-

摘要:

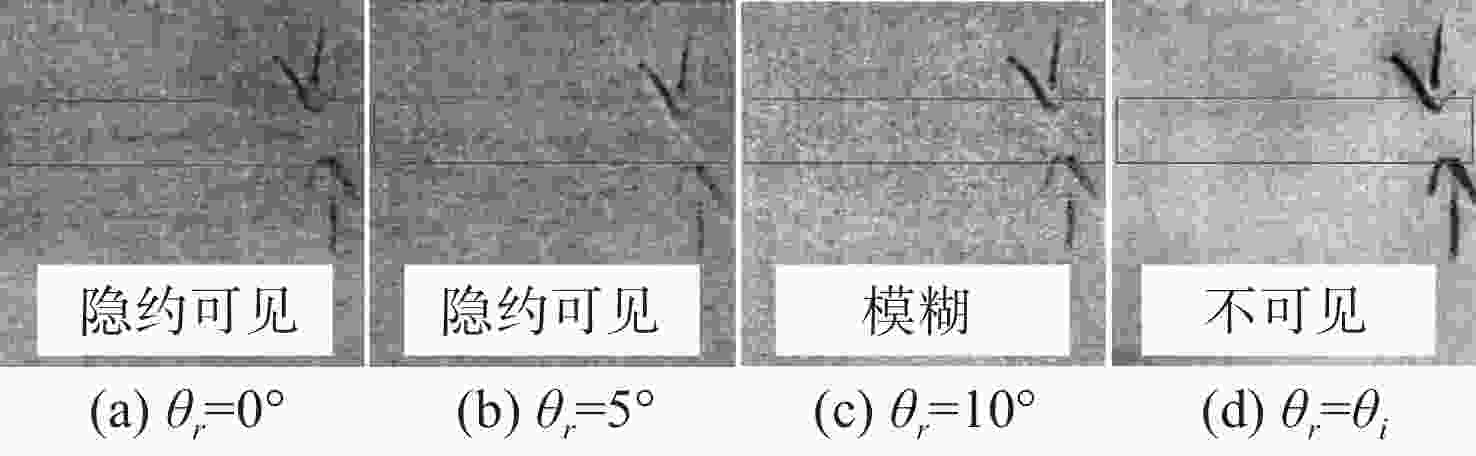

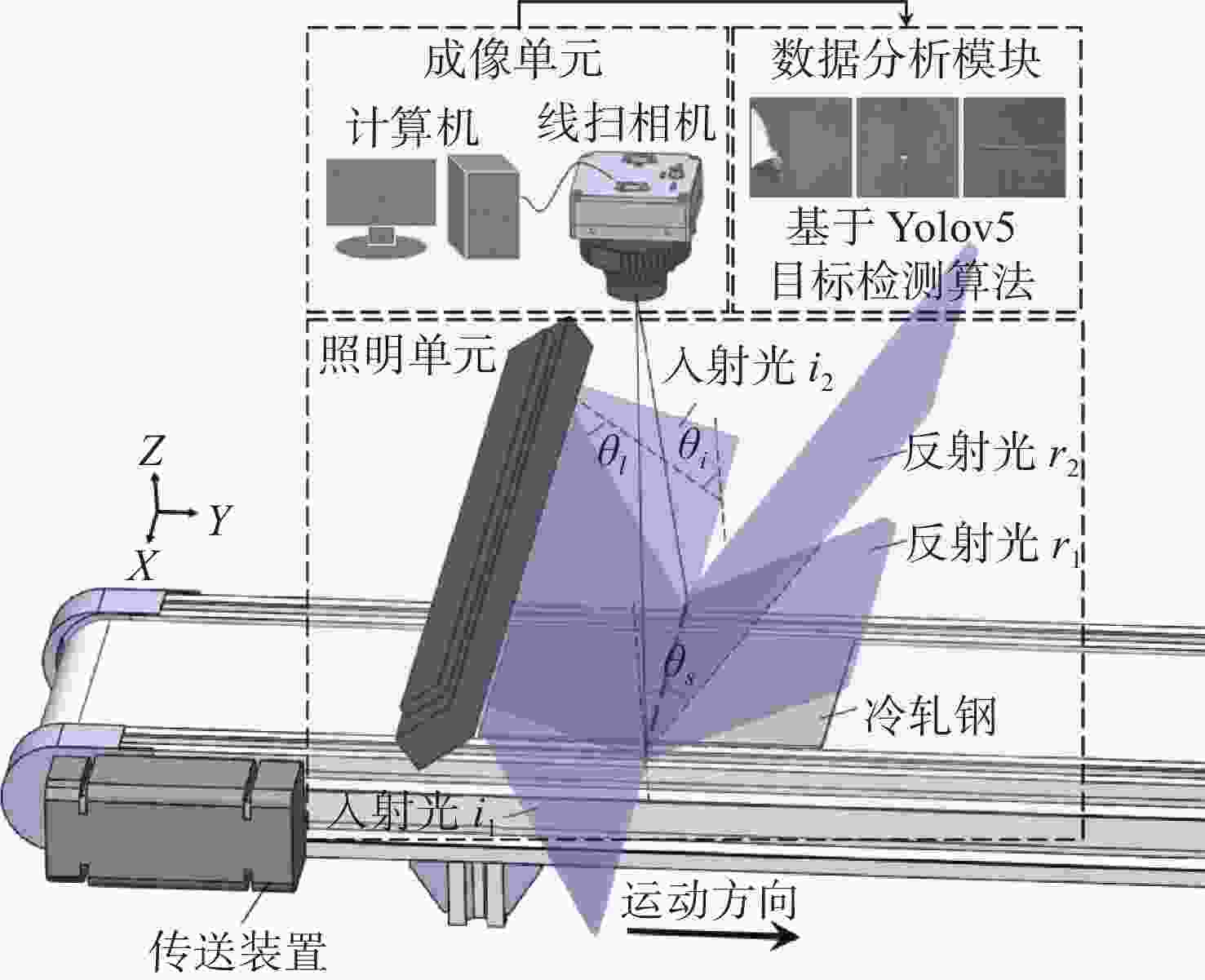

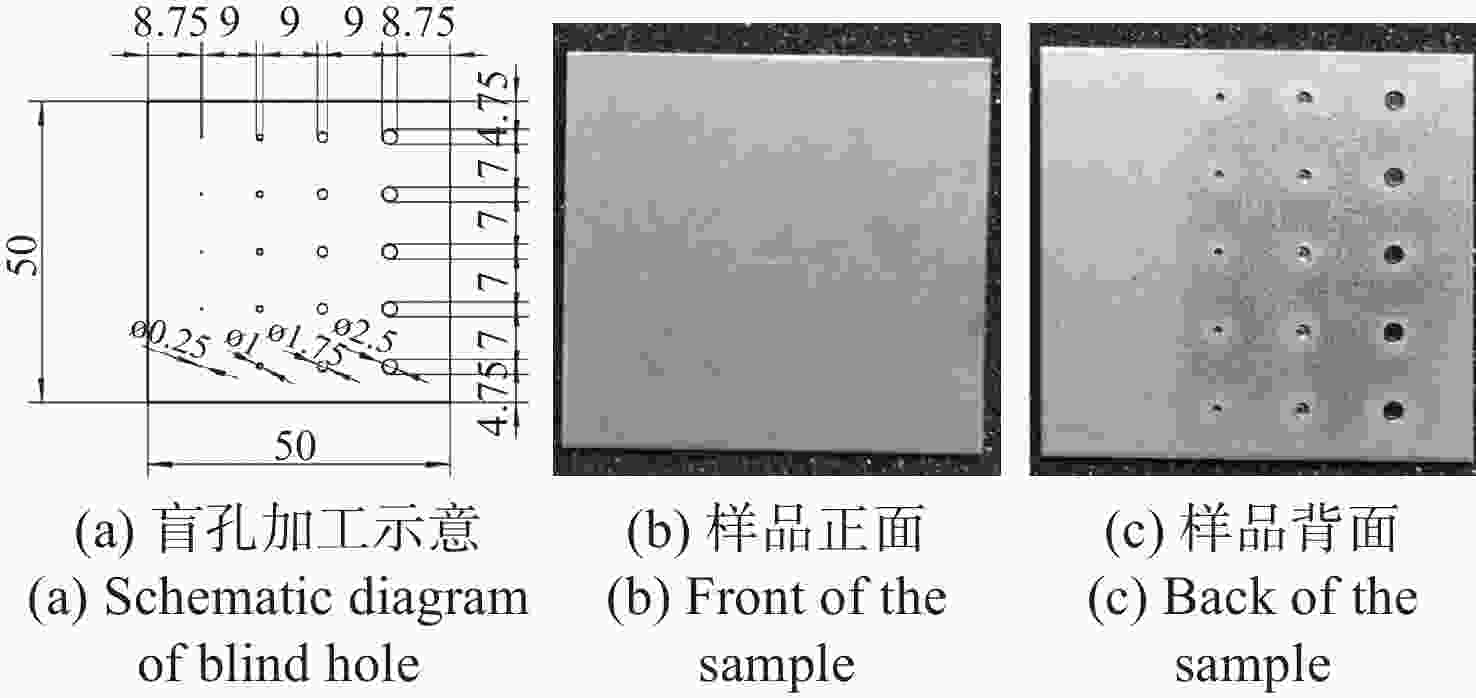

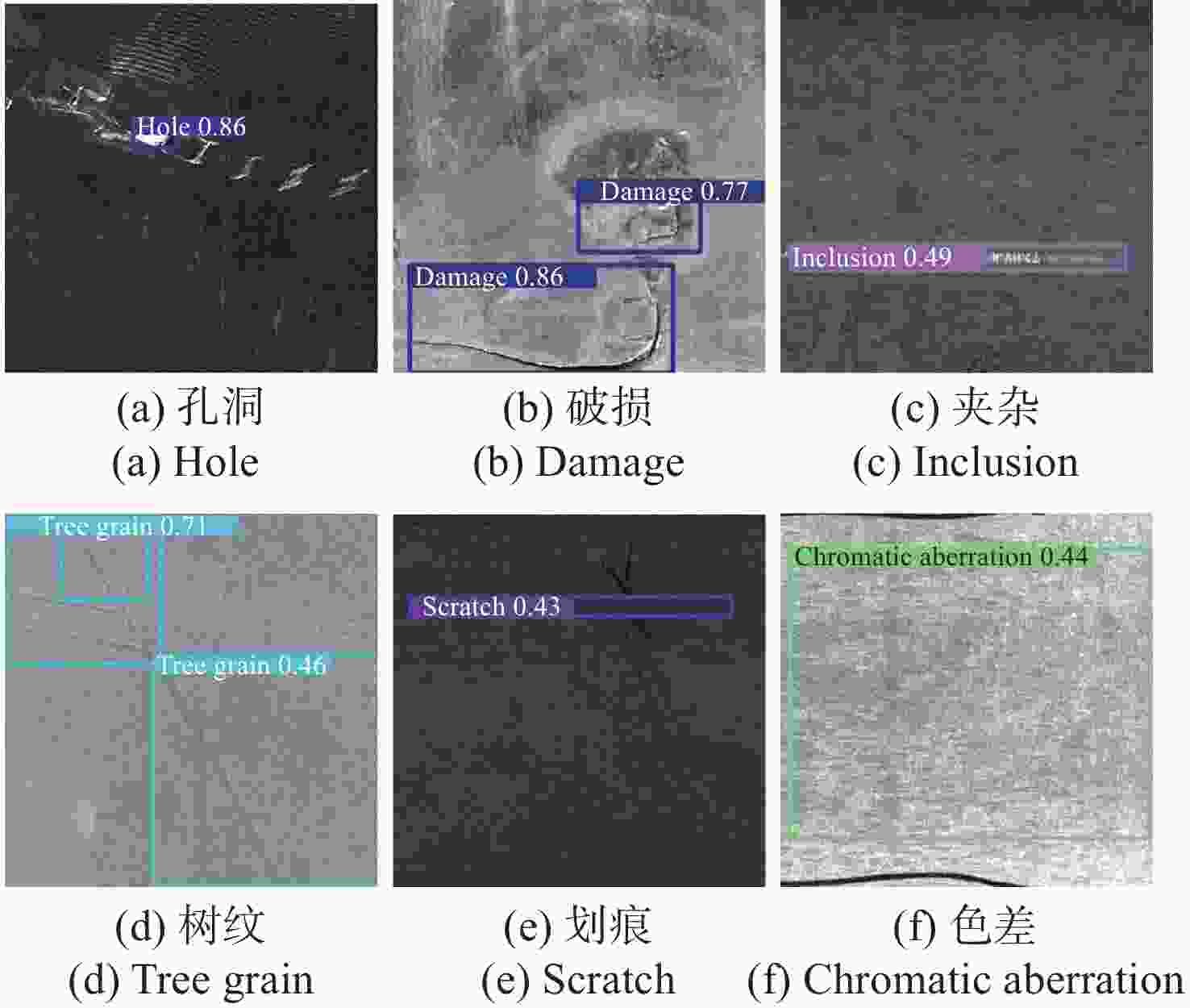

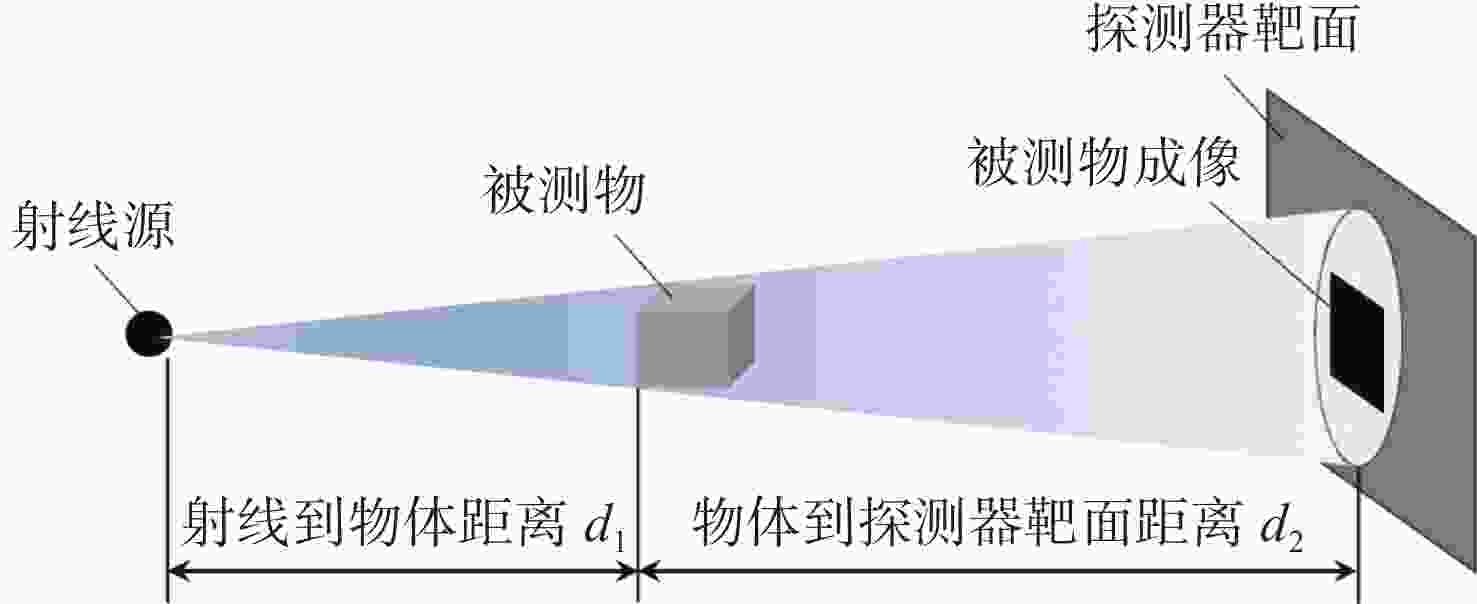

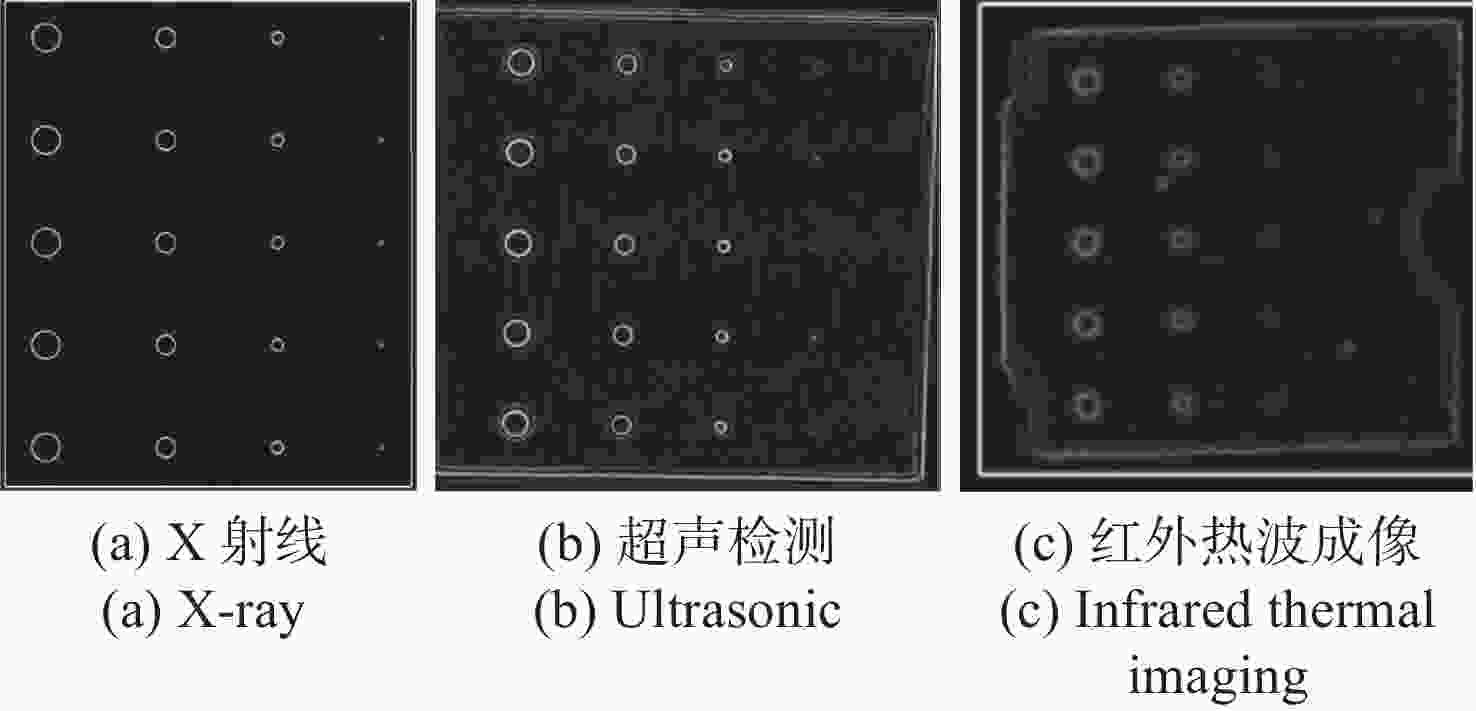

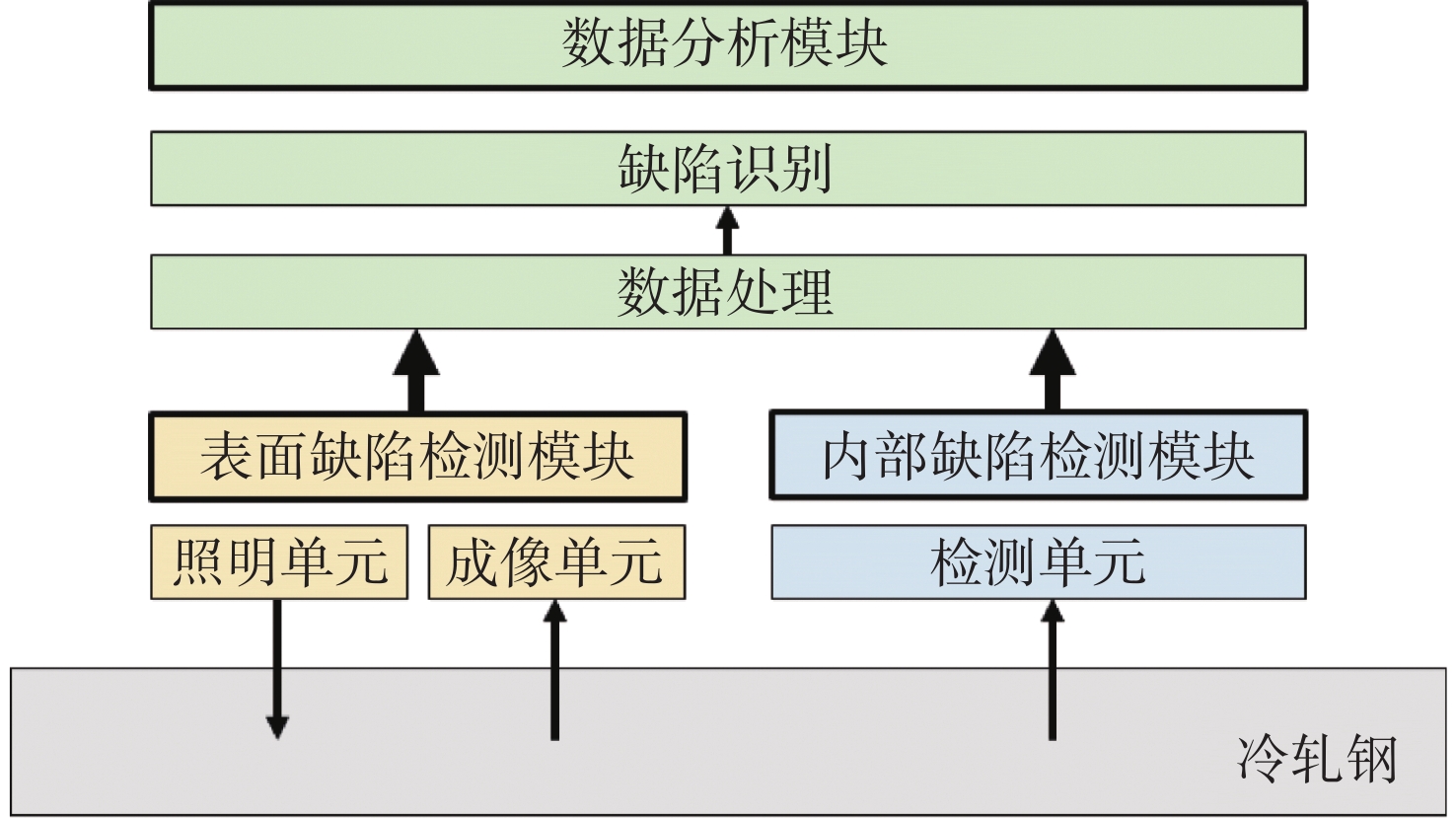

为实现冷轧钢缺陷的全面检测,针对其表面和内部缺陷检测展开研究。对于表面缺陷检测,提出采用双侧线光源照明方案,并与常规线光源照明方案进行对比。对于内部缺陷检测,从检测分辨率和缺陷边缘特征两方面分析X射线、超声以及红外热波成像等金属内部检测技术的适用性。经实验验证,双侧线光源照明不仅可以使YOLOv5目标检测算法总体平均精度mAP:0.5达到90.16%,相比线光源照明提升了15.46%,还可优化模型分类和提高训练效率。X射线和超声波检测法可检测直径为0.25 mm的盲孔,而红外热波成像技术则可有效识别出直径为1 mm的盲孔。在缺陷边缘特征评估中,X射线检测法的最小盲孔边缘灰度差值为145,超声波为89,红外热波成像为30。本研究提出了一种冷轧钢表面缺陷检测的改进方案,并为内部缺陷检测提供了思路。

Abstract:This paper focuses on the comprehensive detection of defects in cold rolled steel through examination for surface and internal defects. Regarding surface defect detection, a bilateral line light illumination scheme is proposed and a comparison with line light illumination scheme is carried out. As for internal defect detection, the applicability of various metal internal inspection technologies such as X-ray, ultrasound, and infrared thermography is analyzed from the perspectives of detection resolution and defect edge characteristics. The results show that bilateral line light illumination not only increases the overall average precision of the YOLOv5 object detection algorithm model to 90.16% (an increase of 15.46% compared to the line light illumination) but also improves model classification and training efficiency. X-ray and ultrasound inspection technologies can detect blind holes with a diameter of 0.25 mm, while infrared thermography can detect blind holes with a diameter of 1 mm. In evaluating defect edge characteristics, X-ray inspection technology exhibits a minimum blind hole edge grayscale difference of 145, ultrasound of 89, and infrared thermography of 30. This study proposes an improved scheme for the detection of surface defects in cold rolled steel and offers insights for the research on internal defect detection.

-

表 1 冷轧钢样品缺陷尺寸

Table 1. Defect size in cold rolled steel samples

缺陷类型 长度均值/cm 不确定度 宽度均值/cm 不确定度 孔洞 0.896 0.035 0.512 0.020 破损 4.960 0.025 1.204 0.030 夹杂 15.52 0.74 0.162 0.091 树纹 8.242 0.030 0.200 0.025 划痕 20.49 0.74 0.0222 0.0084 色差 19.70 0.74 5.994 0.030 表 2 白光线光源与白光双侧线光源之间的对比

Table 2. Imaging comparison when using white lateral and white bilateral line light source illuminations

孔洞 破损 夹杂 树纹 纵向划痕 横向划痕 色差 白光

单侧线光源

白光

双侧线光源

表 3 白光线光源与白光双侧线光源照明下YOLOv5目标检测算法结果

Table 3. Results of YOLOv5 target detection algorithm using white line light source and white bilateral line light source illuminations

白光线光源 白光双侧线光源 准确率 80.80% 91.50%↑ 召回率 96.00% 97.67%↑ mAP:0.5 74.70% 90.16%↑ 损失值 1.38% 1.37% 孔洞 99.50% 99.50% 破损 99.60% 99.60% 夹杂 74.80% 89.80%↑ 树纹 74.60% 96.27%↑ 划痕 65.57% 83.90%↑ 色差 \ 73.00% 表 4 Sobel算法盲孔样品边缘特征提取结果

Table 4. Results of edge detection on blind hole sample by applying the Sobel algorithm

工业CT 超声检测 红外热波成像 盲孔检出数 20 20 15 盲孔边缘连通数 20 19 13 边缘提取准确数 20 19 10 最大盲孔边缘灰度差值 φ2.50 mm 190 193 104 φ1.75 mm 187 180 80 φ1.00 mm 184 172 30 φ0.25 mm 145 89 / -

[1] LI ZH, LI ZH, HUANG H, et al. Green lithium: photoelectrochemical extraction[J]. PhotoniX, 2023, 4(1): 23. [2] ZHU Y N, LUO H, YANG CH Y, et al. Color-preserving passive radiative cooling for an actively temperature-regulated enclosure[J]. Light: Science & Applications, 2022, 11(1): 122. [3] 李玮. 用于锂离子电池钢壳的镀镍钴钢带制备工艺及耐蚀性研究[D]. 湘潭: 湘潭大学, 2011.LI W. The study of preparation and corrosion resistance of cobalt-nickel-plated steel strip for lithium-ion battery shell[D]. Xiangtan: Xiangtan University, 2011. (in Chinese). [4] 赵小龙, 王雄, 罗晓阳, 等. 退火温度对CSP冷轧低碳高强钢带组织和性能的影响[J]. 金属热处理,2021,46(1):43-49.ZHAO X L, WANG X, LUO X Y, et al. Effect of annealing temperature on microstructure and properties of cold rolled low carbon high strength sheet by CSP[J]. Heat Treatment of Metals, 2021, 46(1): 43-49. (in Chinese). [5] MANCINI E, CAMPANA F, SASSO M, et al. Effects of cold rolling process variables on final surface quality of stainless steel thin strip[J]. The International Journal of Advanced Manufacturing Technology, 2012, 61(1-4): 63-72. [6] 董双鹏, 宋进英, 陈业熊, 等. 冷轧钢板表面缺陷的种类及形成原因[J]. 机械工程材料,2012,36(7):100-104.DONG SH P, SONG J Y, CHEN Y X, et al. Types and forming reasons of cold rolled steel plate surface defects[J]. Materials for Mechanical Engineering, 2012, 36(7): 100-104. (in Chinese). [7] 胡华东, 王乐, 汤化胜, 等. 冷轧宽厚规格深冲钢梗印缺陷成因分析及其控制措施[J]. 轧钢,2022,39(2):124-128.HU H D, WANG L, TANG H SH, et al. Cause analysis of stem seal defects of cold rolled wide and thick gauge deep drawing steel strip and its control measures[J]. Steel Rolling, 2022, 39(2): 124-128. (in Chinese). [8] 王畅, 于洋, 王林, 等. 冷轧双相钢镀锌条带状色差缺陷产生原因及机理研究[J]. 轧钢,2023,40(1):52-58.WANG CH, YU Y, WANG L, et al. Study on the cause and mechanism of the strip color difference defects of cold rolled dual- phase steel galvanized strip[J]. Steel Rolling, 2023, 40(1): 52-58. (in Chinese). [9] SURESH B R, FUNDAKOWSKI R A, LEVITT T S, et al. A real-time automated visual inspection system for hot steel slabs[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 1983, PAMI-5(6): 563-572. [10] NATH V, CHATTOPADHYAY C, DESAI K A. On enhancing prediction abilities of vision-based metallic surface defect classification through adversarial training[J]. Engineering Applications of Artificial Intelligence, 2023, 117: 105553. [11] 杨水山, 何永辉, 王康健. 高速冷连轧带钢表面质量在线检测系统开发与应用[J]. 世界钢铁,2013,13(3):62-67. doi: 10.3969/j.issn.1672-9587.2013.03.011YANG SH SH, HE Y H, WANG K J. Development on on-line inspection system for high speed strip surface quality at cold continuous rolling mill[J]. World Iron & Steel, 2013, 13(3): 62-67. (in Chinese). doi: 10.3969/j.issn.1672-9587.2013.03.011 [12] 沈春光, 李虎威, 荆涛, 等. 基于深度学习的带钢表面缺陷检测在小样本数据集的应用[J]. 轧钢,2022,39(2):82-86.SHEN CH G, LI H W, JING T, et al. Application of deep learning-based surface defect recognition of plate in small sample dataset[J]. Steel Rolling, 2022, 39(2): 82-86. (in Chinese). [13] JUNet A, MESSAGER A, WECK A, et al. Internal fatigue crack propagation in a Ti-6Al-4V alloy: an in situ study[J]. International Journal of Fatigue, 2023, 168: 107450. [14] YANG Q ZH, ZHAO Y, HU X A, et al. Small crack propagation and closure behaviours and mechanisms in a powder metallurgy superalloy at high temperature in air[J]. International Journal of Fatigue, 2023, 175: 107797. [15] 白贇沨, 刘祎, 张小琳, 等. 基于GF-WLS和VSM的多能量X射线图像融合方法[J]. 无损检测,2022,44(9):34-41,74. doi: 10.11973/wsjc202209007BAI Y F, LIU Y, ZHANG X L, et al. Multi energy X-ray image fusion method based on GF-WLS and VSM[J]. Nondestructive Testing, 2022, 44(9): 34-41,74. (in Chinese). doi: 10.11973/wsjc202209007 [16] TAKADA H, TOMURA Y, ARATANI M, et al. On-line detection system for internal flaws in as-hot-rolled steel strip using ultrasonic probe array[J]. Materials Transactions, 2011, 52(3): 531-538. [17] 张永生, 黄松岭, 赵伟, 等. 基于电磁超声的钢板裂纹检测系统[J]. 无损检测,2009,31(4):307-310.ZHANG Y SH, HUANG S L, ZHAO W, et al. Detection system about steel cracks based on electronic ultrasonic[J]. Nondestructive Testing, 2009, 31(4): 307-310. (in Chinese). [18] LIU SH Y, JIA K N, WAN H P, et al. Inspection of the internal defects with different size in Ni and Ti additive manufactured components using laser ultrasonic technology[J]. Optics & Laser Technology, 2022, 146: 107543. [19] ALMOND D P, PICKERING S G. An analytical study of the pulsed thermography defect detection limit[J]. Journal of Applied Physics, 2012, 111(9): 093510. [20] ZHUO L J, YANG X, ZHU J G, et al. Size determination of interior defects by reconstruction of subsurface virtual heat flux for step heating thermography[J]. NDT & E International, 2023, 133: 102734. [21] WANG F, SHENG J, SFARRA S, et al. Multimode infrared thermal-wave imaging in non-destructive testing and evaluation (NDT&E): physical principles, modulated waveform, and excitation heat source[J]. Infrared Physics & Technology, 2023, 135: 104993. [22] NAYAR S K, IKEUCHI K, KANADE T. Surface reflection: physical and geometrical perspectives[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 1991, 13(7): 611-634. [23] 张青树, 齐韦. 冷轧带钢表面形貌测试及其粗糙度均匀性控制研究[J]. 轧钢,2022,39(5):103-107.ZHANG Q SH, QI W. Study on surface profile test and roughness uniformity control of cold rolled strip[J]. Steel Rolling, 2022, 39(5): 103-107. (in Chinese). [24] 杨甬英, 陆春华, 梁蛟, 等. 光学元件表面缺陷的显微散射暗场成像及数字化评价系统[J]. 光学学报,2007,27(6):1031-1038. doi: 10.3321/j.issn:0253-2239.2007.06.015YANG Y Y, LU CH H, LIANG J, et al. Microscopic dark-field scattering imaging and digitalization evaluation system of defects on optical devices precision surface[J]. Acta Optica Sinica, 2007, 27(6): 1031-1038. (in Chinese). doi: 10.3321/j.issn:0253-2239.2007.06.015 [25] LI X C, WU Q Q, XIAO B P, et al. High-speed and robust infrared-guiding multiuser eye localization system for autostereoscopic display[J]. Applied Optics, 2020, 59(14): 4199-4208. [26] 吴海滨, 魏喜盈, 刘美红, 等. 结合空洞卷积和迁移学习改进YOLOv4的X光安检危险品检测[J]. 中国光学,2021,14(6):1417-1425.WU H B, WEI X Y, LIU M H, et al. Improved YOLOv4 for dangerous goods detection in X-ray inspection combined with atrous convolution and transfer learning[J]. Chinese Optics, 2021, 14(6): 1417-1425. (in Chinese). [27] 张寅, 朱桂熠, 施天俊, 等. 基于特征融合与注意力的遥感图像小目标检测[J]. 光学学报,2022,42(24):2415001.ZHANG Y, ZHU G Y, SHI T J, et al. Small object detection in remote sensing images based on feature fusion and attention[J]. Acta Optica Sinica, 2022, 42(24): 2415001. (in Chinese). [28] 张印辉, 庄宏, 何自芬, 等. 氨气泄漏混洗自注意力轻量化红外检测[J]. 中国光学(中英文),2023,16(3):607-619.ZHENG Y H, ZHUANG H, HE Z F, et al. Lightweight infrared detection of ammonia leakage using shuffle and self-attention[J]. Chinese Optics, 2023, 16(3): 607-619. (in Chinese). [29] 刘彦磊, 李孟喆, 王宣宣. 轻量型YOLOv5s车载红外图像目标检测[J]. 中国光学(中英文),2023,16(5):1045-1055.LIU Y L, LI M ZH, WANG X X. Lightweight YOLOv5s vehicle infrared image target detection[J]. Chinese Optics, 2023, 16(5): 1045-1055. (in Chinese). [30] VILLARRAGA-GÓMEZ H, SMITH S T. Effect of geometric magnification on dimensional measurements with a metrology-grade X-ray computed tomography system[J]. Precision Engineering, 2022, 73: 488-503. -

下载:

下载: