-

摘要:

为了实现精密制造中关键部件残余应力的高精度检测,建立了电光调制椭偏应力传感系统,并对工程中常见的304不锈钢材料在单轴拉伸应力条件下的椭偏信号响应进行了研究。首先,基于反射椭偏的基本原理,建立了不同光轴方向上椭偏信号与单轴拉伸金属试样寻常折射率和异常折射率的关系。其次,针对不锈钢材料,优化了椭偏应力传感的工作点。通过对比消光点和非零线性工作点的椭偏信号,证明了非零线性条件适用于应力信号的传感。最后,对不同光轴方向下,由应力引起的椭偏信号进行测量。实验结果表明:针对304不锈钢,系统的最低应力检测限为7.84 kPa,系统的应力检测精度优于7.84 kPa。该系统可用于精密制造中,满足金属工件高精度应力检测的要求。

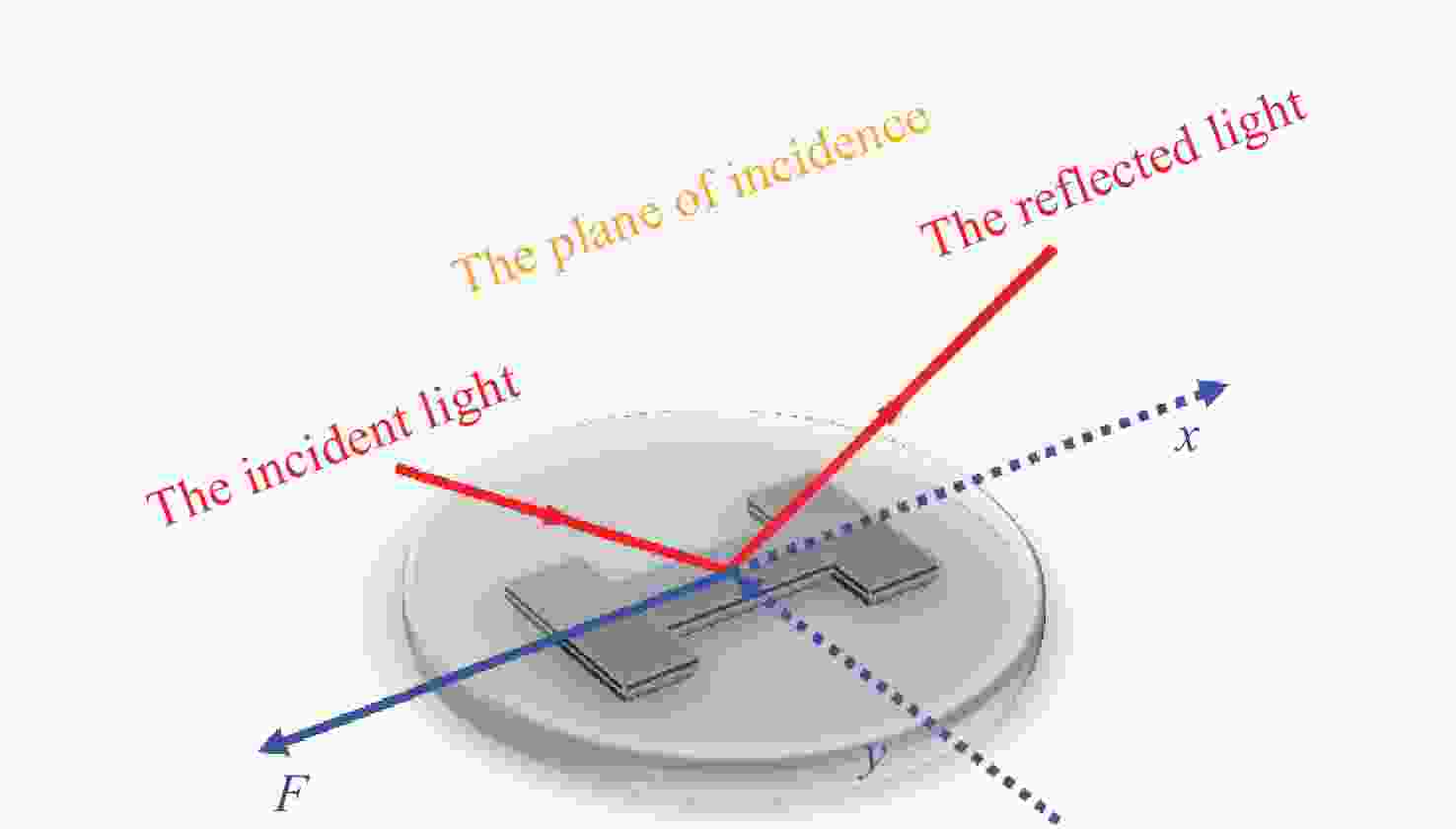

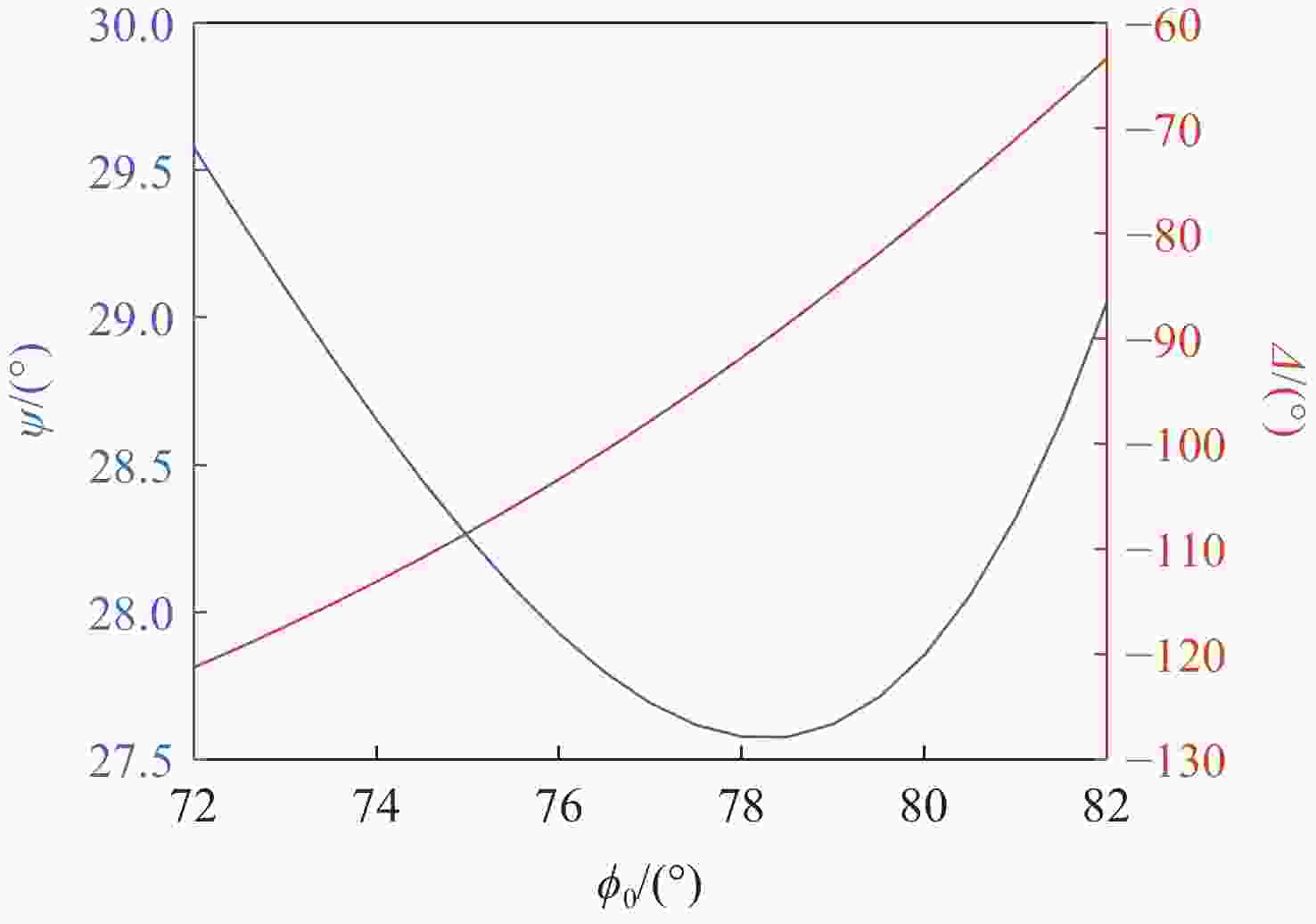

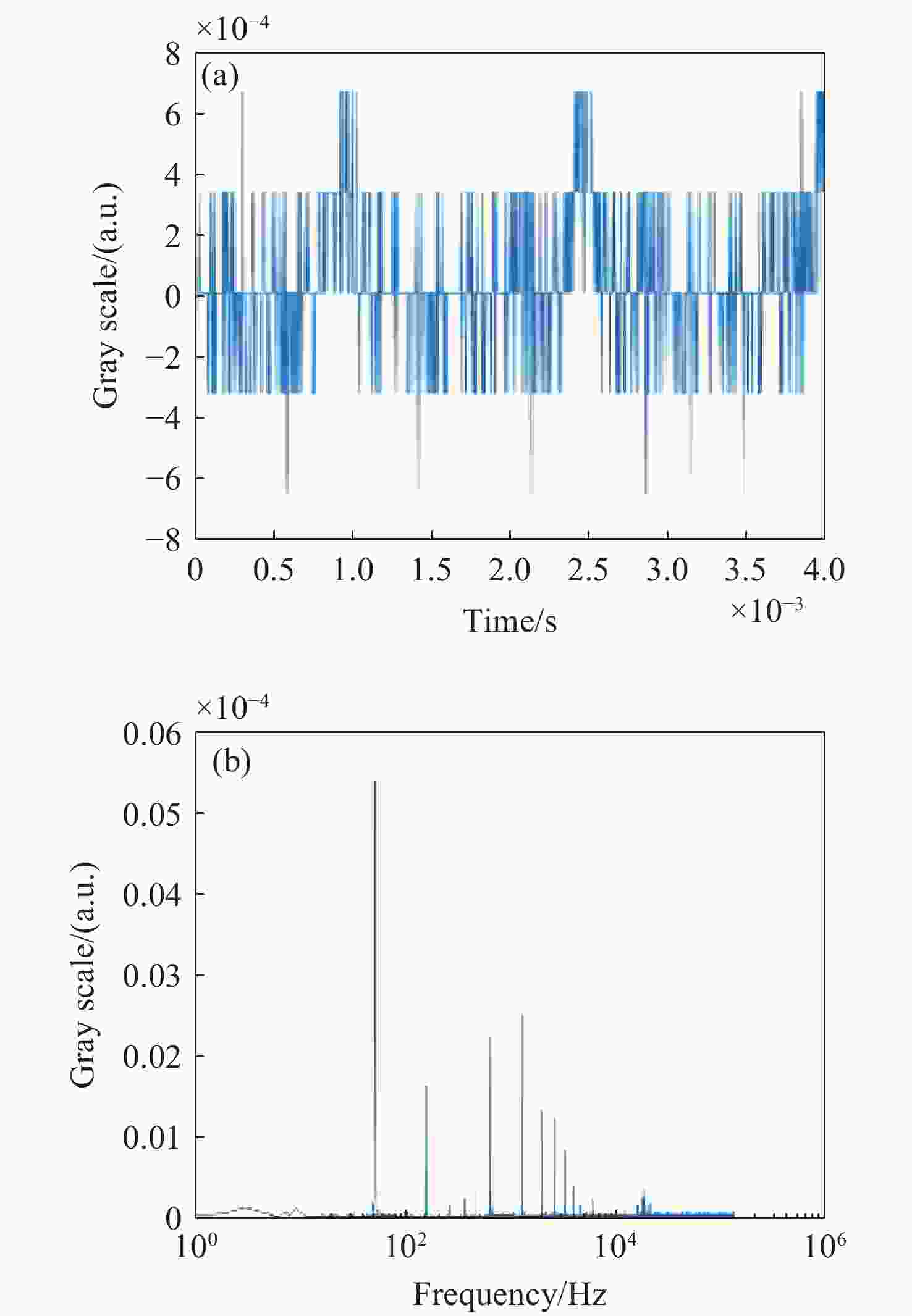

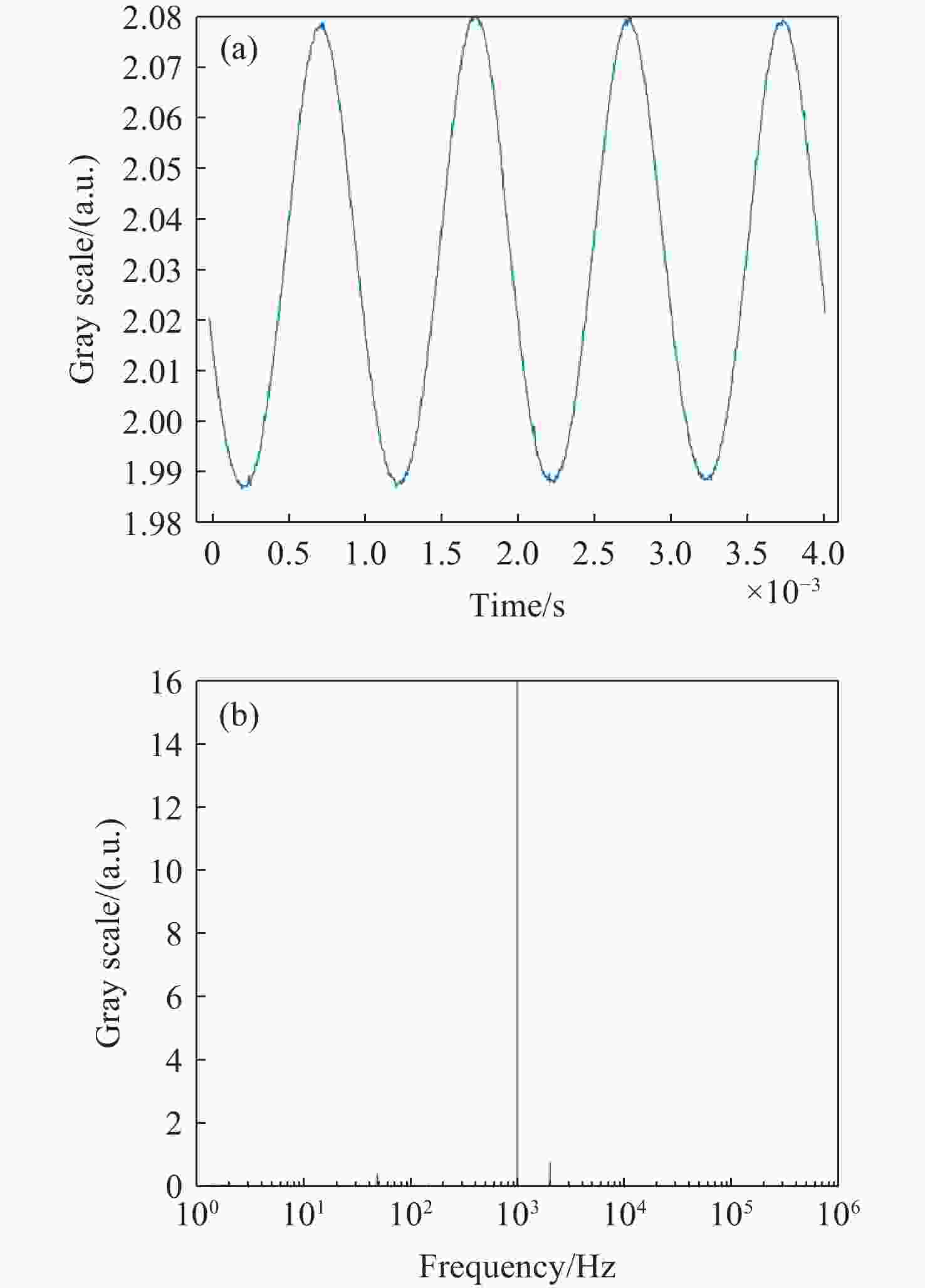

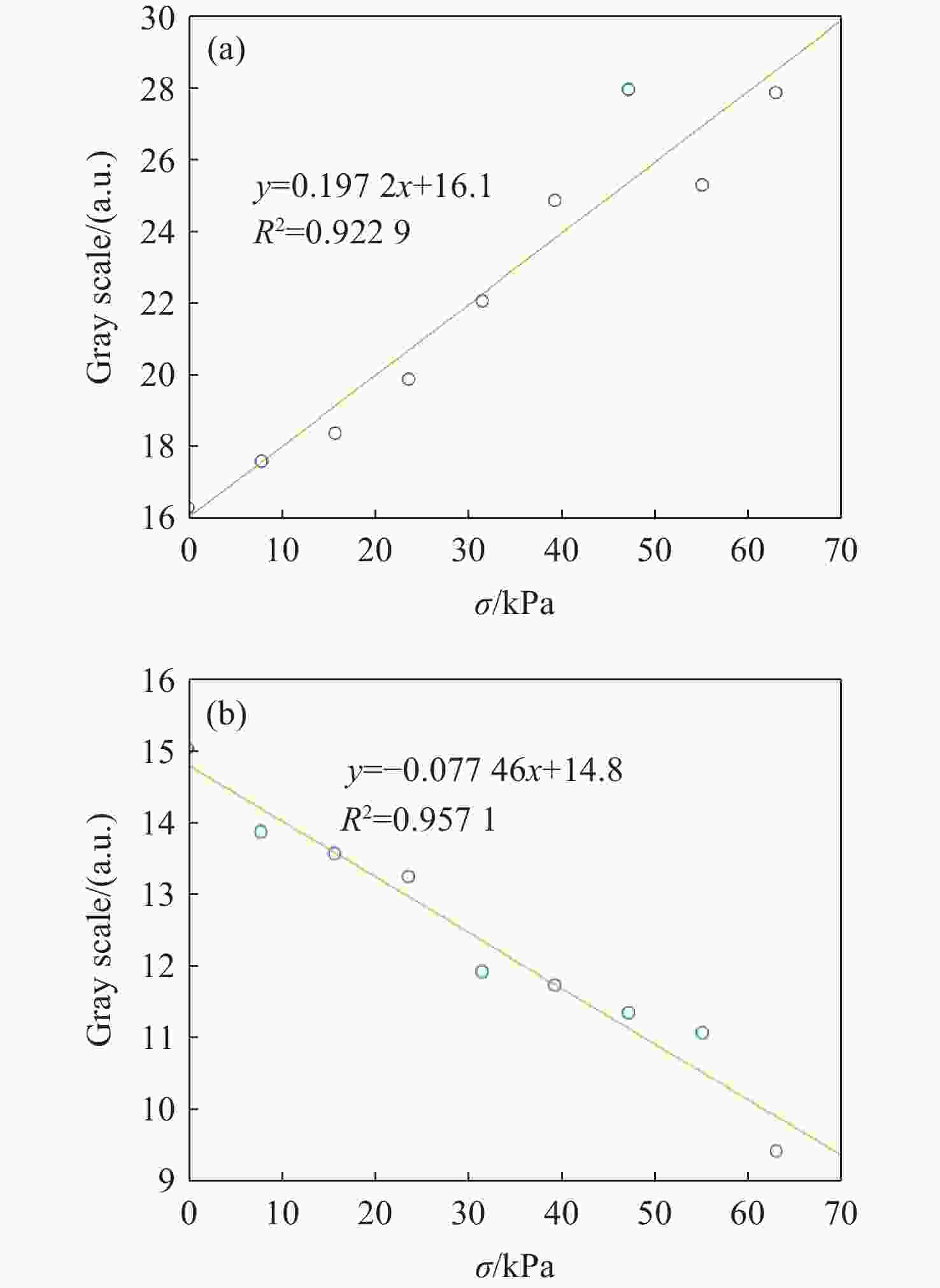

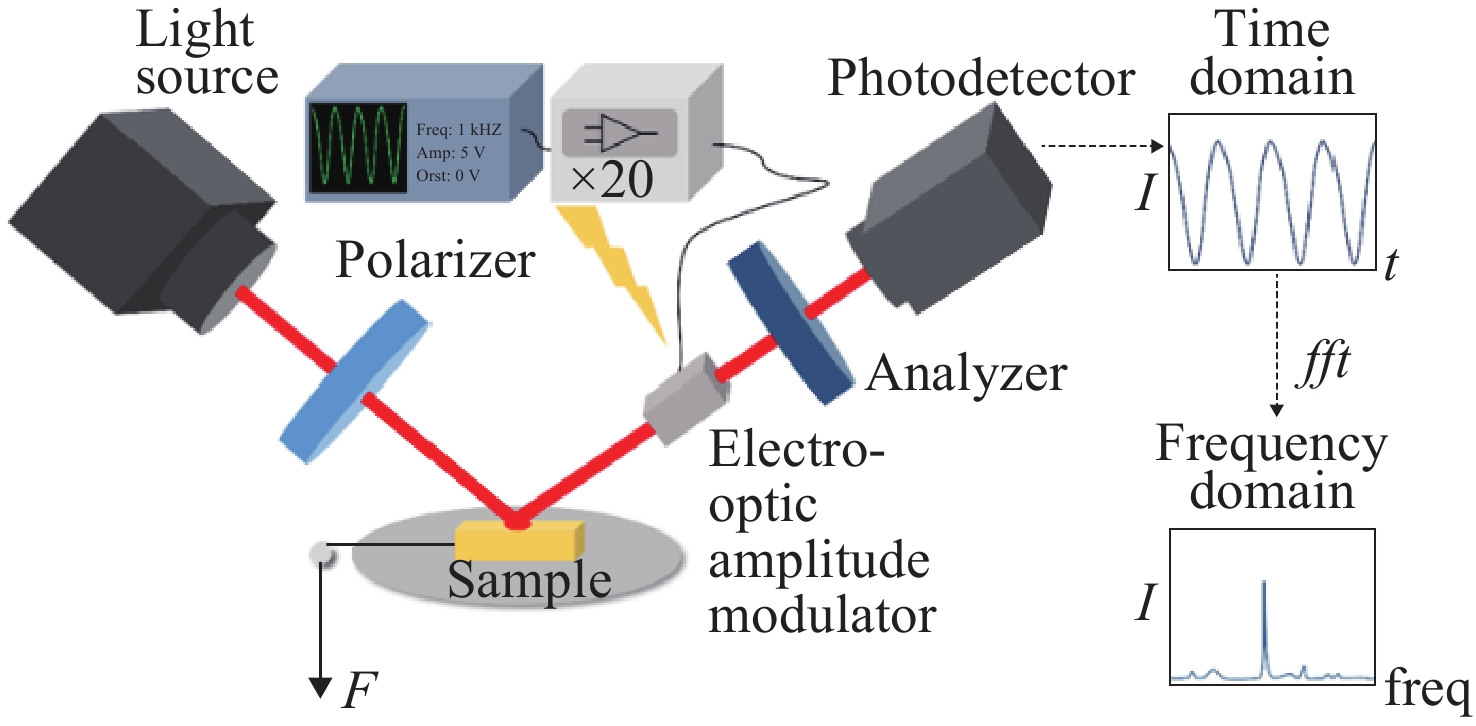

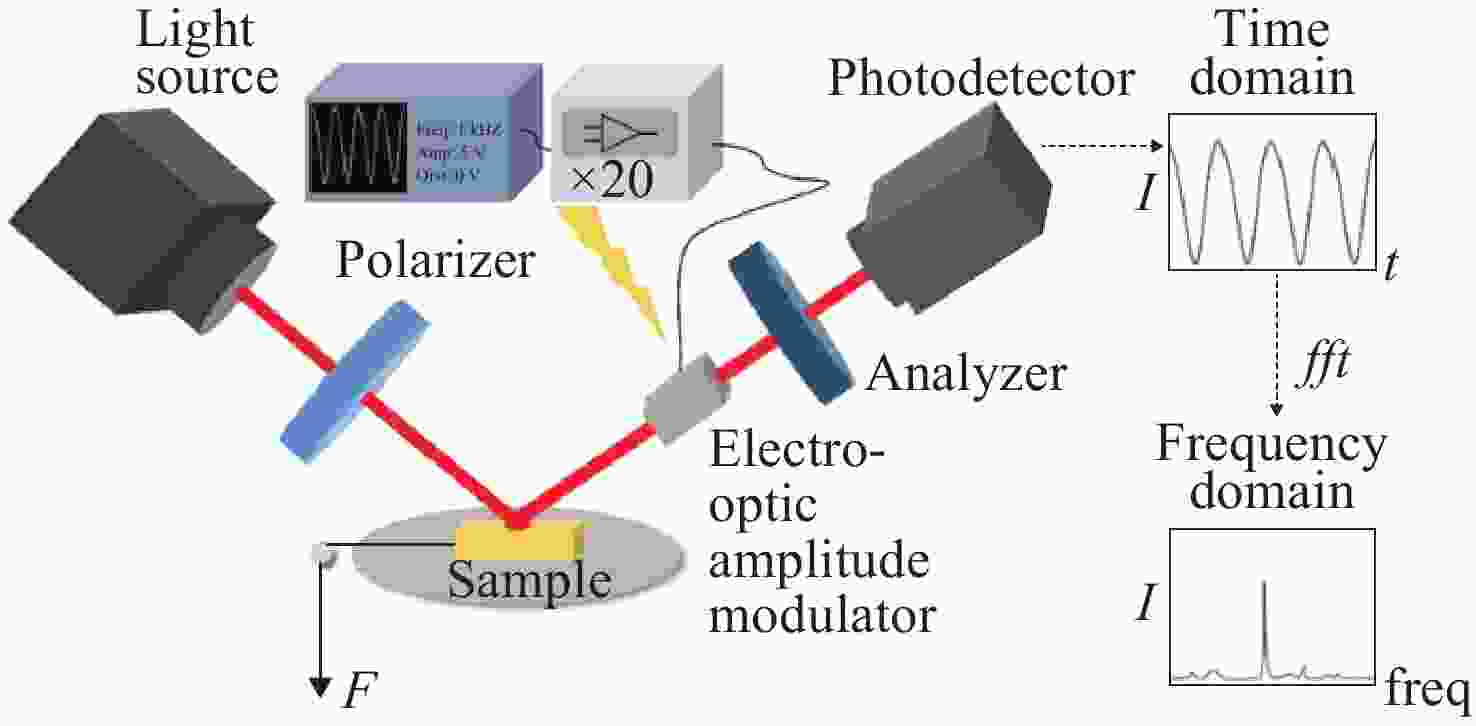

Abstract:To achieve high-precision residual stress detection in key components in precision manufacturing, an electro-optic modulated ellipsometric stress sensing system has been established. This study focused on the ellipsometric signal response of common 304 stainless-steel materials in engineering under uniaxial tensile stress conditions. Firstly, based on the fundamental principles of reflection ellipsometry, the relationship between the ellipsometric signal and the ordinary and extraordinary refractive indices was established for different optical axis directions. Secondly, the working point of ellipsometric stress sensing was optimized for stainless steel materials. By comparing the ellipsometric signals at the extinction point and the non-zero linear working point, it was demonstrated that the non-zero linear condition is suitable for stress signal sensing. Finally, the stress-induced ellipsometric signals were measured under different optical axis directions. The experimental results indicate that for 304 stainless steel, the system's minimum stress detection limit is 7.84 kPa, and the stress detection accuracy of the system is better than 7.84 kPa. This system can be utilized for high-precision stress detection requirements in metal workpieces in precision manufacturing.

-

Key words:

- photoelasticity /

- stress birefringence /

- ellipsometry /

- residual stress /

- electro-optic modulation

-

-

[1] 肖石磊, 李斌成. 光学元件残余应力无损检测技术概述[J]. 光电工程,2020,47(8):190068.XIAO SH L, LI B CH. Residual stress measurement methods of optics[J]. Opto-Electronic Engineering, 2020, 47(8): 190068. (in Chinese). [2] PEIXOTO C, VALENTIM P T, SOUSA P C, et al. Injection molding of high-precision optical lenses: A review[J]. Precision Engineering, 2022, 76: 29-51. [3] 马晓晖, 毛晶, 龙丽霞, 等. XRD测试材料表面微区残余应力[J]. 实验室科学,2022,25(2):10-13,18. doi: 10.3969/j.issn.1672-4305.2022.02.002MA X H, MAO J, LONG L X, et al. Measurement of residual stress in the micro-zone of the sample by X ray diffractometer[J]. Laboratory Science, 2022, 25(2): 10-13,18. (in Chinese). doi: 10.3969/j.issn.1672-4305.2022.02.002 [4] 许光, 邢力超, 张婷, 等. X射线衍射法测量高温合金波纹管残余应力[J]. 压力容器,2021,38(7):32-37. doi: 10.3969/j.issn.1001-4837.2021.07.005XU G, XING L CH, ZHANG T, et al. Measurement of residual stress in superalloy bellow using X-ray diffraction technology[J]. Pressure Vessel Technology, 2021, 38(7): 32-37. (in Chinese). doi: 10.3969/j.issn.1001-4837.2021.07.005 [5] 包亦望, 马德隆. 陶瓷涂层的残余应力评价及其尺寸效应[J]. 硅酸盐学报,2019,47(8):1033-1038.BAO Y W, MA D L. Evaluation of residual stress in ceramic coatings and its size effects[J]. Journal of the Chinese Ceramic Society, 2019, 47(8): 1033-1038. (in Chinese). [6] 刘明智, 梁康, 熊巍, 等. 沉积参数对磁控溅射镀金膜膜层残余应力与微观形貌的影响[J]. 导航与控制,2020,19(6):98-104,73. doi: 10.3969/j.issn.1674-5558.2020.06.013LIU M ZH, LIANG K, XIONG W, et al. Effect of deposition parameters on residual stress and microstructure in magnetron sputtering Au thin films[J]. Navigation and Control, 2020, 19(6): 98-104,73. (in Chinese). doi: 10.3969/j.issn.1674-5558.2020.06.013 [7] 郑锦华, 李志雄, 刘青云, 等. 负偏压对高界面强度类金刚石薄膜制备的影响[J]. 材料工程,2023,51(10):93-100. doi: 10.11868/j.issn.1001-4381.2022.001081ZHENG J H, LI ZH X, LIU Q Y, et al. Effect of negative bias voltage on preparation of diamond-like carbon films with high interfacial strength[J]. Journal of Materials Engineering, 2023, 51(10): 93-100. (in Chinese). doi: 10.11868/j.issn.1001-4381.2022.001081 [8] KAJIHARA Y, TAKAHASHI R, YOSHIDA I, et al. Measurement method of internal residual stress in plastic parts using terahertz spectroscopy[J]. Nanomanufacturing and Metrology, 2021, 4(1): 46-52. [9] FARAHANI B V, DIREITO F, SOUSA P J, et al. Electronic Speckle Pattern Interferometry for fatigue crack monitoring[J]. Procedia Structural Integrity, 2022, 37: 873-879. doi: 10.1016/j.prostr.2022.02.021 [10] YADAV N, WACHTARCZYK K, GĄSIOR P, et al. In-line residual strain monitoring for thermoplastic automated tape layup using fiber Bragg grating sensors[J]. Polymer Composites, 2022, 43(3): 1590-1602. doi: 10.1002/pc.26480 [11] 李克武, 王爽, 刘梓良, 等. 双弹光级联的差频调制型应力双折射测量[J]. 光学学报,2023,43(4):0412001. doi: 10.3788/AOS221495LI K W, WANG SH, LIU Z L, et al. Stress birefringence measurement based on double cascaded photoelastic modulation with differential frequencies[J]. Acta Optica Sinica, 2023, 43(4): 0412001. (in Chinese). doi: 10.3788/AOS221495 [12] 张伟, 杨林, 刘灿. 一种基于光弹调制器的应力双折射测量方法[J]. 光学与光电技术,2021,19(2):64-69.ZHANG W, YANG L, LIU C. A stress birefringence measurement method based on photoelastic modulator[J]. Optics & Optoelectronic Technology, 2021, 19(2): 64-69. (in Chinese). [13] WANG CH Y, LIU W, NIU Y, et al. Using the reflection ellipsometry to detect the stress for the gold coating reflection mirrors[J]. Microgravity Science and Technology, 2022, 34(5): 98. [14] AZZAM R M A, BASHARA N M, BALLARD S S. Ellipsometry and polarized light[J]. Physics Today, 1978, 31(11): 72. [15] ARWIN H, WELIN-KLINTSTRÖM S, JANSSON R. Off-null ellipsometry revisited: basic considerations for measuring surface concentrations at solid/liquid interfaces[J]. Journal of Colloid and Interface Science, 1993, 156(2): 377-382. doi: 10.1006/jcis.1993.1125 [16] JIN X N, WANG CH Y, SHEN J, et al. Linear off null working condition for total internal reflection imaging ellipsometry to detect subtle electron density change[J]. Proceedings of SPIE, 2020, 11781: 117811I. -

下载:

下载: