Image aided measurement of the automotive brake master cylinder compensation hole normal line

-

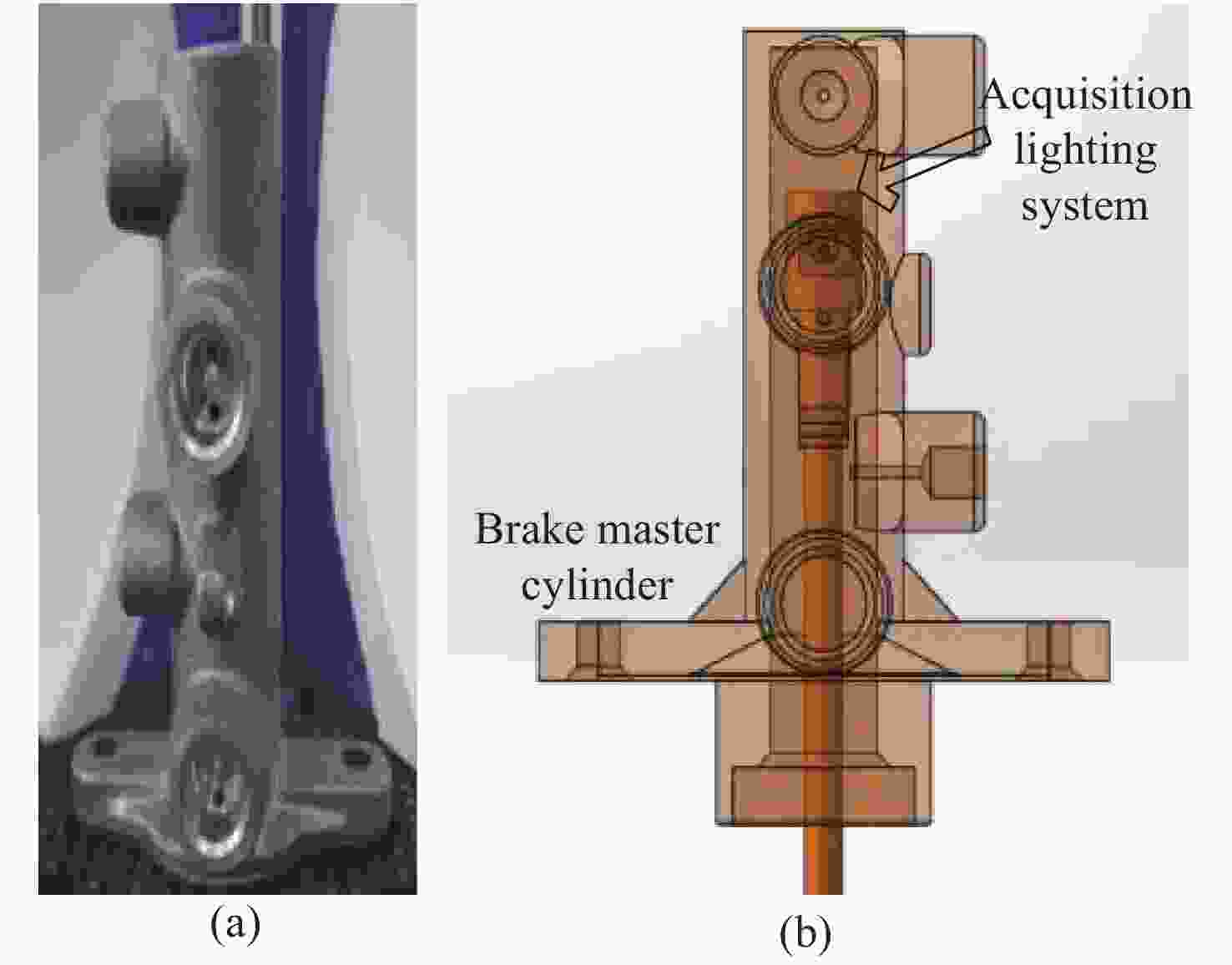

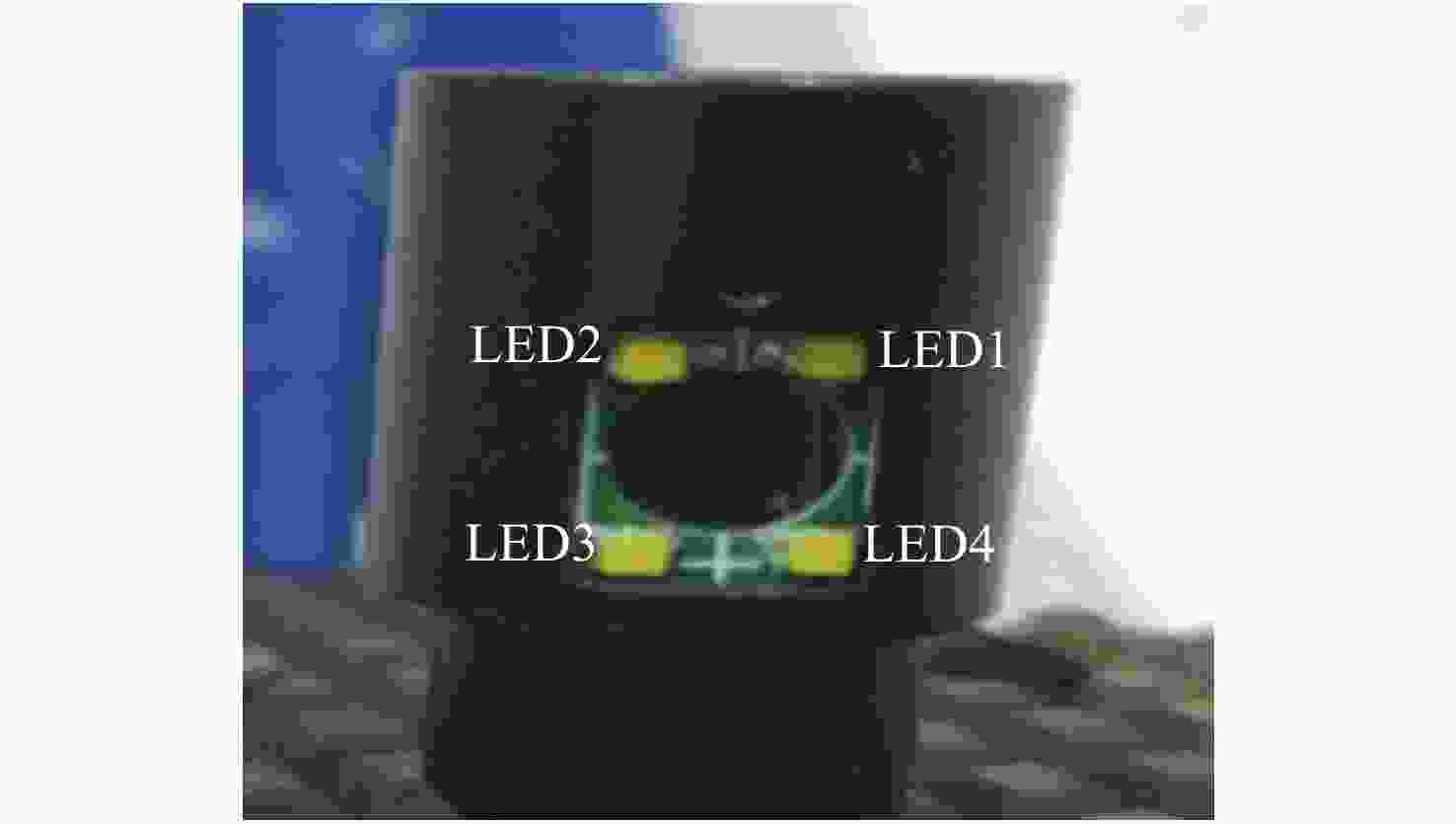

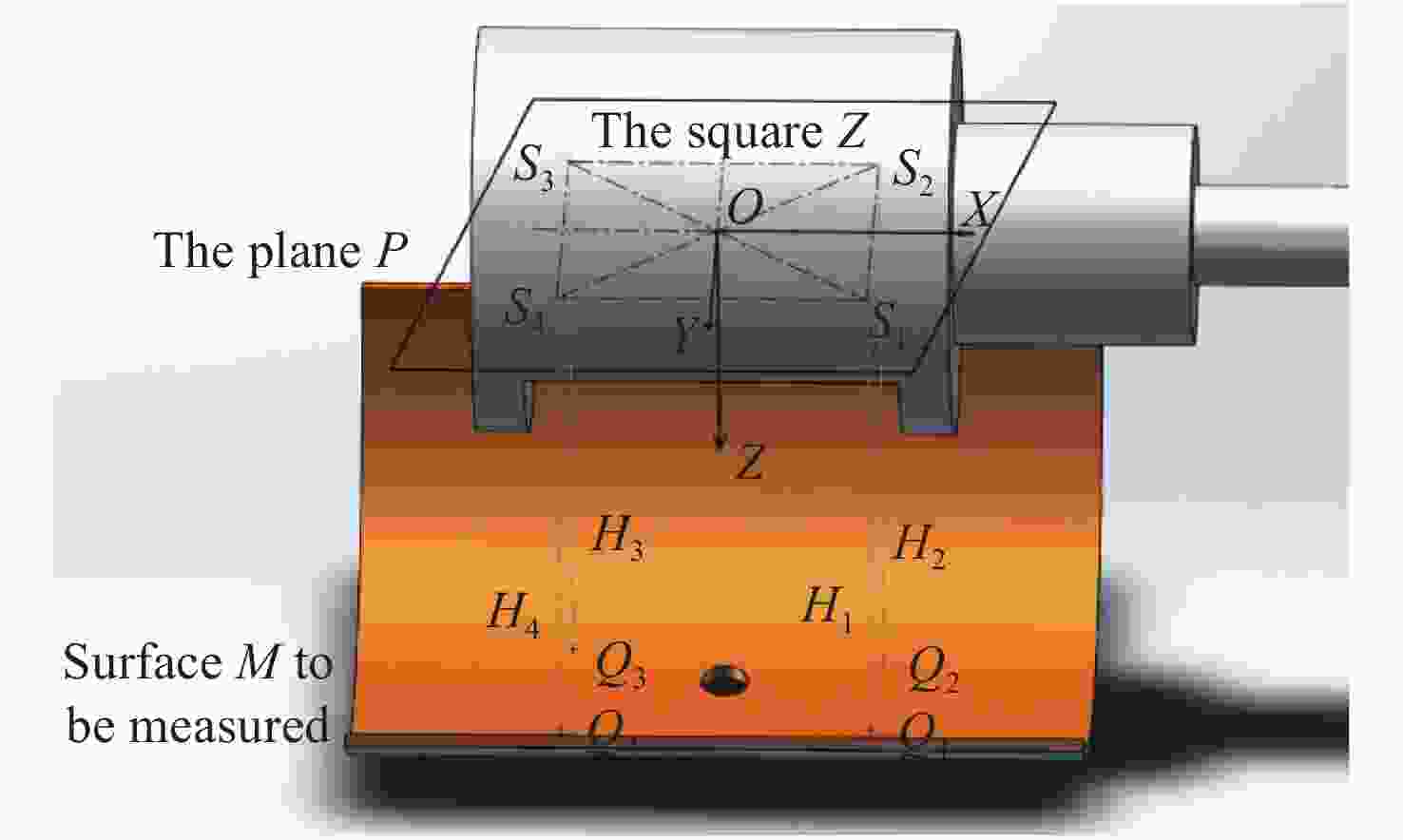

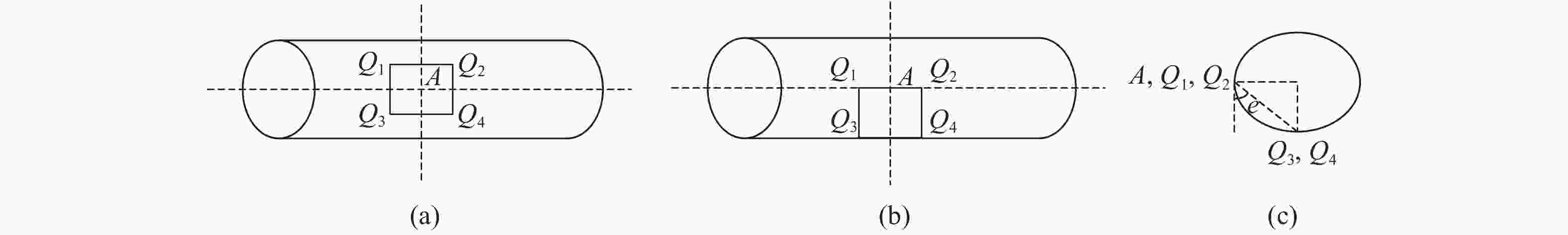

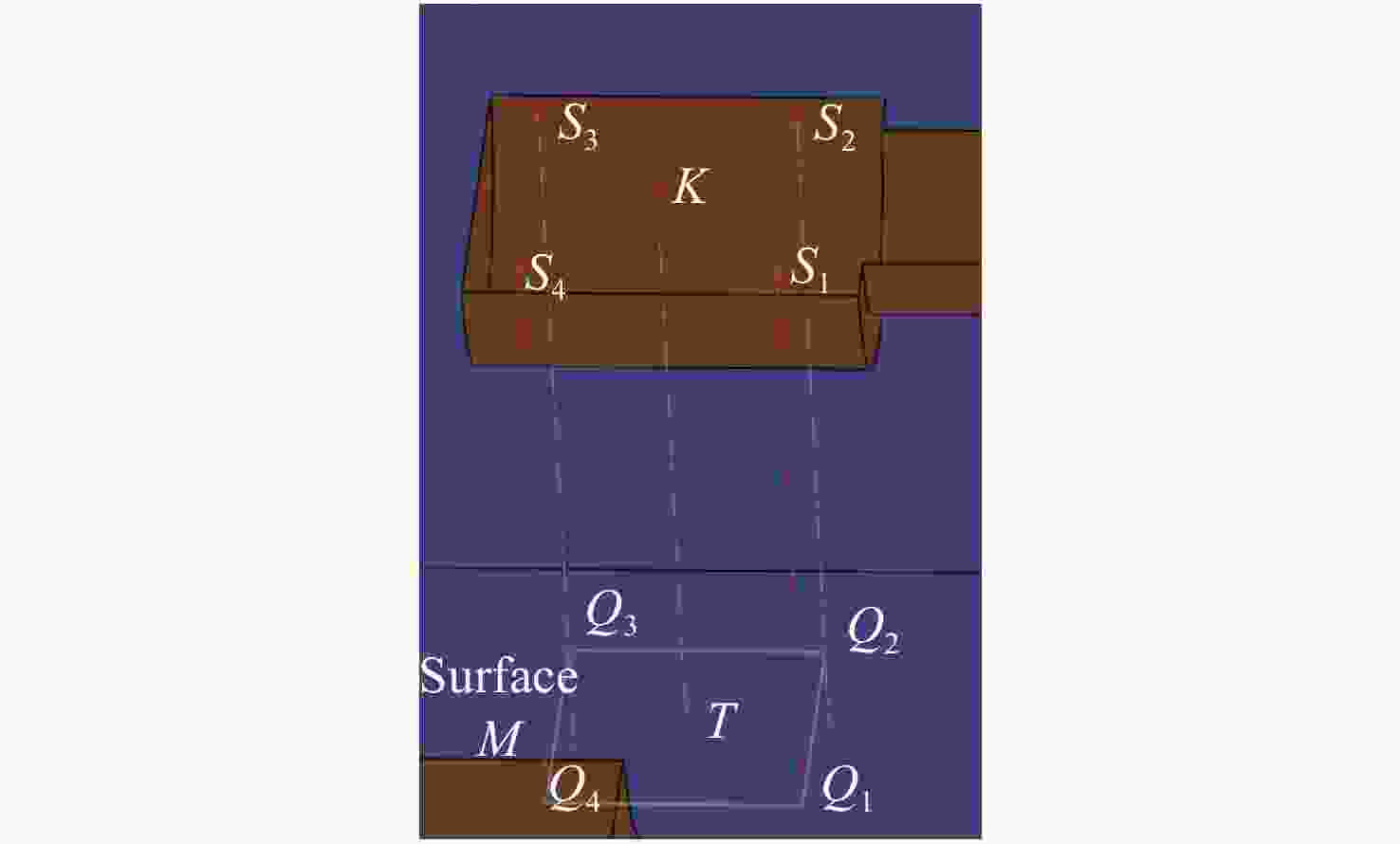

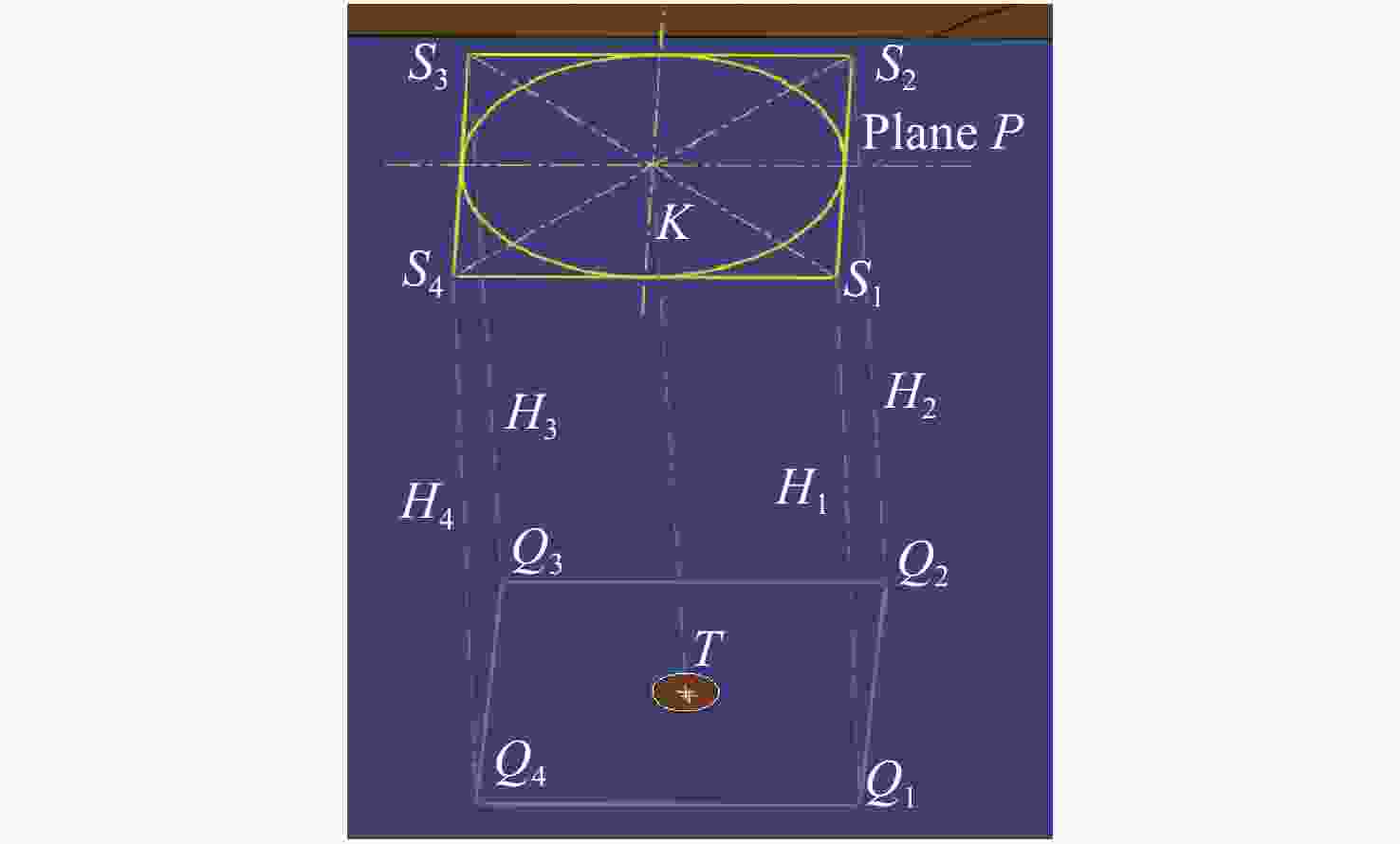

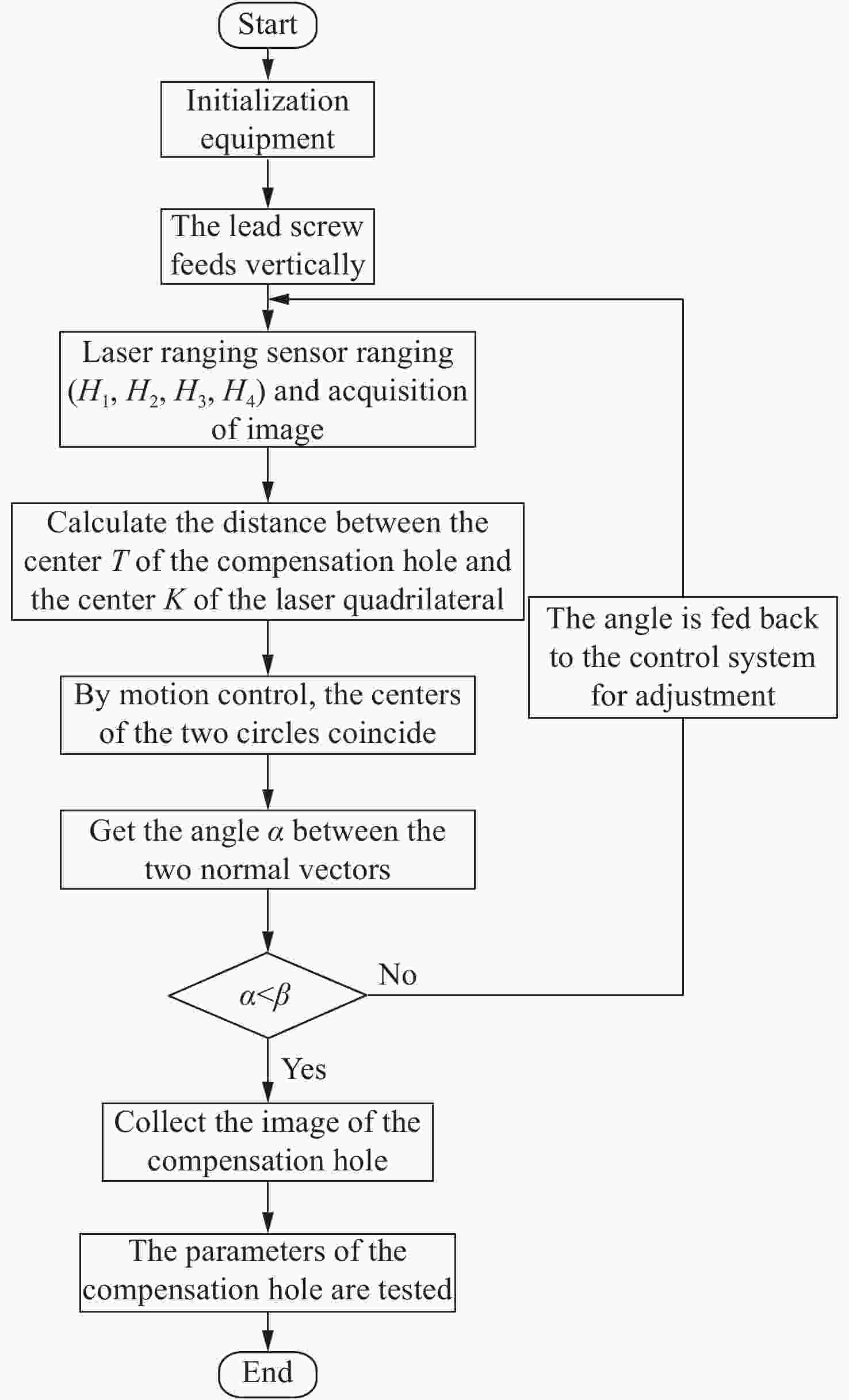

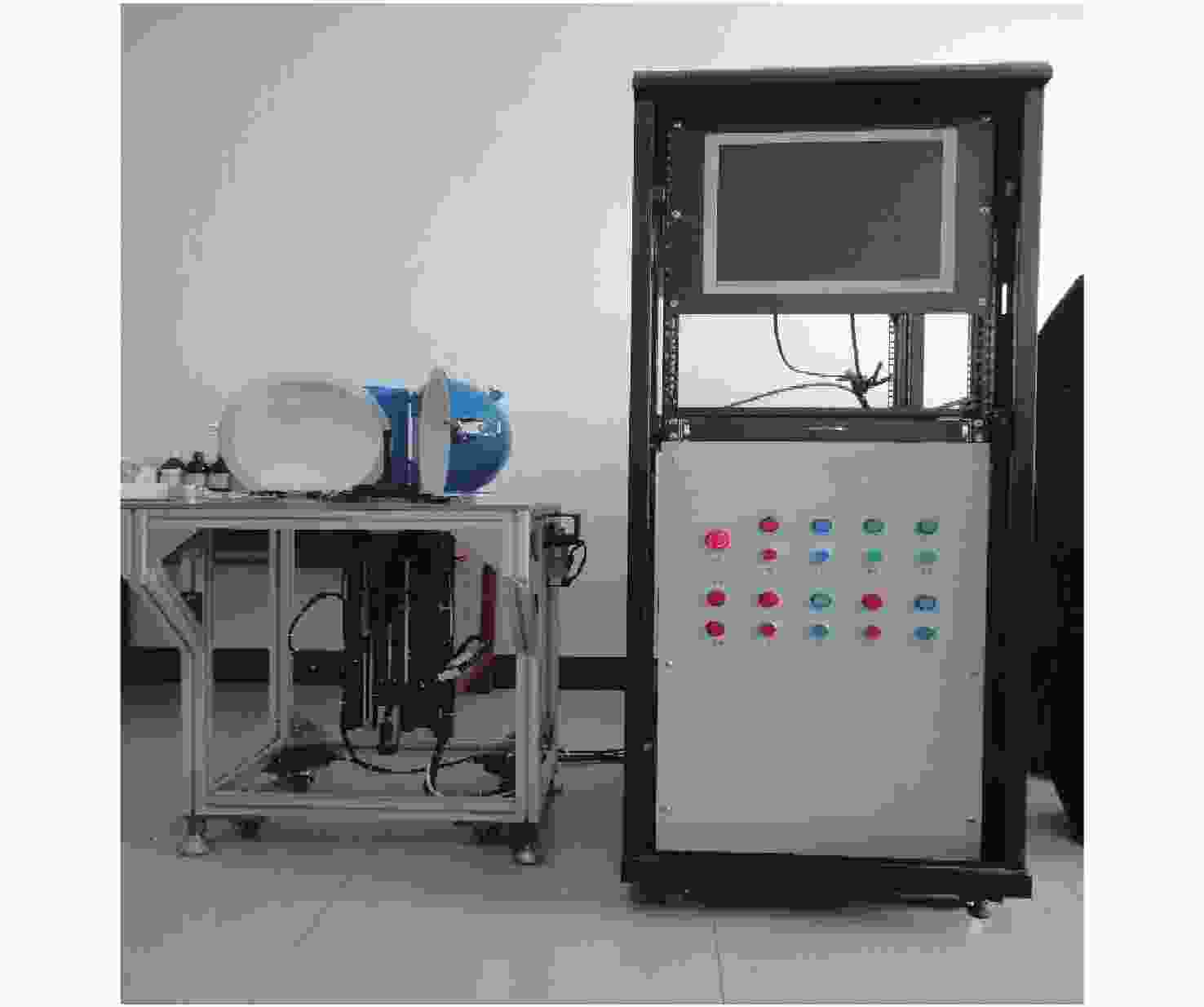

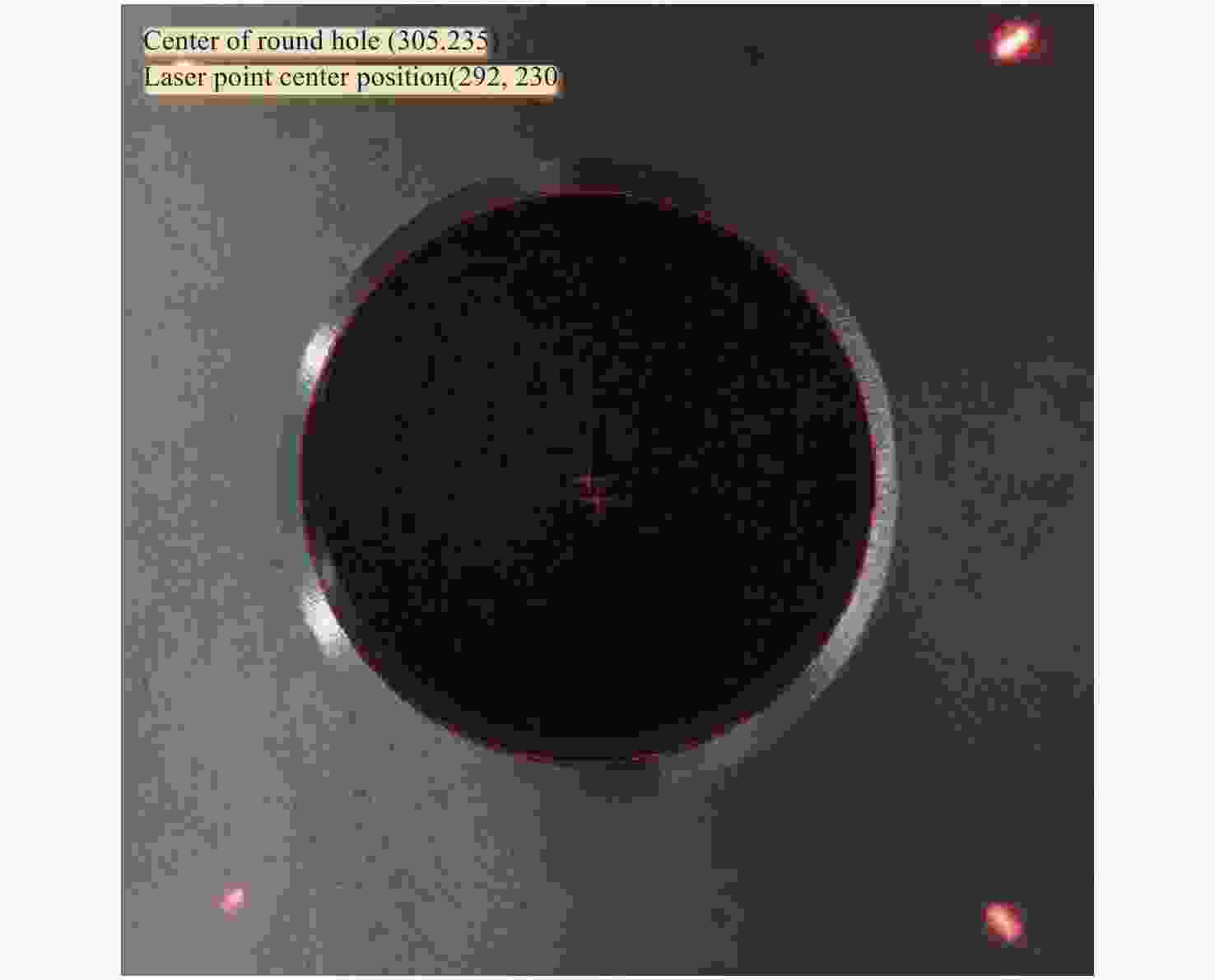

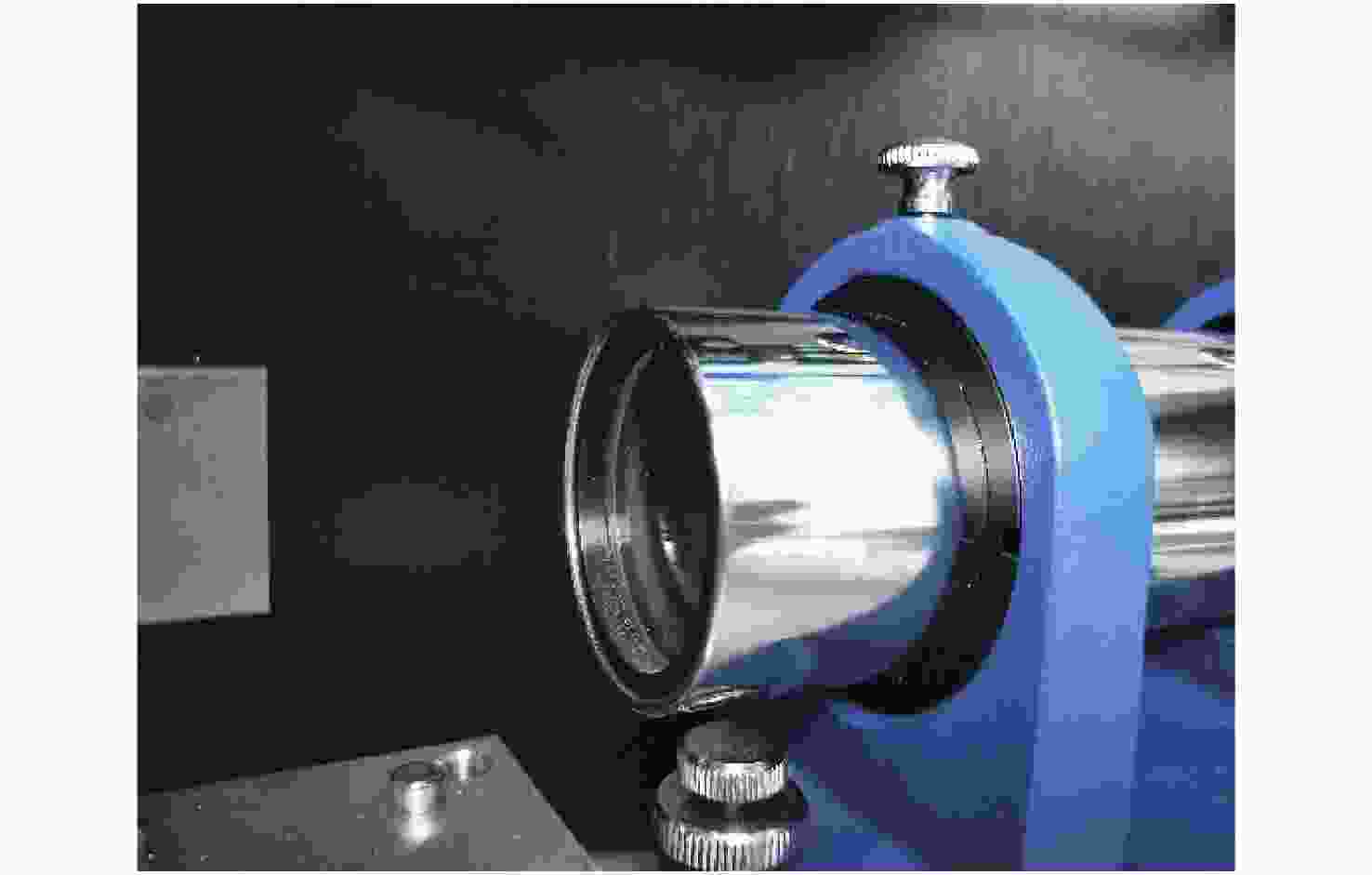

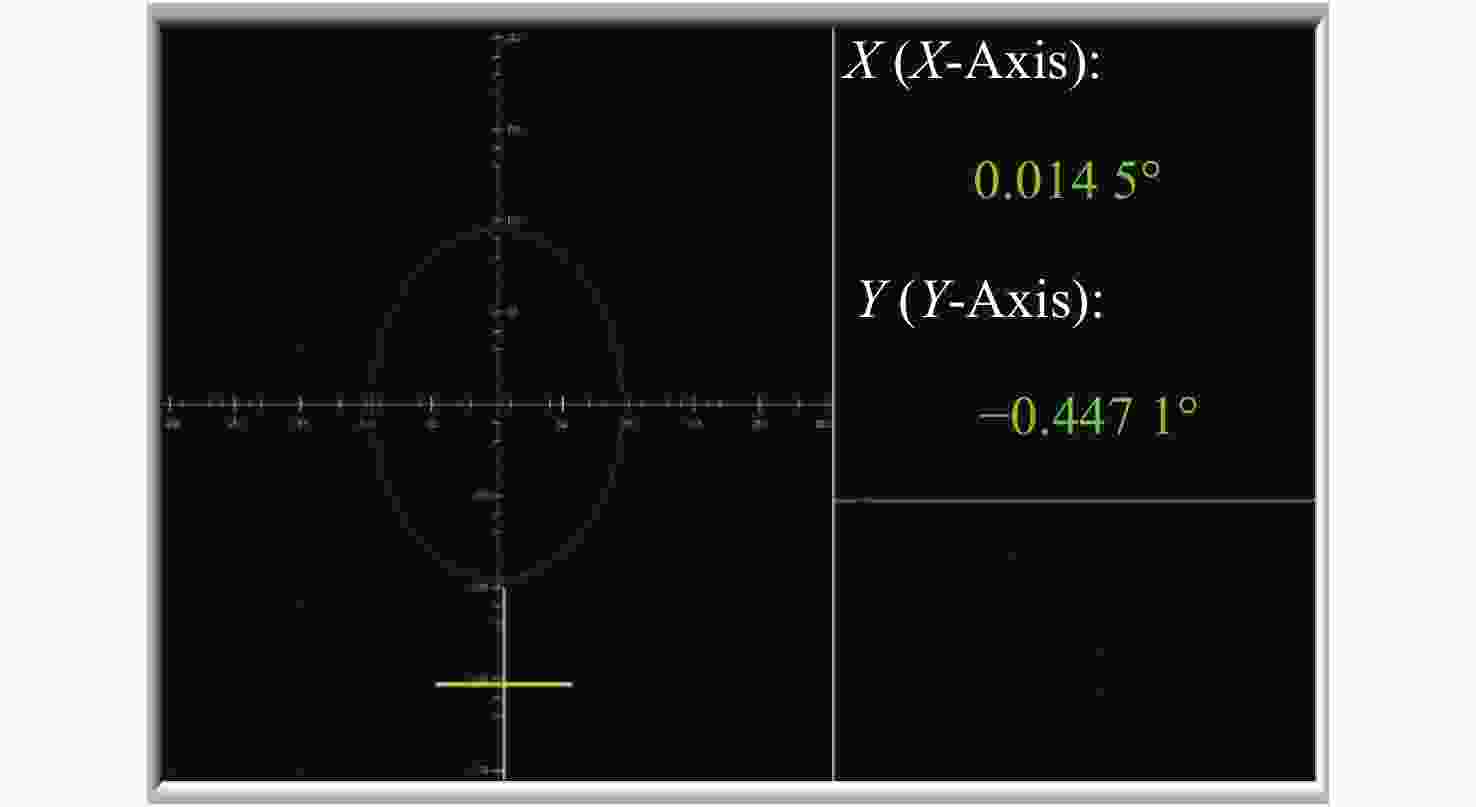

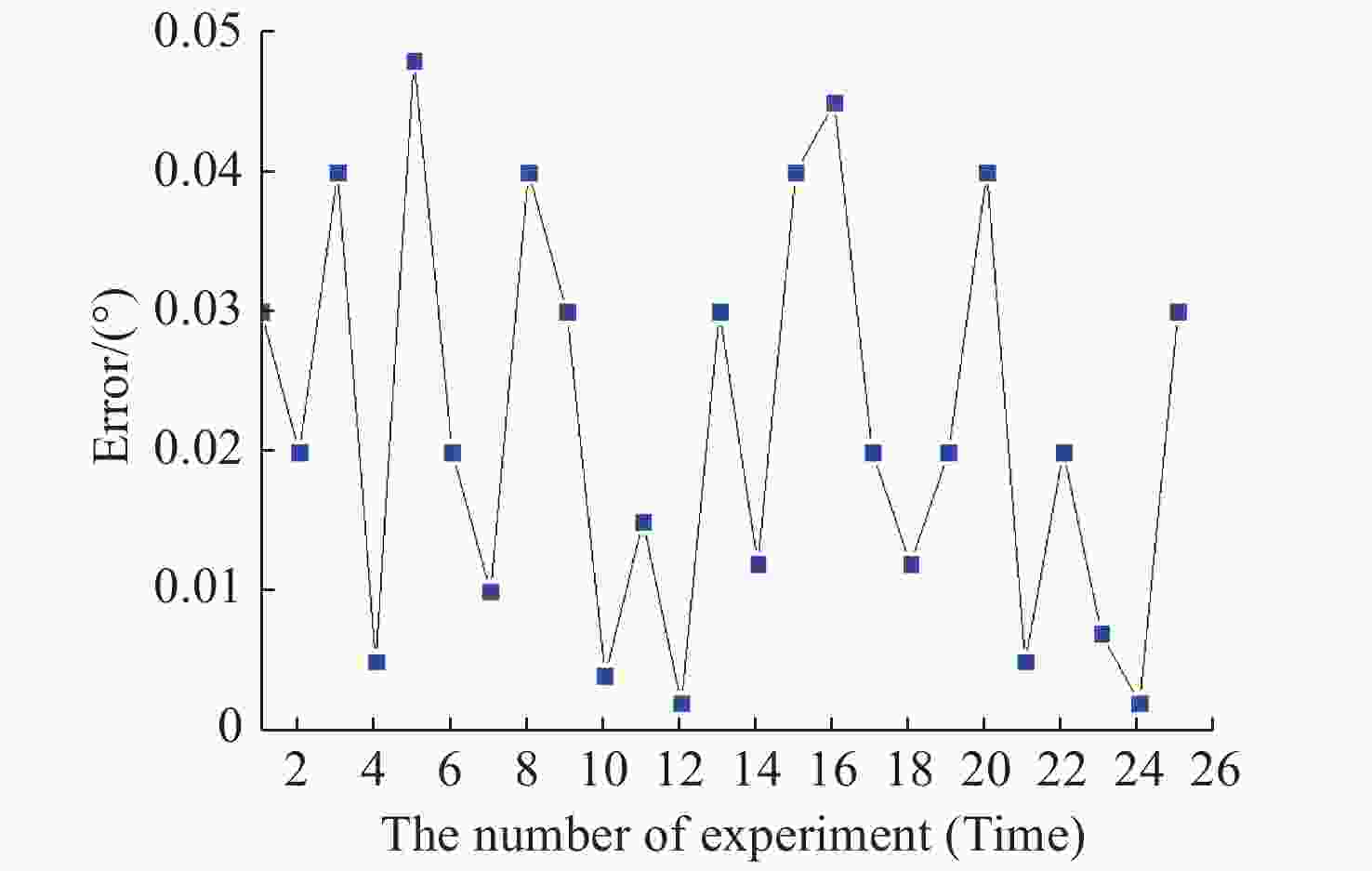

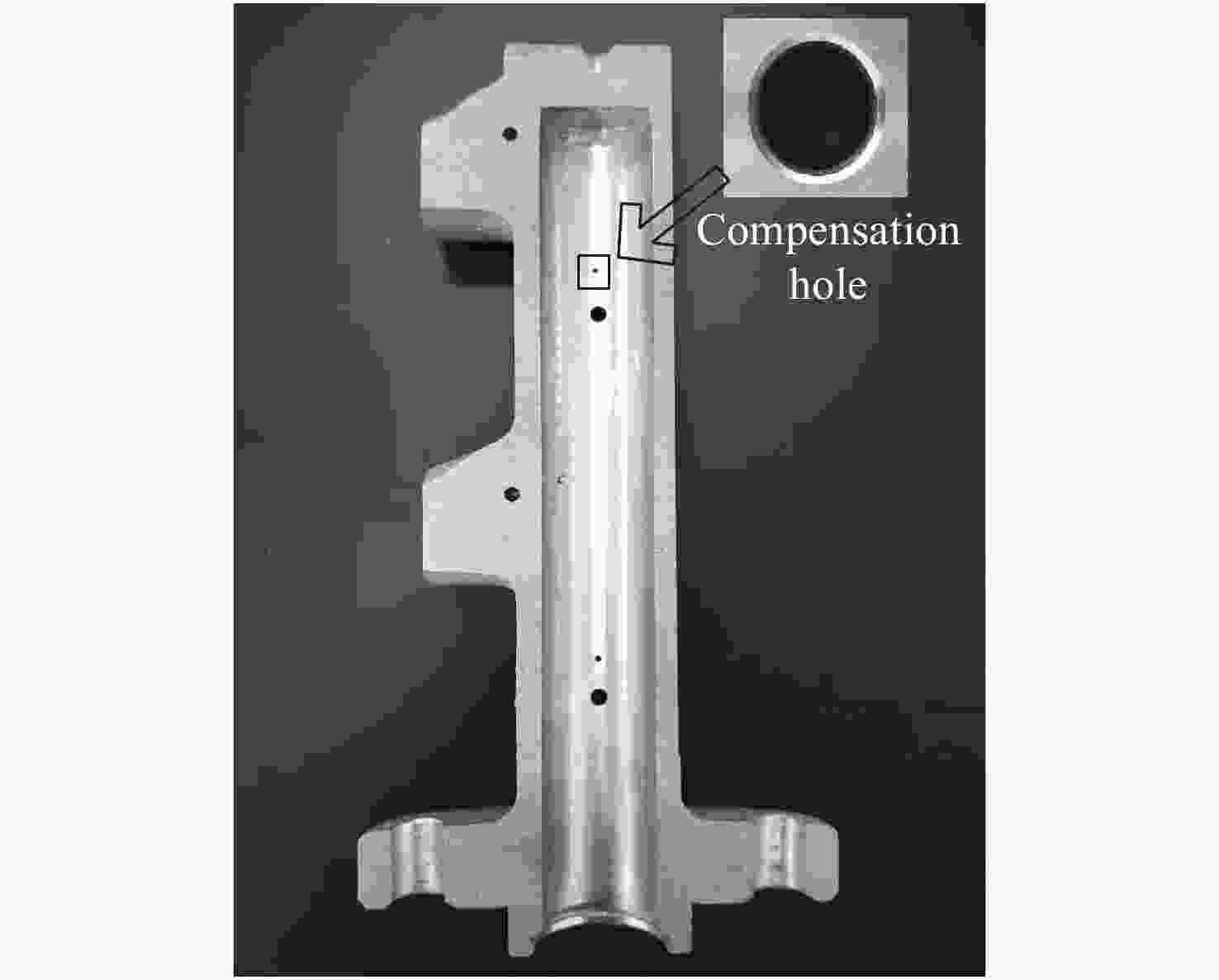

摘要: 随着道路上汽车的增多,汽车制动系统的可靠性受到越来越多的关注,基于机器视觉的汽车制动主缸补偿孔参数检测精度,是决定汽车安全性和停车可靠性的关键技术,补偿孔作为汽车制动主缸的重要组成部分,可以起到调节汽车制动主缸储液罐与压力室中制动液的重要作用,其尺寸精度和加工质量受到严格的控制,因此如何准确的获取补偿孔的图像是补偿孔参数检测的首要问题。通过将飞机钻铆孔法线找正的方法引入到图像获取中,将四点微平面法线检测方法与图像处理相结合,实现高效高精度的法线找正。实验表明,本文算法法线找正精度高于0.05°,优于传统检测精度的0.5°,检测时间小于1 s。本文提出的算法在满足精度要求的情况下,算法简单,实时性高,同时具有较好的鲁棒性,满足制动主缸生产工业现场对于检测速度和精度的要求。Abstract: With the increase in cars on the road, the reliability of automobile braking systems has received increasing attention. The detection accuracy of the compensation hole’s parameters of an automobile’s brake master cylinder based on machine vision is key to determining automobile safety and the reliability of parking technology. As an important part of automobile brake master cylinders, the compensation hole can play an important role in regulating the brake fluid in its reservoir and pressure chamber. Its dimensional accuracy and processing quality are strictly controlled, so accurately obtaining an image of the compensation hole is a priority in compensation hole parameter detection. By introducing the correction method of plane drilling rivet hole normal line into the image acquisition process, the four-point micro-plane normal line detection method is combined with image processing to realize high-efficiency and high-precision normal line correction. Experiments show that the algorithm's normal alignment accuracy is higher than 0.05°, which is better than the traditional detection accuracy of 0.5°, and the detection time is less than 1 s. The algorithm proposed in this paper is simple and has good real-time performance while meeting accuracy requirements. It also has good robustness and meets the requirements of the brake master cylinder production industry for detection speed and accuracy.

-

Key words:

- laser ranging /

- normal detection /

- gradient hough transform /

- ellipse fitting

-

表 1 4种汽车制动主缸补偿方法的孔不圆度、误差大小和时间

Table 1. Out-of-roundness, error and time of compensating hole of automobile brake master cylinder by four methods

Detection parameter The elliptical coefficient

(A,B,C,D,E,F)Maximum radius

${R_{\max } }/{\rm{pixel}}$Minimum radius

${R_{\min } }/{\rm{pixel}}$Out of roundness

$\delta {\rm{/}}$%The normal

error /(°)Time $t/{\rm{ms} }$ Taken directly (0.5,0,0.9,−269.8,−437.4,64727) 220.284 175.147 0.2276 0.4572 120 Micro plane (0.6,0,0.8,−320.1,−401.2,68722) 195.672 174.687 0.1133 0.1871 680 Surface fitting (0.7,0,0.7,−372.6,−345.2,70916) 180.547 176.398 0.0232 0.0857 1276 Proposed algorithm (0.7,0,0.7,−366.6,−359.8,71460) 176.536 175.248 0.0073 0.0124 710 -

[1] YU ZH L, TAN W. Measuring instrument for compensated hole of hydraulic brake master cylinder based on machine vision[C]. Proceedings of 2010 International Conference on Mechanic Automation and Control Engineering, IEEE, 2010. [2] IOVENITTI P G, MUTAPCIC E, NAGARAJAH C R. Positioning and orienting a drill axis on a curved surface[J]. The International Journal of Advanced Manufacturing Technology, 2001, 17(7): 484-488. doi: 10.1007/s001700170148 [3] SHAN Y C, HE N, LI L, et al.. Realization of spindle prompt normal posture alignment for assembly holemaking on large suspended panel[C]. Proceedings of the Third International Conference on Measuring Technology and Mechatronics Automation, IEEE, 2011: 956-960. [4] 薛汉杰, 张敬佩. 蒙皮类部件钻孔法向的测量和调整[J]. 航空制造技术,2010(23):60-62, 66. doi: 10.3969/j.issn.1671-833X.2010.23.010XUE H J, ZHANG J P. Normal measurement and adjustment for skin drilling[J]. Aeronautical Manufacturing Technology, 2010(23): 60-62, 66. (in Chinese) doi: 10.3969/j.issn.1671-833X.2010.23.010 [5] DU ZH C, YAO Y B. Measurement method for evaluating normal direction of surface for digital drilling and riveting[C]. SAE 2012 Aerospace Manufacturing and Automated Fastening Conference & Exhibition, SAE, 2012. [6] 杨滨赫, 蔡引娣, 文志祥, 等. 长距离激光测量中光束漂移的自动补偿[J]. 光学 精密工程,2020,28(11):2393-2402. doi: 10.37188/OPE.20202811.2393YANG B H, CAI Y D, WEN ZH X, et al. Automatic compensation method for beam drift in long-distance laser measurement[J]. Optics and Precision Engineering, 2020, 28(11): 2393-2402. (in Chinese) doi: 10.37188/OPE.20202811.2393 [7] PHAN N D M P, QUINSAT Y, LARTIGUE C. Optimal scanning strategy for on-machine inspection with laser-plane sensor[J]. The International Journal of Advanced Manufacturing Technology, 2019, 103(9-12): 4563-4576. doi: 10.1007/s00170-019-03877-x [8] NORGIA M, CAVEDO F, PESATORI A, et al.. Short-range contactless laser sensor[C]. Proceedings of 2017 IEEE International Instrumentation and Measurement Technology Conference, IEEE, 2017. [9] 秦现生, 汪文旦, 楼阿莉, 等. 大型壁板数控钻铆的三点快速调平算法[J]. 航空学报,2007,28(6):1455-1460. doi: 10.3321/j.issn:1000-6893.2007.06.031QIN X SH, WANG W D, LOU A L, et al. Three-point bracket regulation algorithm for drilling and riveting of aerofoil[J]. Acta Aeronautica et Astronautica Sinica, 2007, 28(6): 1455-1460. (in Chinese) doi: 10.3321/j.issn:1000-6893.2007.06.031 [10] 西安交通大学, 西安瑞特快速制造工程研究有限公司. 基于三点微平面式法向检测方法: 中国, CN101957175A[P]. 2011-01-26.Xi′an Jiaotong University, Xi'an Ruite Rapid Manufacturing Engineering Research Co., Ltd. Three-point micro-plane-based normal detection method: CN, CN101957175A[P]. 2011-01-26. (in Chinese) [11] 公茂震, 袁培江, 王田苗, 等. 航空制孔机器人末端垂直度智能调节方法[J]. 北京航空航天大学学报,2012,38(10):1400-1404.GONG M ZH, YUAN P J, WANG T M, et al. Intelligent verticality-adjustment method of end-effector in aeronautical drilling robot[J]. Journal of Beijing University of Aeronautics and Astronautics, 2012, 38(10): 1400-1404. (in Chinese) [12] 应高明, 王仲奇, 康永刚, 等. 飞机壁板自动钻铆法向量测量方法研究[J]. 机床与液压,2010,38(23):1-4, 8. doi: 10.3969/j.issn.1001-3881.2010.23.001YING G M, WANG ZH Q, KANG Y G, et al. Study on normal vector measurement method in auto-drilling & riveting of aircraft panel[J]. Machine Tool &Hydraulics, 2010, 38(23): 1-4, 8. (in Chinese) doi: 10.3969/j.issn.1001-3881.2010.23.001 [13] TIAN W, ZHOU W X, ZHOU W, et al. Auto-normalization algorithm for robotic precision drilling system in aircraft component assembly[J]. Chinese Journal of Aeronautics, 2013, 26(2): 495-500. doi: 10.1016/j.cja.2013.02.029 [14] MITRA N J, NGUYEN A, GUIBAS L. Estimating surface normals in noisy point cloud data[J]. International Journal of Computational Geometry &Applications, 2004, 14(4-5): 261-276. [15] ROWELL E, LOUDERMILK E L, SEIELSTAD C, et al. Using simulated 3D surface fuelbeds and terrestrial laser scan data to develop inputs to fire behavior models[J]. Canadian Journal of Remote Sensing, 2016, 42(5): 443-459. doi: 10.1080/07038992.2016.1220827 [16] EDGEWORTH R M. Applications of surface normal measurements to coordinate metrology[D]. Charlotte: The University of North Carolina at Charlotte, 2000. [17] CALDERON F, RUIZ U, RIVERA M. Surface-normal estimation with neighborhood reorganization for 3D reconstruction[C]. Proceedings of the 12th Iberoamerican Congress on Pattern Recognition, Springer, 2007: 321-330. [18] 姜春英, 牛祥鑫, 张诚然, 等. 机器人航空铆接的视觉定位方法研究[J]. 航空制造技术,2018,61(4):55-59.JIANG CH Y, NIU X X, ZHANG CH R, et al. Research on visual positioning method for robot aeronautical riveting[J]. Aeronautical Manufacturing Technology, 2018, 61(4): 55-59. (in Chinese) [19] 毕超, 郝雪, 李迪. 飞机蒙皮法线方向的视觉检测技术研究[J]. 传感技术学报,2020,33(9):1259-1265. doi: 10.3969/j.issn.1004-1699.2020.09.006BI CH, HAO X, LI D. Study on vision inspection technology for normal direction of aircraft surfaces[J]. Chinese Journal of Sensors and Actuators, 2020, 33(9): 1259-1265. (in Chinese) doi: 10.3969/j.issn.1004-1699.2020.09.006 [20] 陈允全, 李泷杲, 黄翔, 等. 基于机器人的飞机大型结构三维自动化检测方法[J]. 航空制造技术,2019,62(10):51-57.CHEN Y Q, LI SH G, HUANG X, et al. Three-dimensional automatic detection method for large-scale structure of aircraft based on robot[J]. Aeronautical Manufacturing Technology, 2019, 62(10): 51-57. (in Chinese) [21] 梁杰, 毕树生. 制孔执行器的安装方式对机器人性能的影响[J]. 机械工程学报,2010,46(21):13-18. doi: 10.3901/JME.2010.21.013LIANG J, BI SH SH. Effects of drill end effector’s mounted method on the robot performance[J]. Journal of Mechanical Engineering, 2010, 46(21): 13-18. (in Chinese) doi: 10.3901/JME.2010.21.013 [22] 曲巍崴, 董辉跃, 柯映林. 机器人辅助飞机装配制孔中位姿精度补偿技术[J]. 航空学报,2011,32(10):1951-1960.QU W W, DONG H Y, KE Y L. Pose accuracy compensation technology in robot-aided aircraft assembly drilling process[J]. Acta Aeronautica et Astronautica Sinica, 2011, 32(10): 1951-1960. (in Chinese) [23] 杜兆才. 数字化钻铆的曲面法向测量方法[J]. 航空制造技术,2011(22):108-111. doi: 10.3969/j.issn.1671-833X.2011.22.023DU ZH C. Measurement method for evaluating normal direction of surface for digital drilling and riveting[J]. Aeronautical Manufacturing Technology, 2011(22): 108-111. (in Chinese) doi: 10.3969/j.issn.1671-833X.2011.22.023 [24] 王红平, 曹国华, 姜涛, 等. 一种汽车制动缸补偿孔形位尺寸检测方法的研究[J]. 机械设计与制造,2009(9):120-122. doi: 10.3969/j.issn.1001-3997.2009.09.049WANG H P, CAO G H, JIANG T, et al. A form and position measurement on brake cylinder offset hole of automobile[J]. Machinery Design &Manufacture, 2009(9): 120-122. (in Chinese) doi: 10.3969/j.issn.1001-3997.2009.09.049 [25] SELS S, RIBBENS B, VANLANDUIT S, et al. Camera calibration using gray code[J]. Sensors, 2019, 19(2): 246. doi: 10.3390/s19020246 [26] LÓPEZ M, MARÍ R, GARGALLO P, et al.. Deep single image camera calibration with radial distortion[C]. Proceedings of 2019 IEEE/CVF Conference on Computer Vision and Pattern Recognition, IEEE, 2019. [27] 庞云龙, 刘佳, 王林. BCF-92 POF端面不圆度测量及引用[J]. 光通信技术,2020,44(7):59-62.PANG Y L, LIU J, WANG L. BCF-92 POF end face out-of-roundness measurement and application[J]. Optical Communication Technology, 2020, 44(7): 59-62. (in Chinese) [28] 陈若珠, 孙岳. 基于最小二乘法的椭圆拟合改进算法研究[J]. 工业仪表与自动化装置,2017(2):35-38, 46. doi: 10.3969/j.issn.1000-0682.2017.02.008CHEN R ZH, SUN Y. The study of an improved randomized algorithm for detecting ellipses based on least square approach[J]. Industrial Instrumentation &Automation, 2017(2): 35-38, 46. (in Chinese) doi: 10.3969/j.issn.1000-0682.2017.02.008 [29] 闫蓓, 王斌, 李媛. 基于最小二乘法的椭圆拟合改进算法[J]. 北京航空航天大学学报,2008,34(3):295-298.YAN B, WANG B, LI Y. Optimal ellipse fitting method based on least-square principle[J]. Journal of Beijing University of Aeronautics and Astronautics, 2008, 34(3): 295-298. (in Chinese) [30] 姜涛, 张桂林, 高俊鹏. 制动主缸补偿孔位置检测误差分析与补偿[J]. 光学 精密工程,2020,28(5):1094-1100.JIANG T, ZHANG G L, GAO J P. Error analysis and compensation in position measurement of brake master cylinder compensation hole[J]. Optics and Precision Engineering, 2020, 28(5): 1094-1100. (in Chinese) -

下载:

下载: