et al. Performance analysis tools and results for GMT primary mirror segment active support system[J]. Proceedings of SPIE, 2018, 10705: 1070512. [5] DIERICKX P, ENARD D, MERKLE F, et al. 8.2 Metre primary mirrors of the VLT[J]. Proceedings of SPIE, 1990, 1271: 266-274. doi: 10.1117/12.20413 [6] ZHANG X J, HU H X, WANG X K, et al. Challenges and strategies in high-accuracy manufacturing of the world's largest SiC aspheric mirror[J]. Light: Science & Applications, 2022, 11(1): 310. [7] JOHNS M, MCCARTHY P, RAYBOULD K, et al. Giant Magellan telescope: overview[J]. Proceedings of SPIE, 2012, 8444: 84441H. [8] LIU ZH Y, LI L X, QI E H, et al. Fabrication of a 4 m SiC aspheric mirror using an optimized strategy of dividing an error map[J]. Photonics, 2024, 11(2): 125. doi: 10.3390/photonics11020125 [9] ZHOU J J, LI B, LI X N. Efficient full-aperture mirror polishing method with variable orbital radius in computer-controlled optical surfacing[J]. Optics Express, 2024, 32(13): 23865-23881. doi: 10.1364/OE.523657 [10] BAI Y, ZHANG ZH Y, LI L X, et al. High precision polishing of aluminum alloy mirrors through a combination of magnetorheological finishing and chemical mechanical polishing[J]. Optics Express, 2024, 32(9): 15813-15826. doi: 10.1364/OE.519369 [11] BAI Y, ZHANG X J, YANG CH, et al. Material removal model of magnetorheological finishing based on dense granular flow theory[J]. Light: Advanced Manufacturing, 2022, 3(4): 41. [12] WANG T Y, KE X L, HUANG L, et al. A comprehensive review of dwell time optimization methods in computer-controlled optical surfacing[J]. Light: Advanced Manufacturing, 2024, 5(3): 21. [13] 刘振宇, 李龙响, 曾雪峰, 等. 大口径非球面反射镜误差分离组合加工技术[J]. 光学 精密工程,2017,25(4):813-819. doi: 10.3788/OPE.20172504.0813LIU ZH Y, LI L X, ZENG X F, et al. Fabrication of large aspheric mirror using multi-mode polishing based on error separation[J]. Optics and Precision Engineering, 2017, 25(4): 813-819. (in Chinese). doi: 10.3788/OPE.20172504.0813 [14] KE X L, WANG T Y, CHOI H, et al. Dual-tool multiplexing model of parallel computer controlled optical surfacing[J]. Optics Letters, 2020, 45(23): 6426-6429. doi: 10.1364/OL.404575 [15] 姚永胜. 基于工业机器人的轮式抛光技术研究[D]. 西安: 中国科学院大学(中国科学院西安光学精密机械研究所), 2023.YAO Y SH. Research on technology of wheel polishing based on industrial robot[D]. Beijing: Xi’an Institute of Optics & Precision Mechanics, Chinese Academy of Sciences, 2023. (in Chinese). [16] 李龙响. 大口径非球面磁流变加工的关键技术研究[D]. 长春: 中国科学院研究生院(长春光学精密机械与物理研究所), 2016.LI L X. Study on the key techniques of magnetorheological finishing for large aspheric optics[D]. Changchun: Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences, 2016. (in Chinese). [17] WAN S L, WEI CH Y, HU CH, et al. Novel magic angle-step state and mechanism for restraining the path ripple of magnetorheological finishing[J]. International Journal of Machine Tools and Manufacture, 2021, 161: 103673. doi: 10.1016/j.ijmachtools.2020.103673 [18] LI H J, LI X Y, WAN S L, et al. High-efficiency smooth pseudo-random path planning for restraining the path ripple of robotic polishing[J]. Applied Optics, 2021, 60(25): 7732-7739. doi: 10.1364/AO.426616 [19] LIU X M, LI L X, LI X CH, et al. Tool mark prediction on the surface of large-aperture mirrors via magnetorheological finishing[J]. Optics Express, 2024, 32(7): 11150-11170. doi: 10.1364/OE.517342 -

下载:

下载: