Thermal deformation of high absorption chrome plated mirror irradiated by laser

-

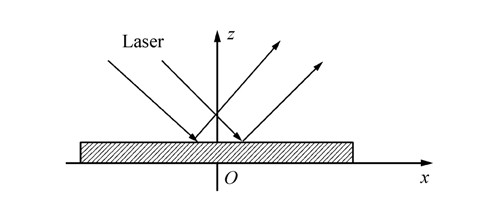

摘要: 为了分析激光辐照下反射镜热变形对光束质量的影响, 本文建立了激光光束45°角入射时镀铬介质高吸收镜的热固耦合模型, 对不同辐照光束下反射镜的热变形和镜体厚度对热变形的影响进行了分析, 并用哈特曼波前传感器对自由边界条件下的镜面热变形进行了检测。结果表明:吸收功率在0.085~0.185 W时, 镜面热变形随吸收功率的增加近似线性增加, 随辐照光斑的增加而减小;反射镜厚度在1~5 mm范围, 镜面热变形基本不变。在激光照射的初始阶段, 反射镜表面温度和热变形迅速增加, 在激光连续照射20 s后, 镜面温度增加量逐步变缓, 镜面热变形则在1 s以内就上升至0.27 μm, 之后变形量缓慢增加, 在100 s后达到相对稳定状态;关闭激光后, 镜面在120 s后恢复到初始状态。分析表明, 产生误差的因素主要为光斑大小和辐照光束入射角度。Abstract: In order to analyze the effect of thermal deformation of the mirror irradiated by laser beam on the beam quality, thermal-static structural coupled model of high absorption chrome plated mirror irradiated by laser beam with the incidence angle of 45° is built. Thermal deformation under different irradiation laser and the influence of mirror thickness on the deformation are analyzed. Then thermal deformation is detected with Hartmann wavefront sensor on free boundary condition. The results show that thermal deformation increases approximately linearly with the increase of the power absorbed at the range of 0.085-0.185 W. When the diameter of the facula increases, the deformation decreases. When mirror's thickness keeps in the range of 1~5 mm, the deformation merely keeps constant. In the initial stage of laser irradiation, the temperature and deformation increase rapidly. After 20 s, the increase of temperature on the mirror becomes slowly. The deformation increases to 0.27 μm in 1 s, and then increase slowly. The deformation will reach balance after 100 s. When the irradiation laser is removed, the mirror will return to the initial state after 120 s. The analysis result shows that the testing error is mainly caused by the error of the diameter of the facula and the incident angle of the laser.

-

-

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] -

下载:

下载: