Research on manufacturing method of non-rotationally symmetrical aspheric surface with high accuracy

-

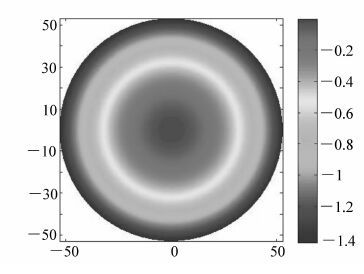

摘要: 本文提出一种高精度非回转对称非球面加工方法。首先,通过范成法铣磨出非回转对称非球面的最佳拟合球;然后,利用古典抛光修正小磨头确定抛光难以修正的中频误差;最后,利用高精度气囊抛光设备(IRP)精确对位精修面形,在不引入额外中频误差条件下,通过高精度对位检测技术实现非回转对称非球面高精度加工。将该方法应用于定点曲率半径为970.737 mm、k=-1、口径为106 mm三次非球面加工,降低了加工难度,提高了加工精度,面形误差收敛到1/30λ(RMS)。实验结果验证了本文加工方法的正确性和可行性,对高精度非回转对称非球面加工具有一定的指导意义。Abstract: A novel manufacturing method of non-rotationally symmetrical aspheric surface with high accuracy is proposed in this paper. First, a optimum fit sphere of non-rotationally symmetrical asphere is ground through generating cutting, which is then polished through triditional polishing method in order to remove mid-spatial-frequency errors that cannot be realized through sub-aperture polishing tool. Finally, bonnet polishing method(IRP) is used for corrective polishing without generating extra mid-spatial-frequency errors in condition of high-accuracy positioning measurement technology. This method is employed in the manufacuring of a third-order aspheric surface with parameters of ROC=970.737 mm, k=-1 and D=106 mm. After several polishing iterations, the figure accuracy can be converged to 1/30λ(RMS). The correctness and feasibility of the manufacturing method are proved. This method would be meaningful in manufacturing non-rotationally symmetrical aspheric surface with small deviation in the future.

-

Key words:

- non-rotationally symmetrical /

- aspheric surface /

- bonnet polishing /

- IRP polishing

-

表 1 本文选用的非球面参数

Table 1. Parameters of aspheric surface in this paper

C k D α β R φ -1/970.737 -1 53 0 0.001 2 53 101.4 -

[1] 王贵林,李圣怡,戴一帆.光学非球面复合加工机床的设计与精度分析[J].中国机械工程,2004,15(2):99-102.WANG G L,LI SH Y,DAI Y F. Design method and accuracy analysis of aspherical optical compound machine tool[J]. 中国机械工程,2004,15(2):99-102.(in Chinese) [2] 袁巨龙,吴喆,吕冰海,等.非球面超精密抛光技术研究现状[J].机械工程学报,2012,48(23):167-177.YUAN J L,WU ZH,LV B H,et al.. Review on ultra-precision polishing technology of aspheric surface[J]. J. Mechanical Engineering,201248(23):167-177.(in Chinese) [3] 潘超,陈家璧,张荣福,等.用位相板实现景深延拓的原理与模拟实验研究[J].光子学报,2009,38(7):1679-1682.PAN CH,CHEN J B,ZHANG R F,et al.. Study on principle and simulation of extending of depth of field with phase plate[J]. Acta Photonica Sinica,2009,38(7):1679-1682.(in Chinese) [4] BEAUCAMP A,FREEMAN R,MORTON R,et al.. Removal of diamond-turning signatures on X-ray mandrels and metal optics by fluid-jet polishing[J]. SPIE,2008,7018:351-359. [5] GAO SH,KANG R K,GUO D M,et al.. Study on the subsurface damage distribution of the silicon wafer ground by diamond wheel[J]. Advanced Materials Research,2010,126-128:113-118. [6] SURATWALA T I,WONG L L,MILLER P E,et al.. Sub-surface mechanical damage distributions during grinding of fused silica[J]. J. Non-Crystalline Solids,2006,352(52-54):5601-5617. [7] 张健,代雷,王飞,等.小磨头自适应抛光抑制高精度非球面中频误差[J].光学学报,2013,33(8):0822022.ZHANG J,DAI L,WNAG F,et al.. Restraint of mid-spatial-frequency aspheric surface by small-tool aptive polishing[J]. Acta Optica Sinica,2013,33(8):0822022.(in Chinese) [8] 高松涛,王高文,张健,等.用计算全息图校正非球面的畸变[J].光学 精密工程,2013,21(8):1929-1935.GAO S T,WANG G W,ZHANG J,et al.. Correction of distortion in asphere testing with computer-generated hologram[J]. Opt. Precision Eng.,2013,21(8):1929-1935.(in Chinese) [9] 曲兴田,王宏一,樊成,等.重叠率螺旋线的非球面抛光轨迹规划[J].西安交通大学学报,2015,49(6):y1-y7.QU X T,WANG H Y,FAN CH,et al.. Uniform-overlap-rate spiral path for aspheric polishing[J]. J. Xi'an Jiaotong University,2015,49(6):y1-y7.(in Chinese) [10] 周旭升,李圣怡,戴一帆,等.光学表面中频误差的控制方法-确定区域修正法[J].光学 精密工程,2007,15(11):1668-1673.ZHOU X SH,LI SH Y,DAI Y F,et al.. Correcting errors indefinite area: a new method for controlling mid-spatial-frequency errors in optical surface[J]. Opt. Precision Eng.,2007,15(11):1668-1673.(in Chinese) [11] 邓伟杰,张峰,郑立功.边缘效应的去除函数模型及实验[J].红外与激光工程,2011,40(9):1473-1478.DENG W J,ZHANG F,ZHENG L G. Removal functionmodel and experiment of edge effect[J]. Infrared and Laser Engineering,2011,40(9):1743-1748.(in Chinese) [12] 孔繁星,于正林,朴承镐,等.基于UMAC加工非球面光学零件PVT控制轨迹研究[J].长春理工大学学报,2009,32(2):196-206.KONG F X,YU ZH L,PIAO CH H,et al.. J. Research on PVT control trajectory of processing aspheric optical parts based on UMAC[J]. J. Changchun University of Science and Technology,2009,32(2):196-206.(in Chinese) [13] 胡陈林,毕果,叶卉,等.光学元件磨削加工亚表面损伤检测研究[J].人工晶体学报2014,43(11):2929-2934.HU CH L,BI G,YE H,et al.. Research on detection of subsurface damage on grinding optical elements[J]. J. Synthetic Crystals,2014,43(11):2929-2934.(in Chinese) [14] GENIN F Y,SALLEO A,PISTOR T V,et al.. Role of light intensification by cracks in optical breakdown on surfaces[J]. J. American Ceramic Society,2001,18(10):2607-2616. [15] 王贵林.光学材料超精密研抛关键技术研究[D].长沙:国防科学技术大学,2002.WANG G L. A study on key techniques in ultraprecision lapping and polishing for optical SIC materials[D]. Changsha:National University of Defense Technology,2002.(in Chinese) [16] 马占龙,王君林.超高精度光学元件加工技术[J].红外与激光工程,42(6):1485-1490.MA ZH L,WANG J L. Ultra-precision optical fabrication technology[J]. Infrared and Laser Engineering,42(6):1485-1490.(in Chinese) -

下载:

下载: